Tightening device of circuit stringing

A wire tightening and wire racking technology, applied in overhead lines/cable equipment, adjusting/maintaining mechanical tension, etc., can solve problems such as poor safety and reliability, inconvenient maintenance, and difficulty in maintenance, and achieve high gear transmission efficiency and lifting speed. Fast and safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

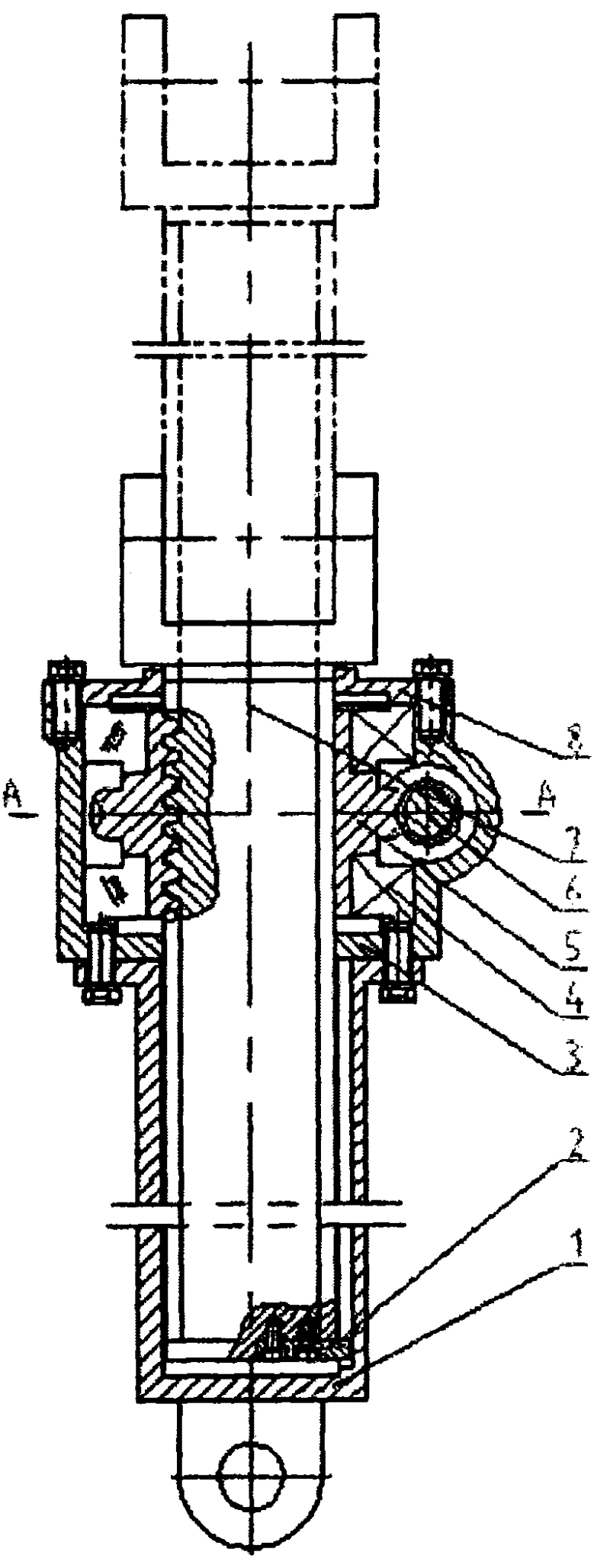

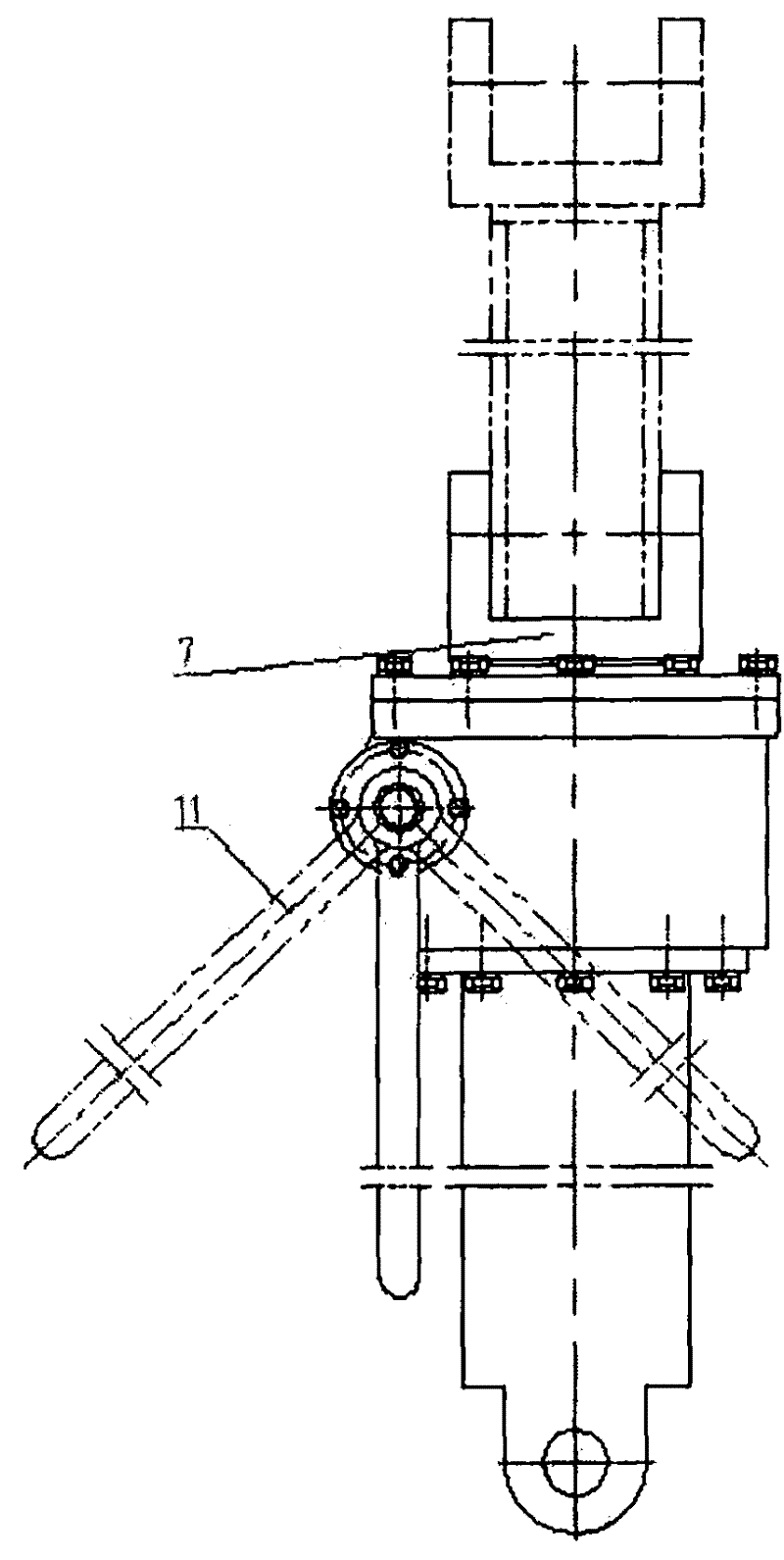

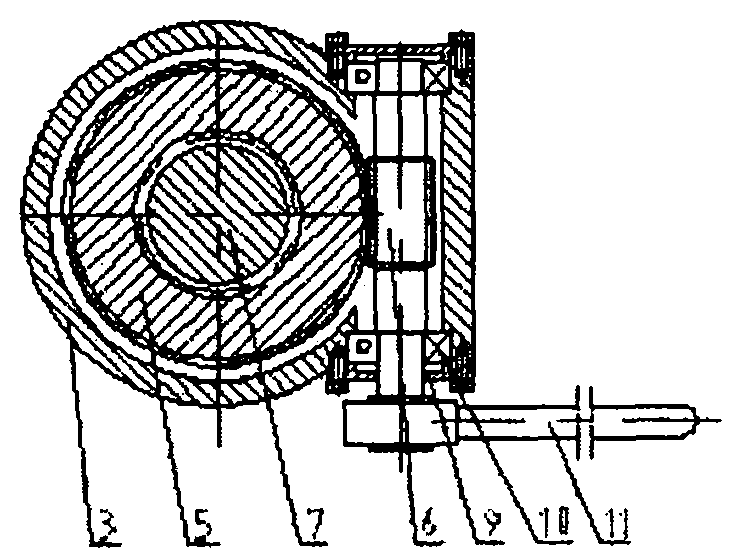

[0025] A line stringing tightening device, comprising a sleeve 1 and a trapezoidal screw 7 that can move relatively in the sleeve 1, one end of the trapezoidal screw 7 is connected with a wire tightening frame. One end of the sleeve is closed and fixed, and one end is provided with an opening through which the trapezoidal screw 7 protrudes, and a worm gear transmission part is formed in the opening end of the sleeve.

[0026] The worm gear transmission part includes a worm wheel (5) and a worm 6, and the worm wheel (5) is an annular hollow worm wheel for driving meshing gears respectively formed on the inner and outer ring peripheral surfaces, and the gear on the inner ring peripheral surface of the worm wheel (5) and The trapezoidal screw 7 is screwed and meshed for transmission. The gear on the outer ring surface of the worm wheel (5) is screwed with the worm 6 for meshing transmission. Thus, the rotation of the worm 6 drives the turbine (5) to rotate, so that the rotation of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com