Device for testing gas cylinder by using computer control moving burette jacket method

A technology of computer control and testing equipment, which is applied in the direction of measuring equipment, using fluid equipment, and applying stable tension/pressure to test the strength of materials, etc. It can solve the problem that the weighing method is easily disturbed by external conditions, rising negative pressure, errors, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

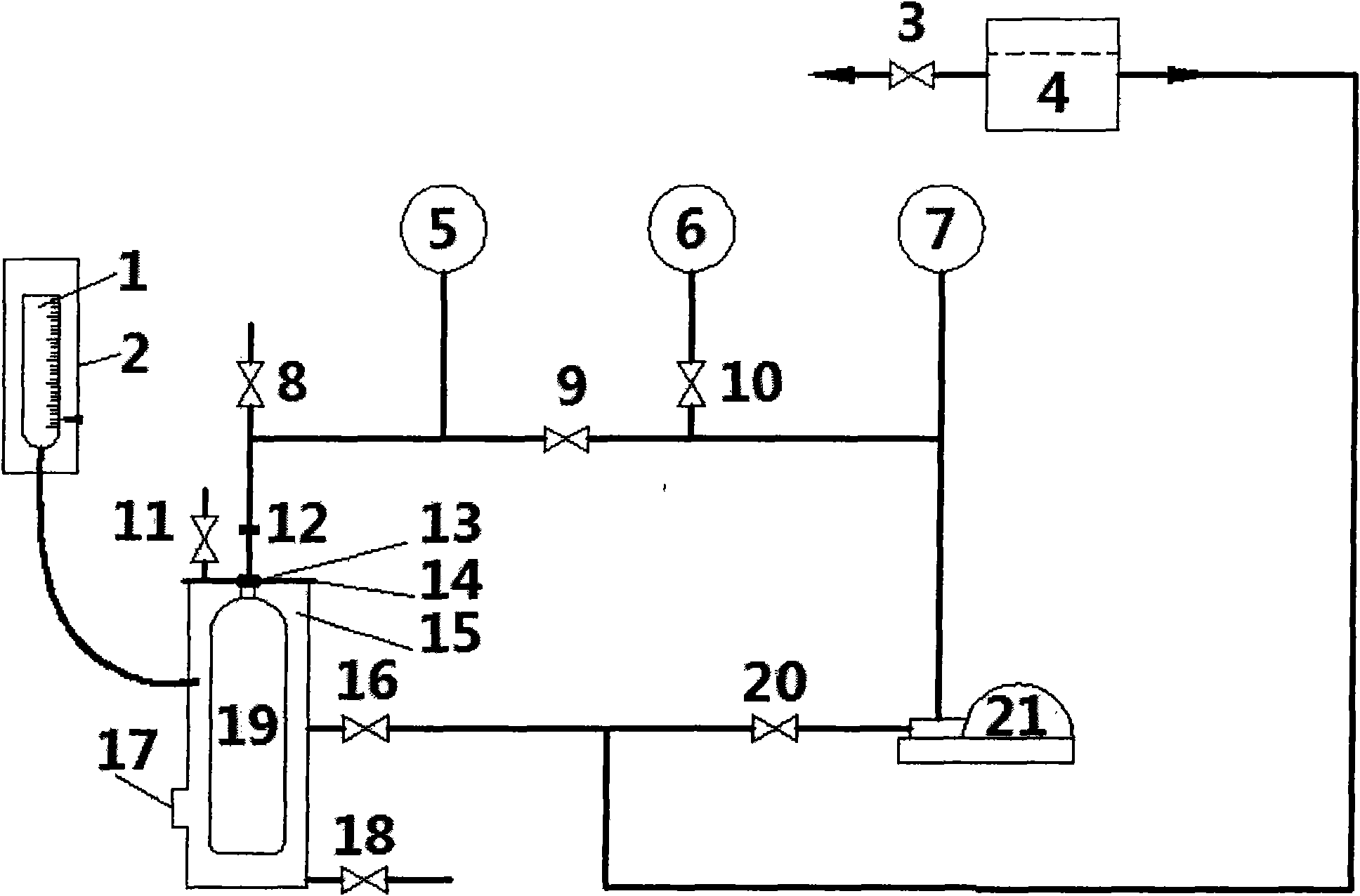

[0030] specific implementation plan

[0031] 1) Record the relevant data of the bottle to be tested.

[0032] 2) Install the test bottle

[0033] 3) Exhaust

[0034] Open the valves 16 and 11 to inject test water into the water jacket 15, and close the valve 11 after the air in the water jacket is exhausted A , close valve 16 when the water surface in the measuring tube is aligned with the "level line" of the bracket; open valves 8 and 9, start hydraulic pump 21, stop hydraulic pump 21 after exhausting the air in the pressure-bearing pipeline, and close valve 8 .

[0035] 4) While the internal liquid level position of the pressure measuring tube 1 changes, the height position of the active measuring tube is adjusted when the digital control is driven, so that the absolute position of the internal liquid level remains unchanged

[0036] 5) Stand still

[0037] Automatically read the scale value at the water surface in the measuring tube 1. After standing for 30s, monitor ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com