Method for improving alignment precision after epitaxial growth

A technology of epitaxial growth and post-coating, which is applied in the field of improving the precision of post-coating of epitaxial growth, can solve the problem that the zero mark area cannot be measured, and achieve the effect of improving the precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

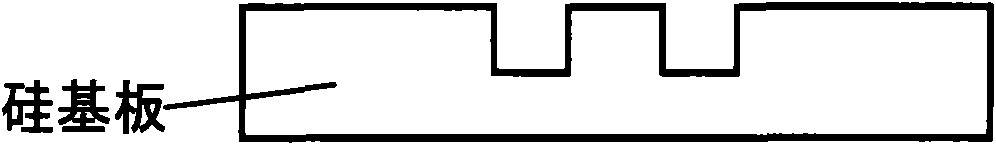

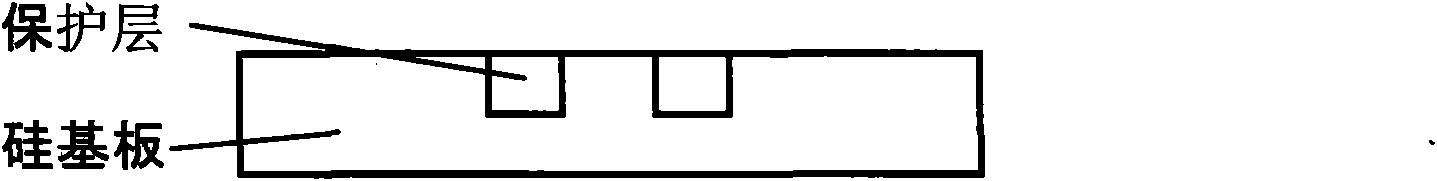

[0013] The method of the present invention utilizes the characteristic that the epitaxial layer is difficult to grow on some materials. After the formation of the ordinary zero mark, the protective layer is filled and etched back, so that the zero mark is protected by the protective layer. In the subsequent epitaxial growth, Due to the different growth rates of different substrate materials, steps are formed to provide alignment for subsequent processes.

[0014] The principle of the method of the present invention lies in that it is difficult to grow on the protective layer or the growth rate is significantly different from that of the substrate layer (generally the substrate layer is silicon) during epitaxial growth. For the sake of process simplicity, the protective layer can be SiO 2 , SiN or SiON, or SiC, generally an inorganic compound between Si, C, 0, and N, and other materials with the same characteristics can also be used. It is only necessary to ensure that the hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com