Construction method for releasing strong restraint stress of steel connecting rods of oblique and stiffened concrete structures

A technology of concrete structure and construction method, which is applied in the direction of building structure, construction material processing, construction, etc., can solve problems such as strong restraint stress, influence of engineering structure construction progress, cracks in steel concrete columns, etc., to speed up construction progress, Significant economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

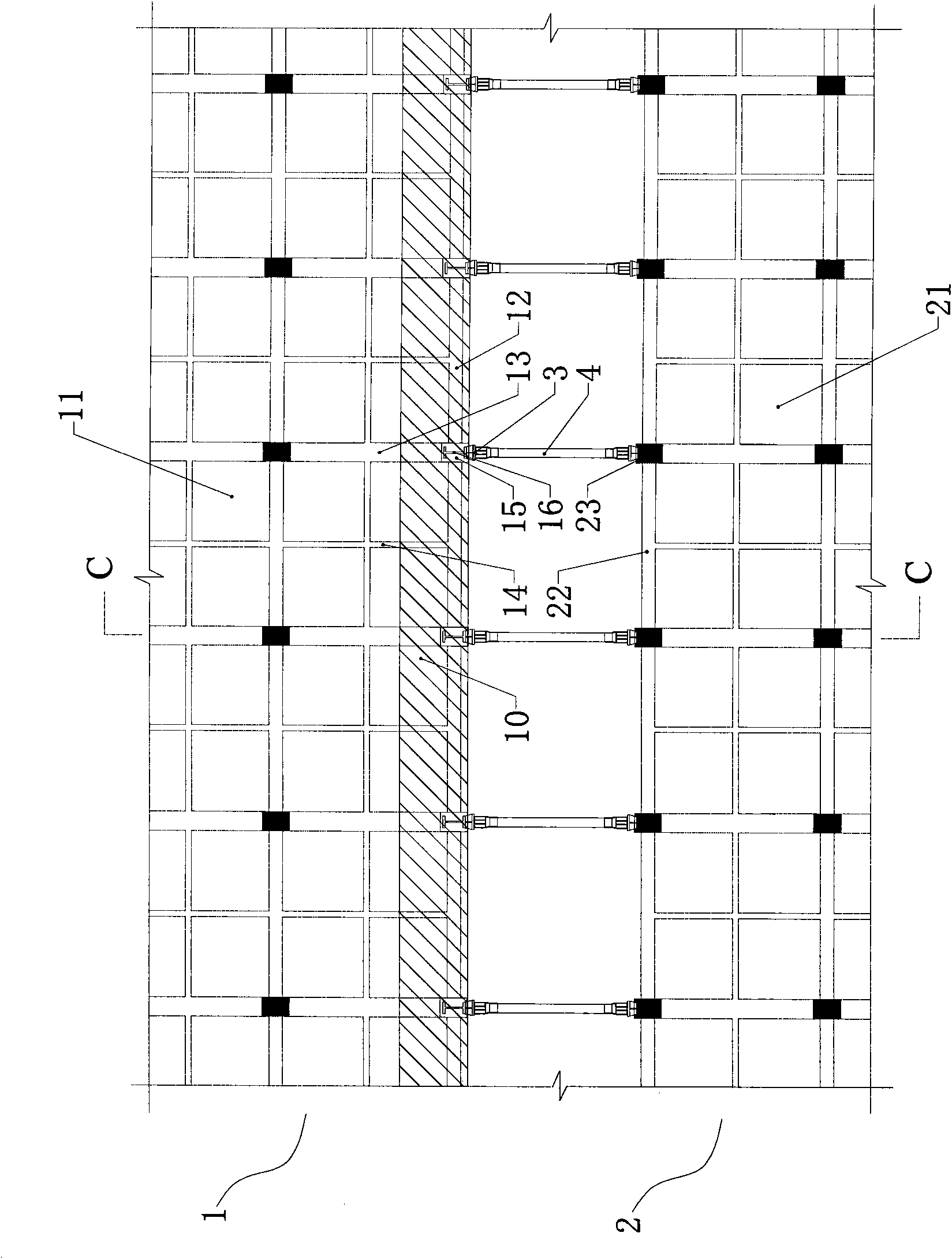

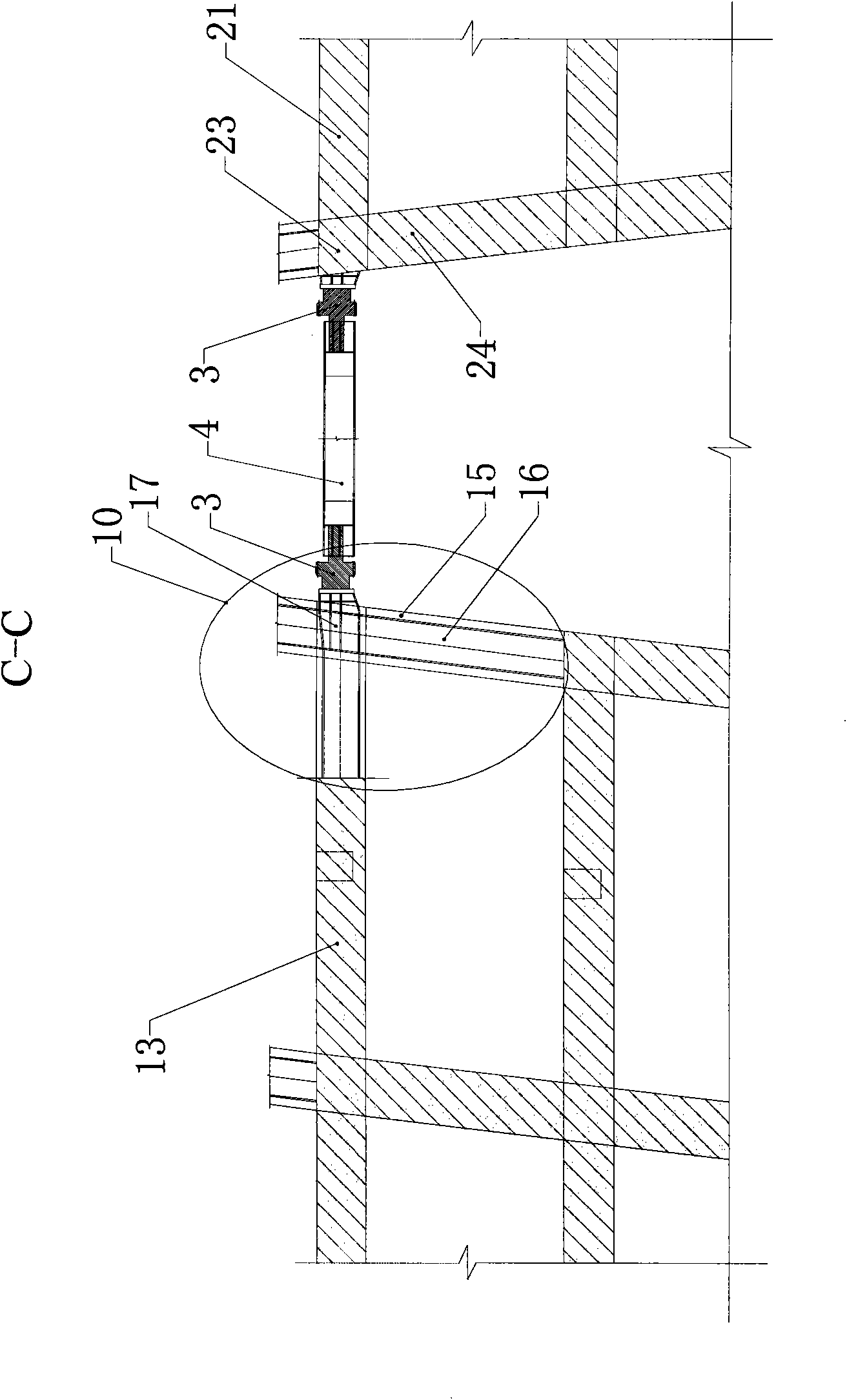

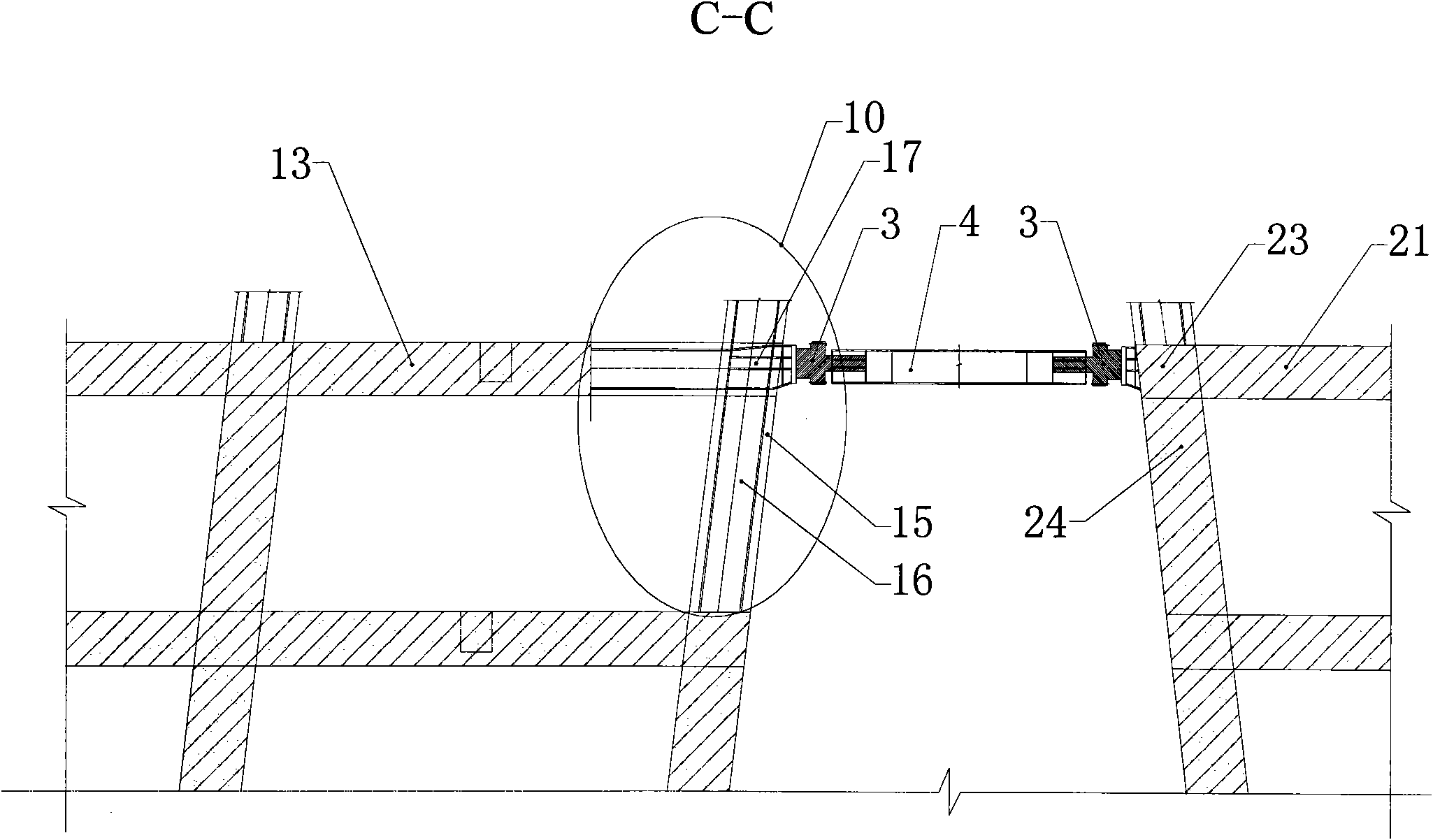

[0019] Such as figure 1 and figure 2 As shown, Building A 1 and Building B 2 are two buildings with inclined stiffened concrete structures, and steel connecting rods need to be installed between the upper nth floors of the two inclined stiffened concrete structures. The specific construction method is as follows:

[0020] A, first carry out concrete pouring construction to the floor 21 and beams (comprising main beams, secondary beams and side beams 22) of the nth floor of B building 2. On the nth floor of Building A, a post-casting section area 10 is set up and concrete pouring construction will not be carried out temporarily. The post-casting section area 3 includes a stiff column 15 on the n-1st floor connected to one end of the steel connecting rod, and an edge beam 12 on the nth floor. , a floor 11 with a third span inward from the edge beam 12 on the nth floor, a main beam 13 and a secondary beam 14 that are in the floor with a third span and connected to the edge bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com