Remote control method and device of thin seam working surface coal mining machine

A technology of remote control device and coal mining machine, which is applied in the direction of mining equipment, comprehensive factory control, comprehensive factory control, etc., can solve problems such as unsafety and high labor intensity, and achieve reliable control, accurate positioning of segments, flexible and convenient segments Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

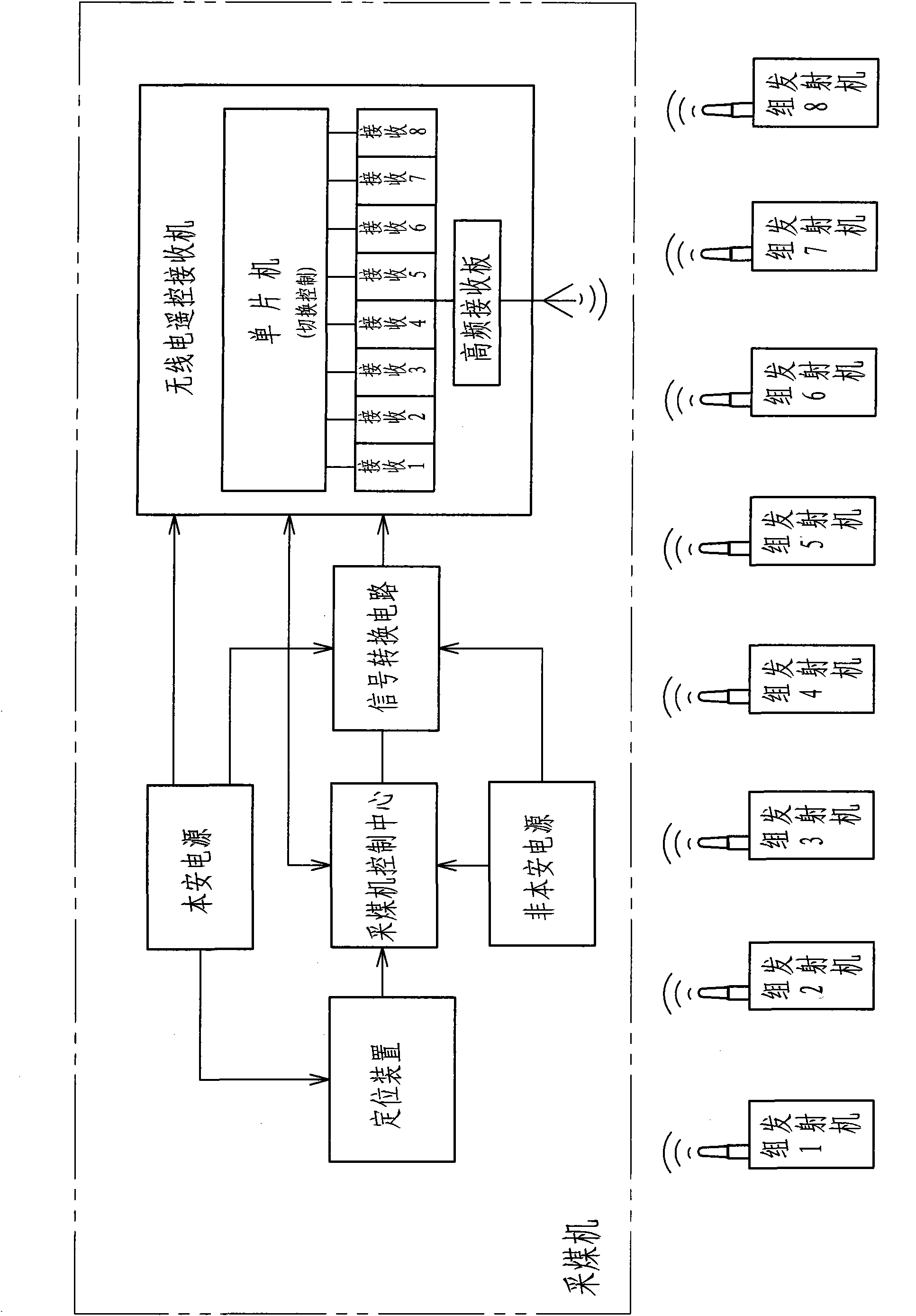

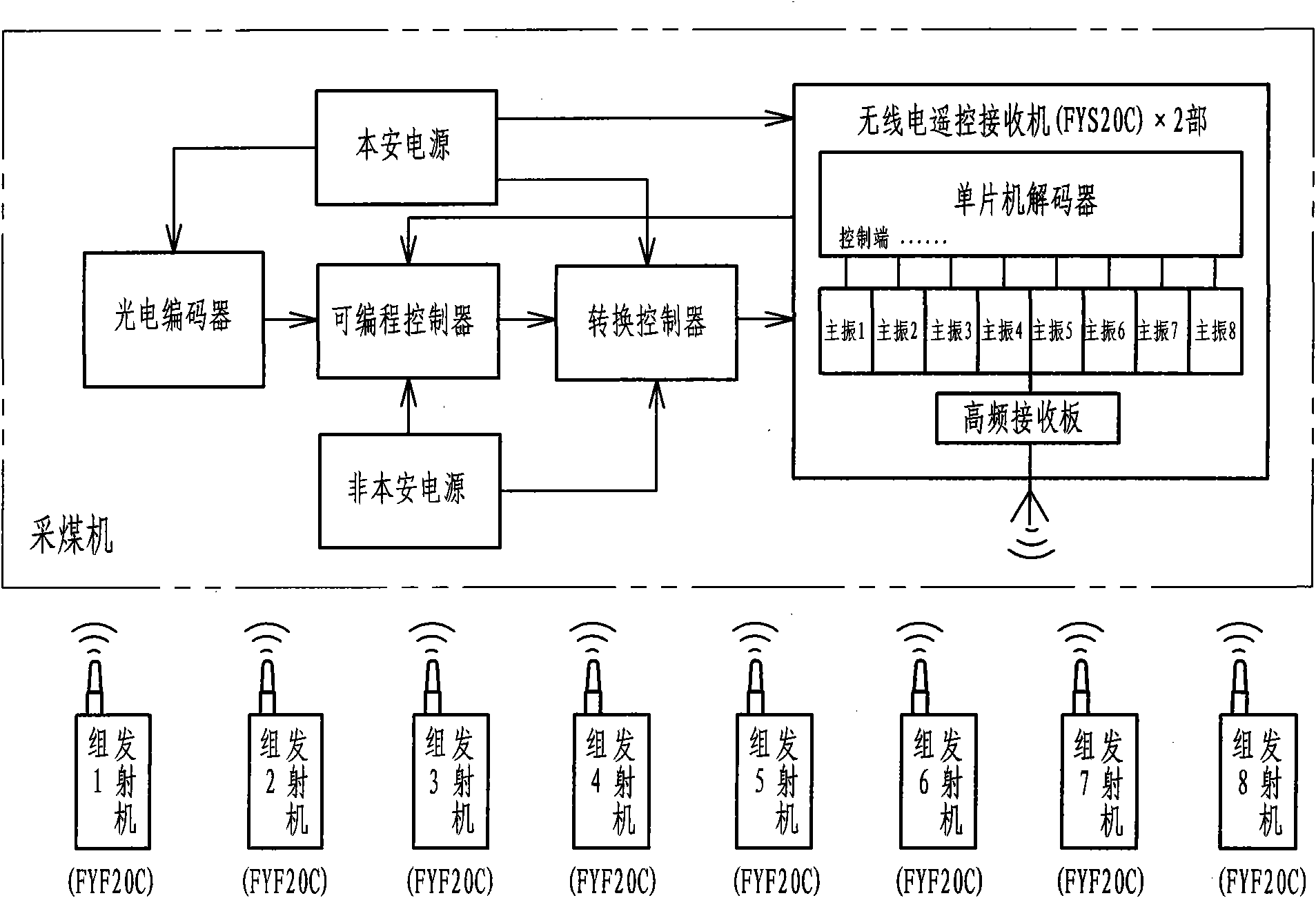

[0034] exist figure 2 Shown in the thin coal seam working face coal mining machine remote control method and device of the present invention, that is, the first implementation of automatic segment remote control. The positioning device adopts a hollow shaft photoelectric encoder, the coal mining machine control center, that is, the main control unit of the coal mining machine, adopts a programmable controller, and the signal conversion circuit adopts a conversion controller.

[0035] The main vibrations 1 to 8 of the radio remote control receiver, that is, the eight main vibration frequencies, are switched by the eight output control terminals of the single-chip microcomputer used as a decoder. The two receivers of the shearer respectively receive the remote control signals of the two transmitters of the same transmitter group, and control the left and right drums of the shearer respectively.

[0036]Radio remote control transmitter groups 1 to 8 have eight carrier frequenci...

