Chicken bone protein zymolyte and chicken essence substrate prepared by same

A technology of proteolysis and chicken essence, which is applied in food preparation, food science, application, etc., can solve the problems of ineffective utilization, limited source of raw materials, and cost reduction, and achieve the effects of low destructive power, realistic chicken aroma, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

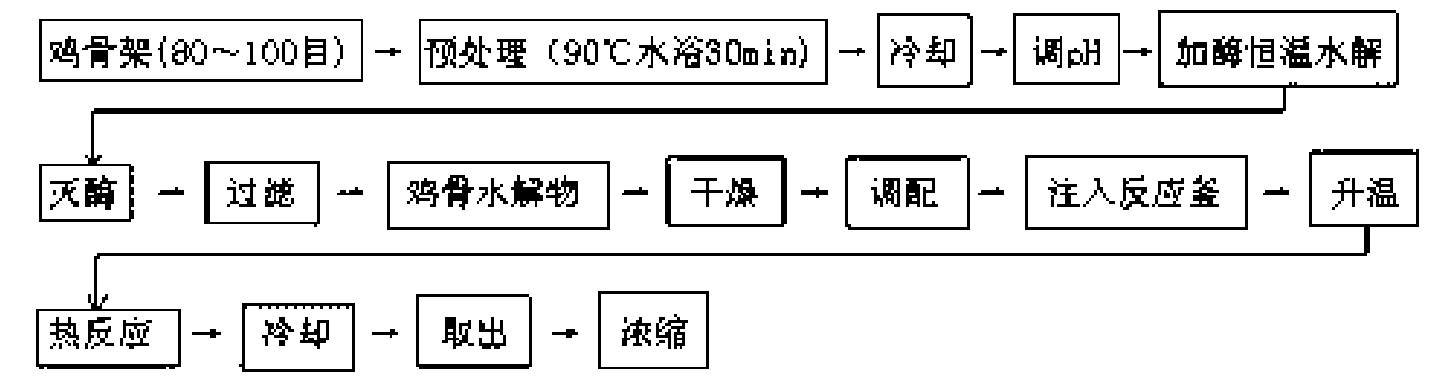

Image

Examples

preparation example Construction

[0031] The preparation steps of chicken essence base material comprise:

[0032] (1) Cooking of chicken oil: take fresh chicken subcutaneous fat, and boil light yellow chicken oil at 90°C to 100°C;

[0033] (2) Mixing and deployment: according to the ratio, chicken bone protein enzymatic hydrolyzate, plant hydrolyzed protein, yeast extract, glucose, xylose, thiamine, chicken oil, L-cysteine hydrochloride, Propylene glycol and water are mixed, and the pH value is adjusted between 5 and 6;

[0034] (3) Maillard reaction: Pour the mixed solution of step (2) into a high-pressure reactor, raise the temperature to 100-120°C, react for 60-100 minutes and then quickly cool down to 50°C, open the kettle, and take out the reactant ;

[0035] (4) Concentration: the reactant is vacuum concentrated to a concentration of 35wt%-45wt% to obtain the chicken essence base material.

[0036] This product has a strong chicken aroma, full of meat, and outstanding chicken fat aroma, not greasy,...

Embodiment 1

[0040] (1) Raw material pretreatment: superfinely pulverize chicken bones to make 80-mesh bone paste, add water to prepare chicken bone paste suspension with a concentration of 25%, and heat at 90°C for 30 minutes;

[0041] (2) Enzymolysis: control the reaction temperature at 50°C, adjust the pH to 8.5, add pancreatin and Flavourzyme compound flavor protease successively, and the enzyme dosage is 0.98wt% and 2.6wt% of the chicken bone raw material (fresh weight) respectively, reaction 2 Hour.

[0042] (3) Enzyme inactivation: raise the temperature of the reaction system to 90°C for 10 minutes;

[0043] (4) Filtration: adopt a centrifuge, centrifuge at 4000 rpm for 10 minutes, and collect the supernatant;

[0044] (5) drying: freeze-drying to light yellow powder;

[0045] (6) Chicken oil cooking: take an appropriate amount of fresh chicken subcutaneous fat, and boil light yellow chicken oil at 90°C;

[0046] (7) Mixing, deployment: chicken bone protein enzymatic hydrolyzate ...

Embodiment 2

[0050] (1) Raw material pretreatment: superfinely pulverize chicken bones to make 90-mesh bone paste, add water to prepare chicken bone paste suspension, the concentration is 20wt%, and heat at 90°C for 30 minutes;

[0051] (2) Enzymolysis: Control the reaction temperature to 50°C, adjust the pH to 8, add trypsin and Flavourzyme compound flavor protease successively, the enzyme dosage is 0.865wt% and 2.3wt% of the chicken bone raw material (fresh weight), and react for 2 hours .

[0052] (3) Enzyme inactivation: raise the temperature of the reaction system to 90°C for 10 minutes;

[0053] (4) Filtration: adopt a centrifuge, centrifuge at 4000 rpm for 10 minutes, and collect the supernatant;

[0054] (5) drying: spray drying to light yellow powder;

[0055] (6) Chicken oil cooking: take an appropriate amount of fresh chicken subcutaneous fat, and boil light yellow chicken oil at 100°C;

[0056] (7) Mixing and deployment: chicken bone protein enzymatic hydrolyzate (8wt%), plant...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com