Integrated side-push box filler

A technology for case packing machine and case blank, which is applied in the field of integrated side-push type case packing machine, can solve the problems of high failure rate, loose equipment swing, poor operation stability, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

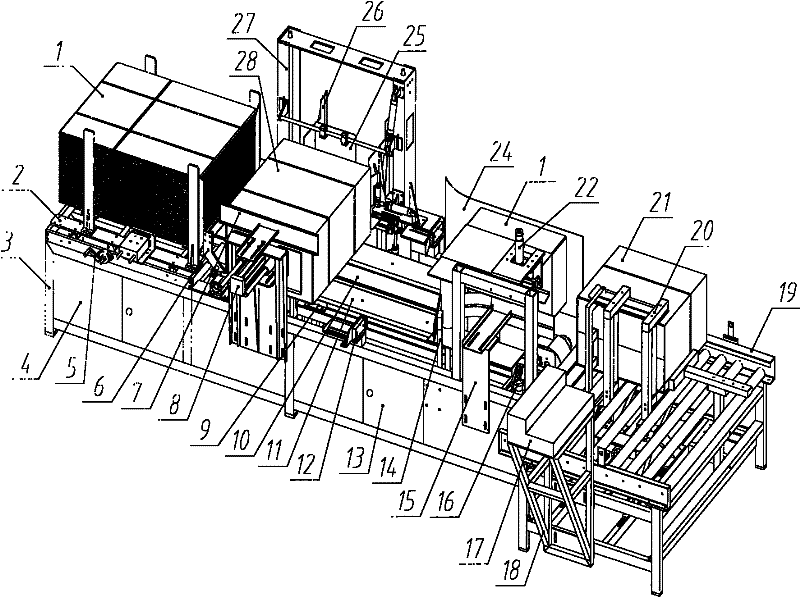

[0023] The present invention is described in detail below in conjunction with accompanying drawing:

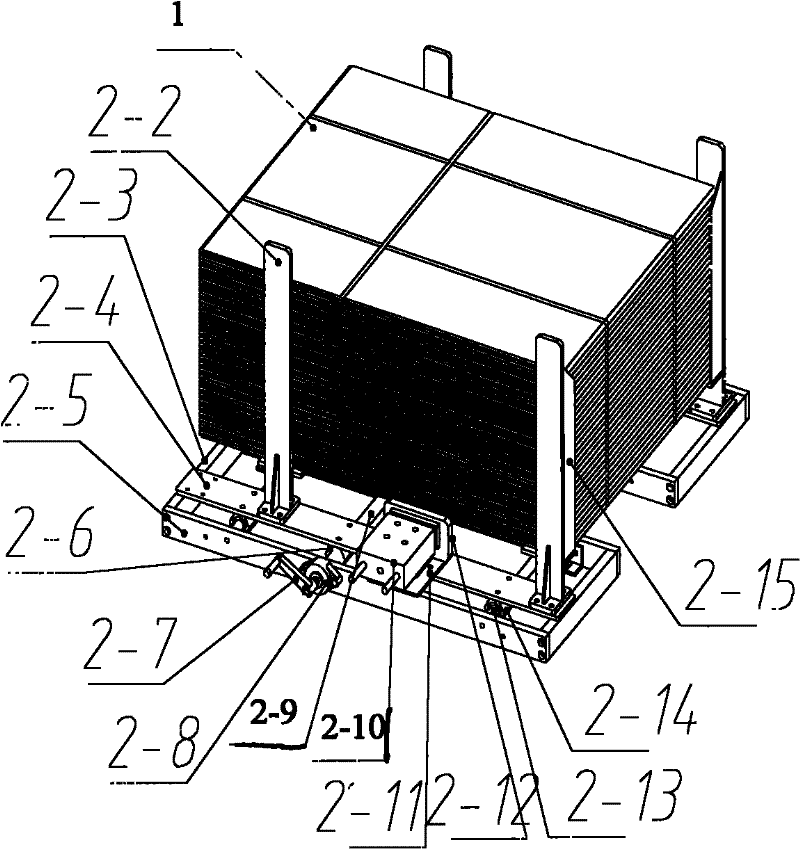

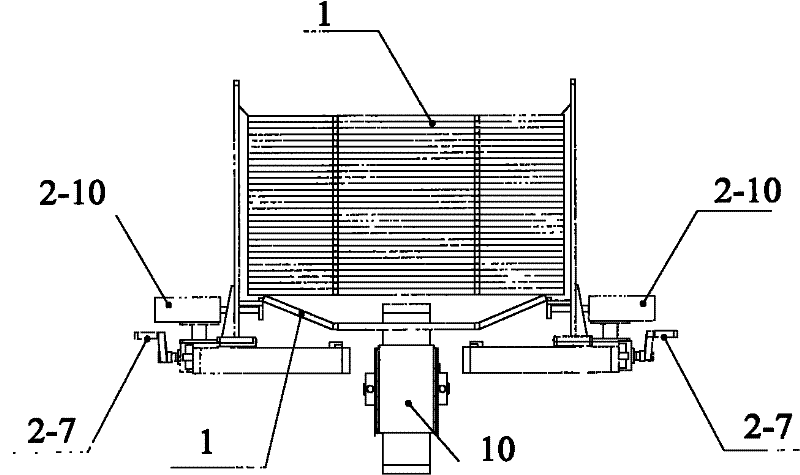

[0024] Such as figure 1 As shown, the present invention includes a box blank supply part 2, a frame 3, an electric control cabinet 4, an air source cabinet 13, an unpacking part, a box delivery chain plate 10, a supporting box plate 11, a carton folding hammer assembly 14, three Set of carton folding components (15, 16, 22), box turning parts, laminated parts 27, box blank limit block 12 and baffle plate 24, the described box opening parts are composed of side suction box assembly 6, box baffle plate 7 , retaining bag cylinder 8, bottom suction box assembly 9, box opening plate 25, and the described box turning parts are made up of bidding assembly 17, bidding frame 18, box turning roller assembly 19, box turning device 20, and bidding assembly 17 is installed on the bidding frame, and the bidding frame 18 and box turning device 20 are installed on the frame 3 respectively, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com