Vehicle-mounted high-pressure DC steam injection boiler system with three-pass flue gas

A high-pressure direct-flow steam injection boiler technology, which is applied to steam boilers, mining fluids, steam generation, etc., can solve the problems of low combustion efficiency and small evaporation, and achieve the goal of increasing the temperature of the inlet working fluid, increasing the evaporation, and avoiding condensation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

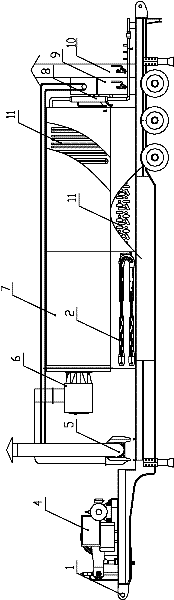

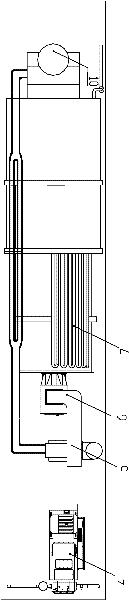

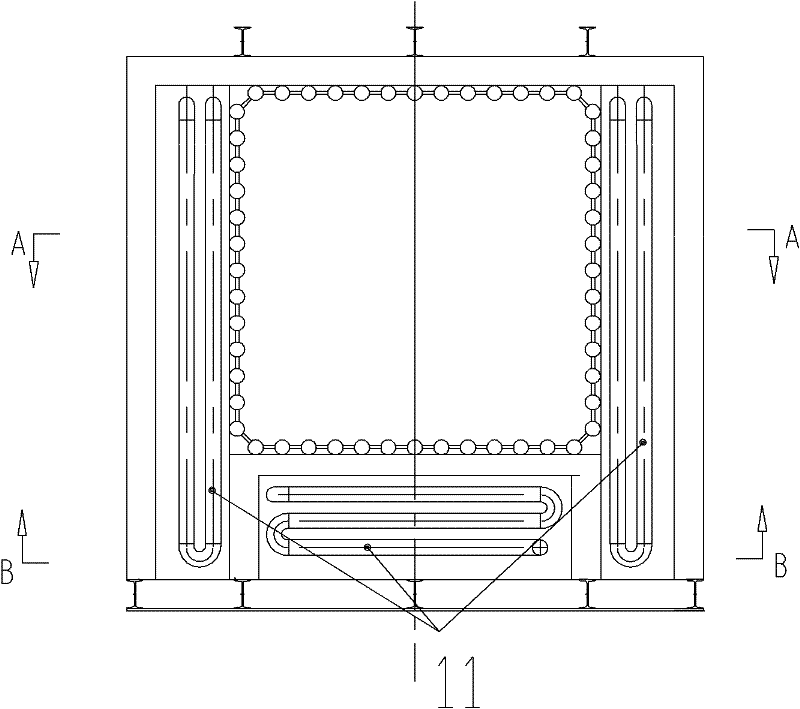

[0032] refer to figure 1 , figure 2 , a vehicle-mounted flue gas three-return high-pressure direct-flow steam injection boiler system of the present invention mainly includes a trailer 1, a casing water-water heat exchanger 2, a convection section 3, and sequentially arranged on the trailer along the length direction of the trailer. High-pressure feed water pump 4, combustion-supporting fan 5, burner 6, radiation section 7, steam-water separator 8, air preheater 9 and chimney 10. Wherein, the high-pressure feed water pump 4 is a high-pressure plunger pump, the cross section of the radiation section 7 is square, and the casing water-water heat exchanger 2 is arranged outside the lower side of the first half of the radiation section. The convection section 3 includes left, right, and lower rectangular flue gas passages and convection tube bundles 11 respectively placed in the above three rectangular flue gas passages. The left, right, and lower rectangular flue gas passages ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com