Active extract containing trilobatin and application thereof

A technology of extract and trilobatin, applied in the field of active extract containing trilobatin and its application, can solve the problems of simplicity, low cost, no process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

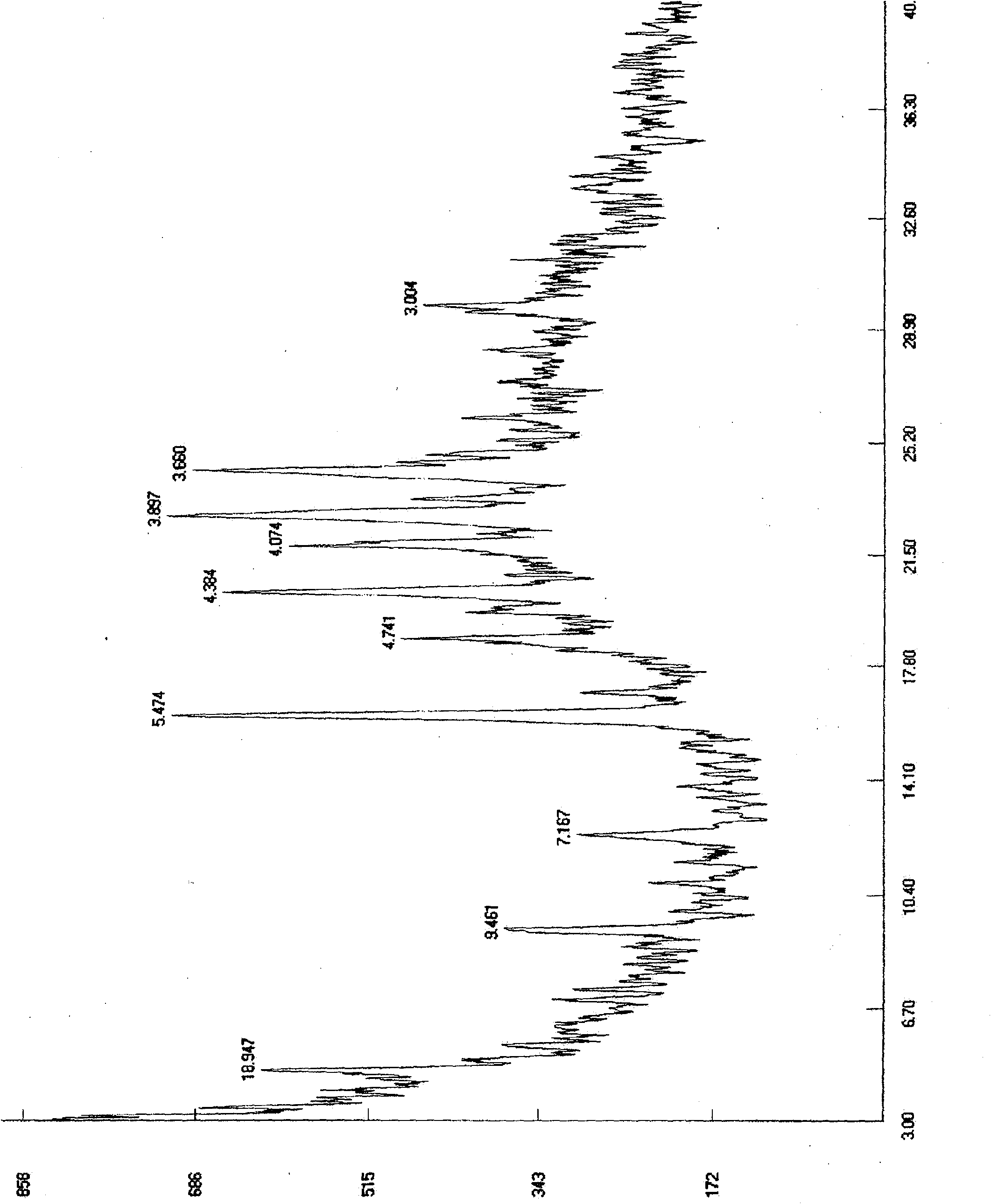

[0050] Embodiment 1 macroporous resin refining trilobatin

[0051] Add 8 times the amount of 70% ethanol aqueous solution to the tender leaves of Cloveria fringa, soak for 2 hours, heat to reflux state, and reflux for 1 hour, filter; add 6 times the amount of 70% ethanol aqueous solution to the filter residue and heat to reflux state And reflux for 1 hour, filter; repeat this process 1 time. The filtrates were combined, concentrated under reduced pressure to recover ethanol, and trilobatin extract was obtained.

[0052] Put 30g of trilobatin dry extract in 100ml of distilled water, heat to 80°C and keep stirring to completely dissolve the trilobatin, then filter while hot to obtain a brownish-brown clear solution, let it stand and cool to 20-40°C, and dissolve the solution Add it to the head of medium-polarity macroporous adsorption resin (DM-301), elute with distilled water to remove some water-soluble impurities and pigments, then elute with 20%-50% ethanol aqueous solution...

