Mine goaf tailing-filled concrete enclosing wall

A goaf and closed wall technology, applied in the fields of backfill, mining equipment, earthwork drilling, etc., can solve the problems of inability to meet the height difference, low strength of the water filter wall, etc., and achieve the elimination of hidden safety hazards, high dynamic water pressure, Ensure the effect of normal production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

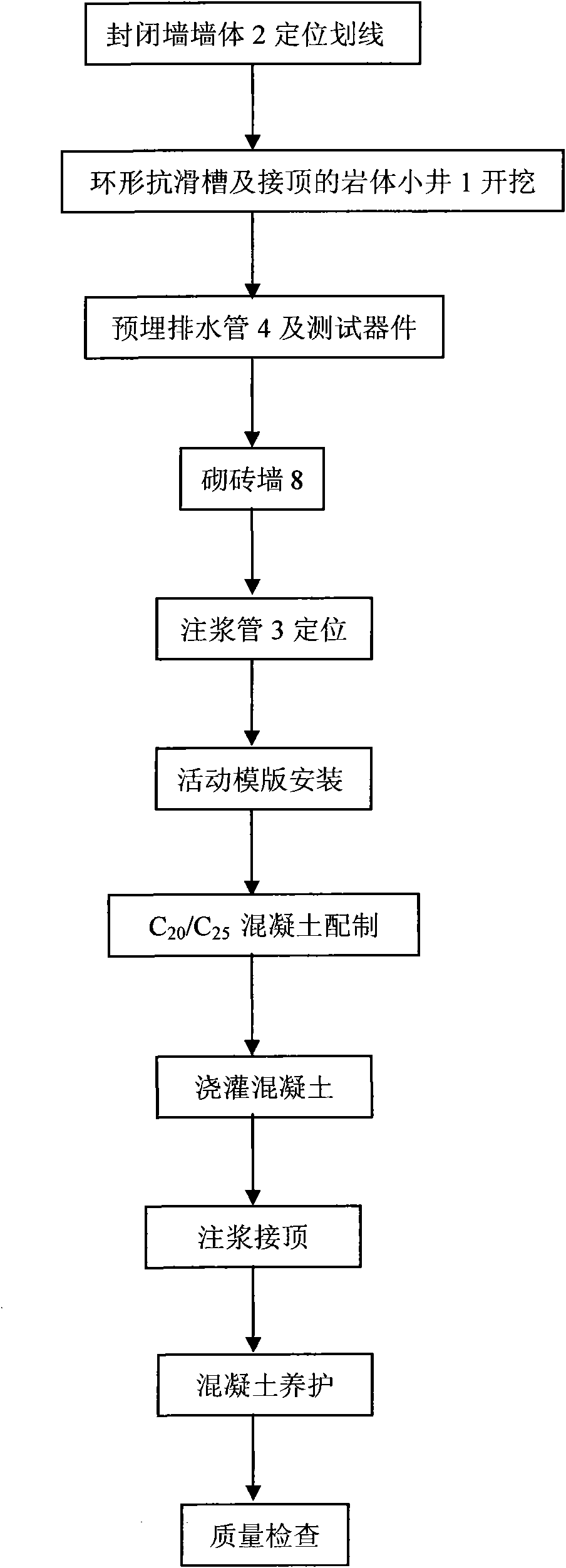

[0022] In order to further describe the present invention, a concrete closure wall for filling tailings in mine goaf according to the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

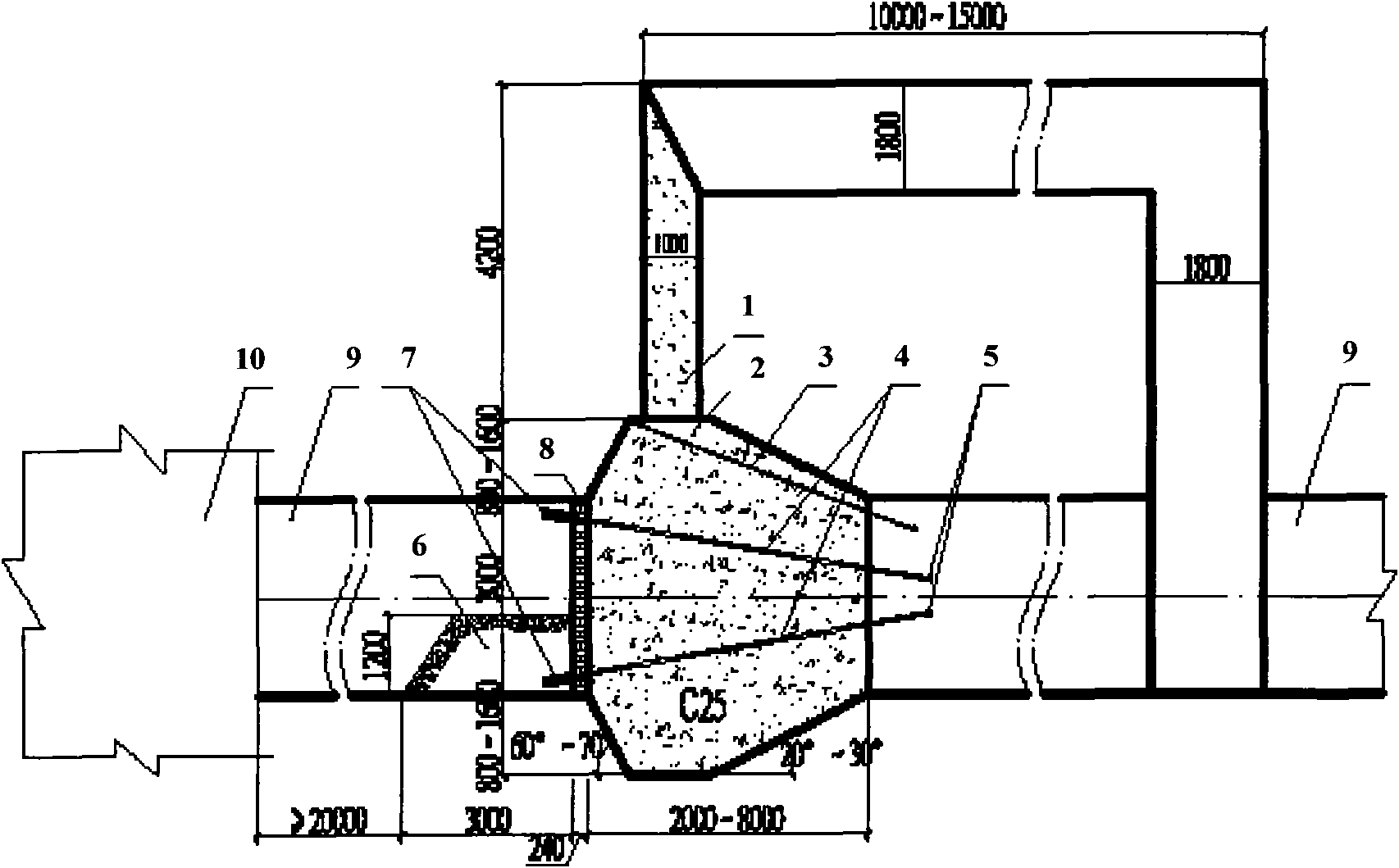

[0023] figure 1 Shown is a longitudinal projection of a concrete closure wall filled with tailings in a mine goaf according to the present invention.

[0024] figure 2 Shown is a horizontal projection of a concrete closure wall filled with tailings in a mine goaf according to the present invention

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh size | aaaaa | aaaaa |

| Equivalent aperture | aaaaa | aaaaa |

| Mesh size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com