Modularized electric unit pump

A single pump, modular technology, used in fuel injection pumps, engine components, machines/engines, etc., can solve the problems of high manufacturing cost of solenoid valve, high manufacturing cost of single pump, high maintenance cost, and reduce production and assembly. cost, improve product consistency, and reduce manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be described in more detail with examples in conjunction with the accompanying drawings:

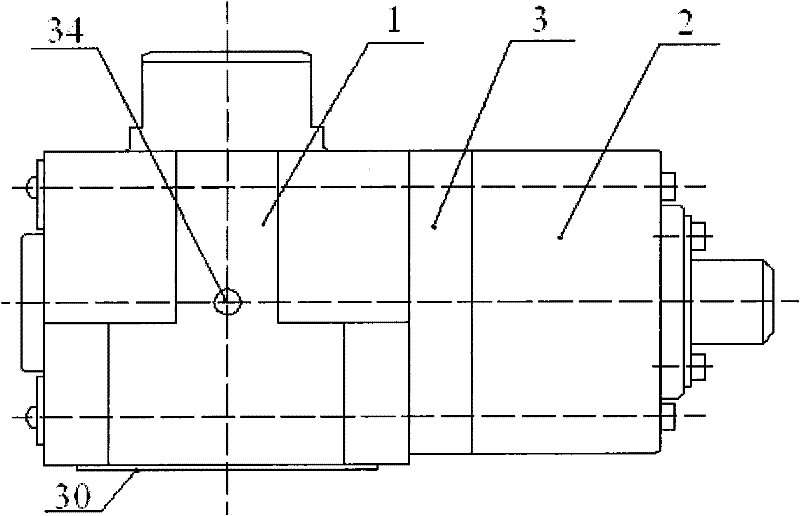

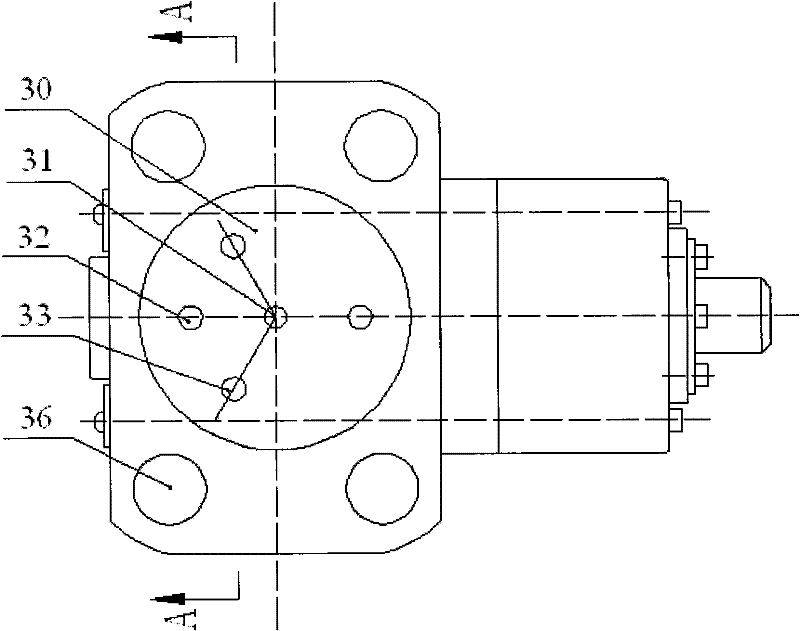

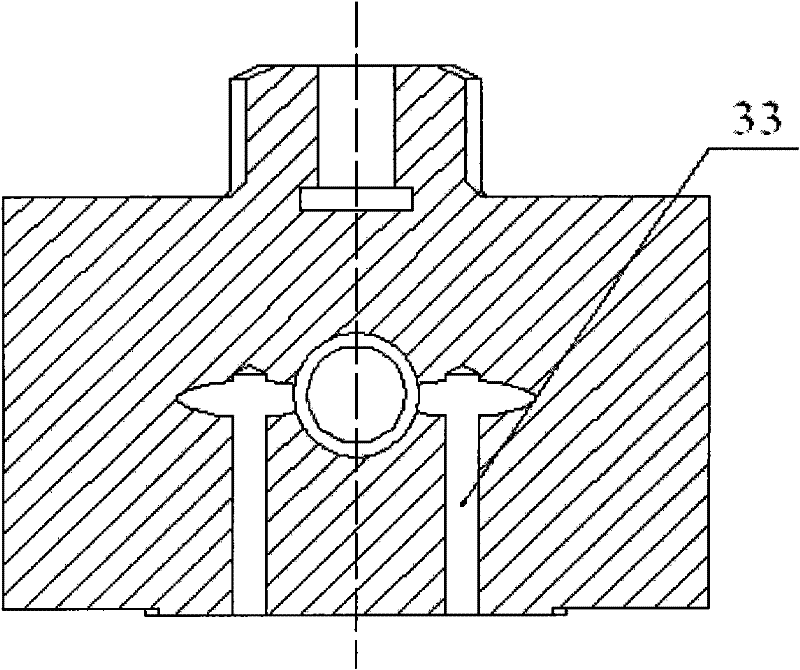

[0028] Combine Figure 1~10 , figure 1 , 2 , 3, 4, and 5 are the schematic diagrams of the solenoid valve of the modular electronically controlled unit pump. The solenoid valve is mainly composed of the valve body 1, the electromagnet housing 2, the electromagnet pad 3, the control valve stem 4, the armature 5, and the return spring stopper. Plate 6, valve stem return spring 7, return spring seat 8, armature fastening screw 9, plug 10, electromagnet 11, solenoid 12, washer 13, long bolt 14, sealing pin 15, and related oil holes and installation positioning holes composition.

[0029] figure 1 The solenoid valve body 1, the solenoid valve housing 2 and the electromagnet pad 3 are shown in the three main components. The electromagnet housing 2 is connected to the valve body 1 and the electromagnet pad 3 by a long bolt 14. A washer 13 is installed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com