Three-part five-dimensional digital pulse condition sensor

A technology of pulse condition and sensing head, which is applied in the fields of sensors, medical science, vaccination and ovulation diagnosis, etc. It can solve the problems of flexible finger pulse cutting which is difficult to simulate and the synchronous acquisition and digital output of three-dimensional or more pulse condition information, and achieves a broad market application prospect , the effect of important economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The implementation of the present invention will be further specifically described below with reference to the accompanying drawings and specific embodiments.

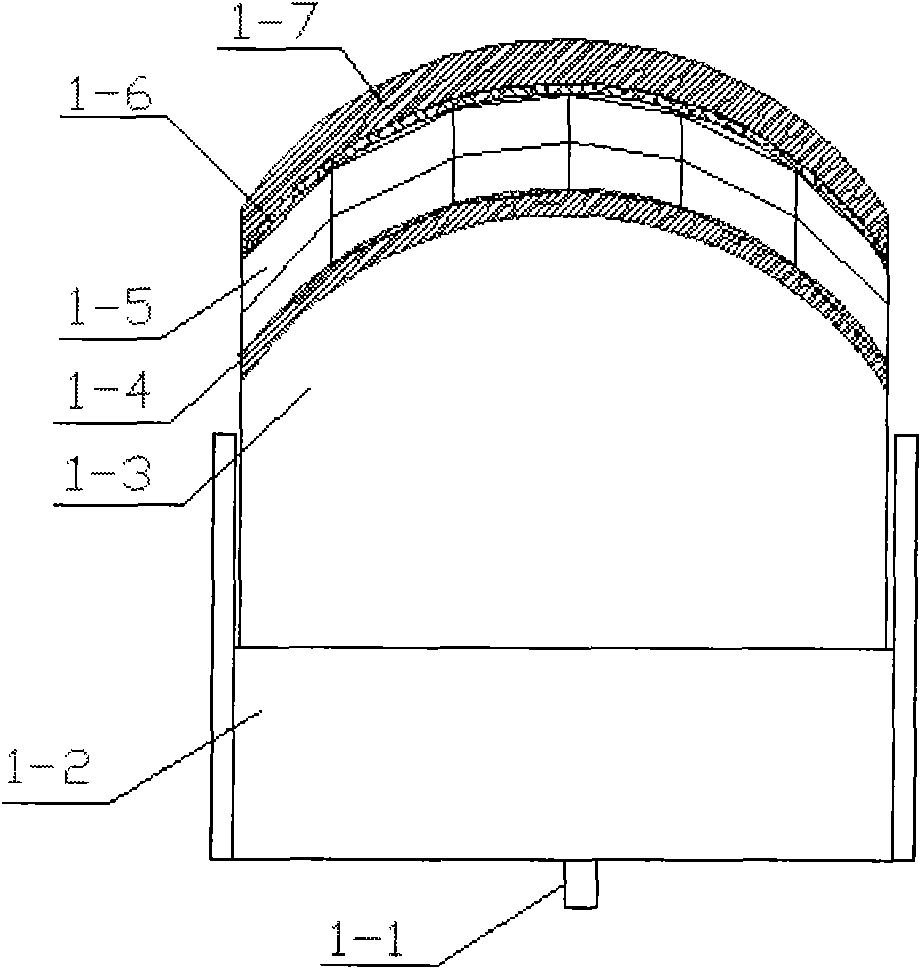

[0012] like figure 1 Shown is a schematic diagram of the sensing head of the present invention. The sensing head is composed of seven parts: hydraulic cylinder nozzle (1-1), hydraulic cylinder (1-2), piston (1-3), metal sheet (1-4), miniature sensing element (1- 5), composed of a flexible circuit board (1-6) and a flexible packaging film layer (1-7). The nozzle of the hydraulic cylinder and the hydraulic cylinder are made of hard materials. The nozzle of the hydraulic cylinder is connected with the hydraulic drive device to receive hydraulic control information; the inside of the hydraulic cylinder is smooth, which is convenient for the liquid seal and the free movement of the piston; the metal sheet is made of good conductive material , and have a good electrical connection with the miniature sensing element,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com