Embodiment 2

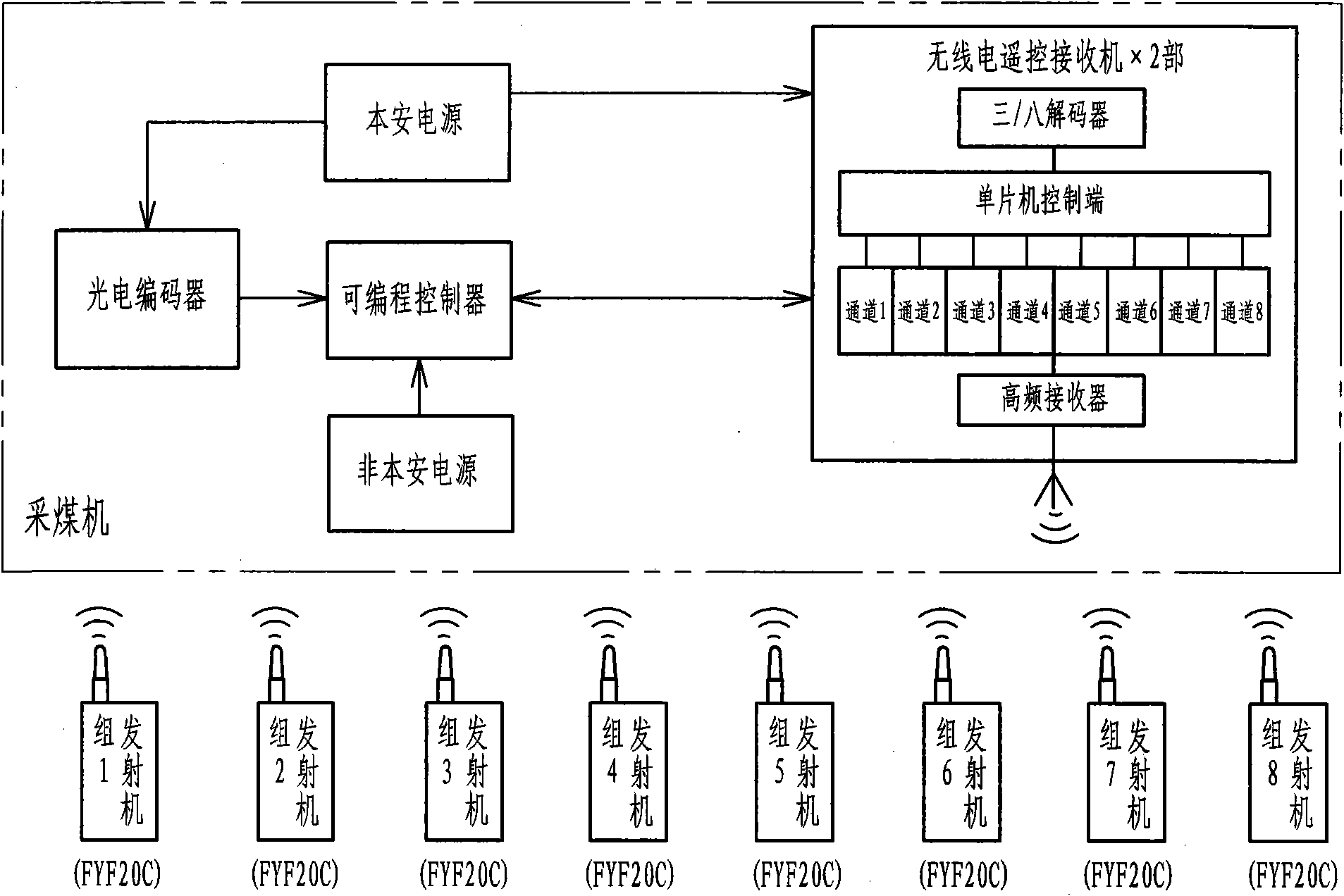

[0047] exist image 3 Another implementation of the automatic segmented remote control of the coal mining machine in the thin coal seam working face is shown in .

[0048] The radio remote control receiver adopts a multi-channel receiver, and realizes segmented remote control by controlling the switching of receiving channels. Although the circuit is not as simple as switching the crystal oscillator and changing the frequency of the main oscillator. But it is also one of the feasible options.

[0049] Switching control of the receiver channel: The segmented coded signals sent by two sets of output terminals of the PLC, three in each group, are transmitted to the radio remote control receiver through the multi-core cable in the form of parallel coded signals, and then passed through the three / The eight-decoder is decoded, and the eight output terminals of the decoder are output to the single-chip microcomputer, and then the eight output terminals of the single-chip microcomp...

Embodiment 3

[0051] exist Figure 5 , 7 Shows the third embodiment of the automatic subsection remote control of the coal mining machine in the thin coal seam working face.

[0052] The coal mining machine control center adopts the industrial control computer, that is, the industrial computer IPC. The positioning device is still based on the hollow shaft photoelectric encoder BM 1 For example, its output terminal A, B terminal and the counting module A of the industrial computer CT The input terminal IN 0 , IN 1 connect. Industrial computer output module A OUT The output terminal R 01 ~R 03 , R 04 ~R 06 Output two sets of segment coded signals respectively. COM 0 The +12V and GND terminals are the DC power supply terminal and the ground terminal. AC220V is the AC power supply terminal of the industrial computer IPC.

[0053] Photoelectric encoder BM 1 The two-phase square wave signal sent by the output terminals A and B passes through the counting module A of the IPC CT The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com