Embodiment 2

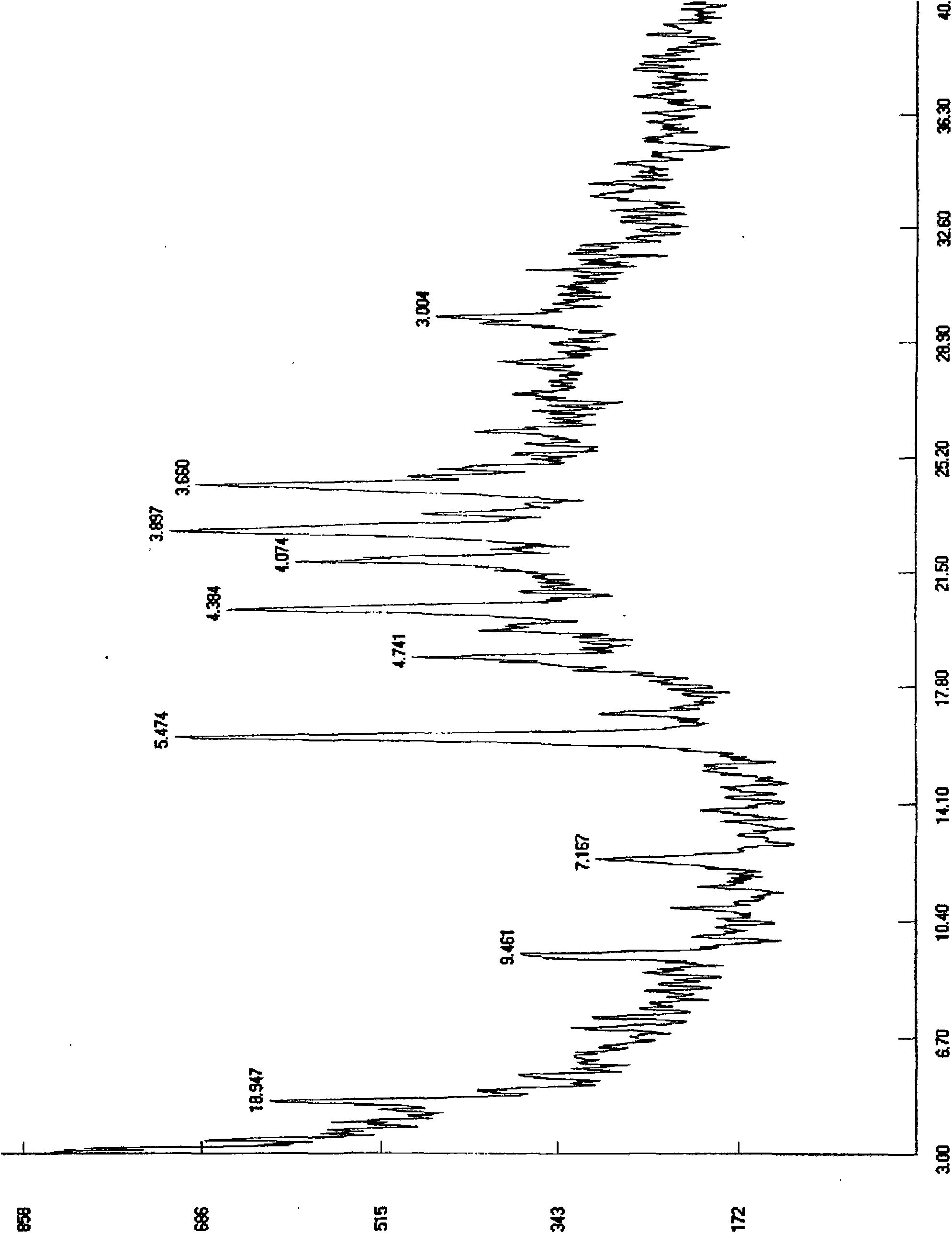

[0058] Example 2 Polyamide Refined Trilobatin

[0059] Add 10 times the amount of 80% ethanol aqueous solution to the young leaves of Cloveria fringa, soak for 30 minutes, heat to reflux state, and reflux for 1 hour, filter; add 5 times the amount of 80% ethanol aqueous solution to the filter residue, heat to reflux state and Reflux for 1 hour and filter; this process is repeated once. Combine the filtrates, recover ethanol under normal pressure, and concentrate to obtain trilobatin extract.

[0060] Put 30g of trilobatin dry extract in 100ml of distilled water, heat to 80°C and keep stirring to completely dissolve the trilobatin, then filter while hot to obtain a brownish-brown clear solution, let it stand and cool to 20-40°C, and dissolve the solution Add to the head of polyamide, elute with distilled water to remove some water-soluble impurities and pigments, then elute with 20%-40% ethanol aqueous solution, TLC detection, collect the eluate at the end, concentrate and fil...

Embodiment 3

[0062] Make tablet of the present invention by following formula: (all content used is weight percent composition)

[0063] Active extract with 70% trilobatin 54.5%

[0064] Microcrystalline Cellulose 42.0%

[0065] PVP-k30 1.0%

[0066] Magnesium Stearate 0.5%

[0067] Sodium Carboxymethyl Starch 2.0%

[0068] Mix trelobatin extract, microcrystalline cellulose, and part of carboxymethyl starch sodium, add PVP-k30 ethanol solution to make soft material, granulate through a 20-mesh sieve, granulate after air-drying at 60°C, add carboxymethyl starch Sodium methyl starch and magnesium stearate are mixed evenly and pressed into tablets.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com