Automatic oiling type emergency hydraulic system of airplane

A hydraulic system and automatic refueling technology, which is applied to the power plant, aircraft parts, mechanical equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

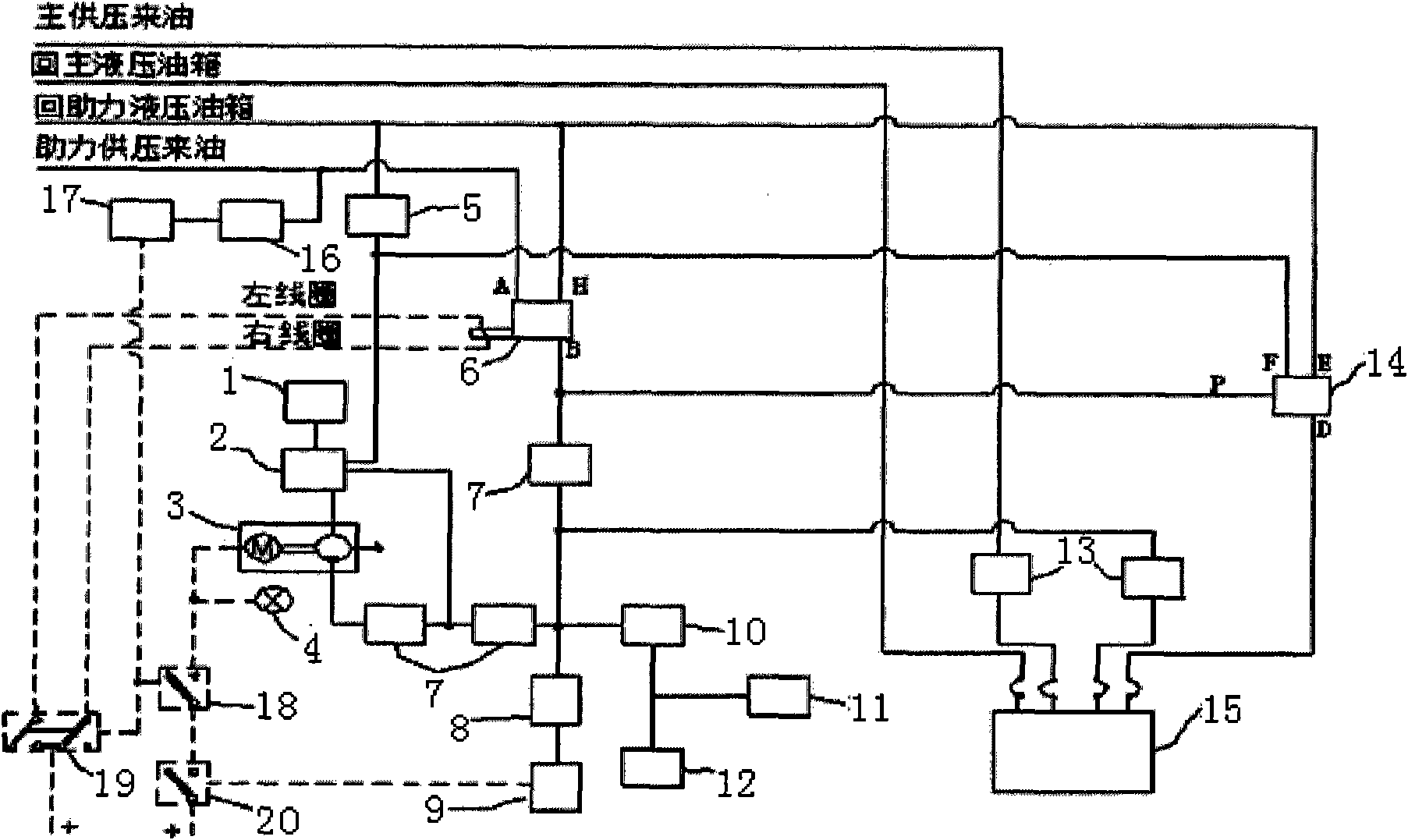

Embodiment 1

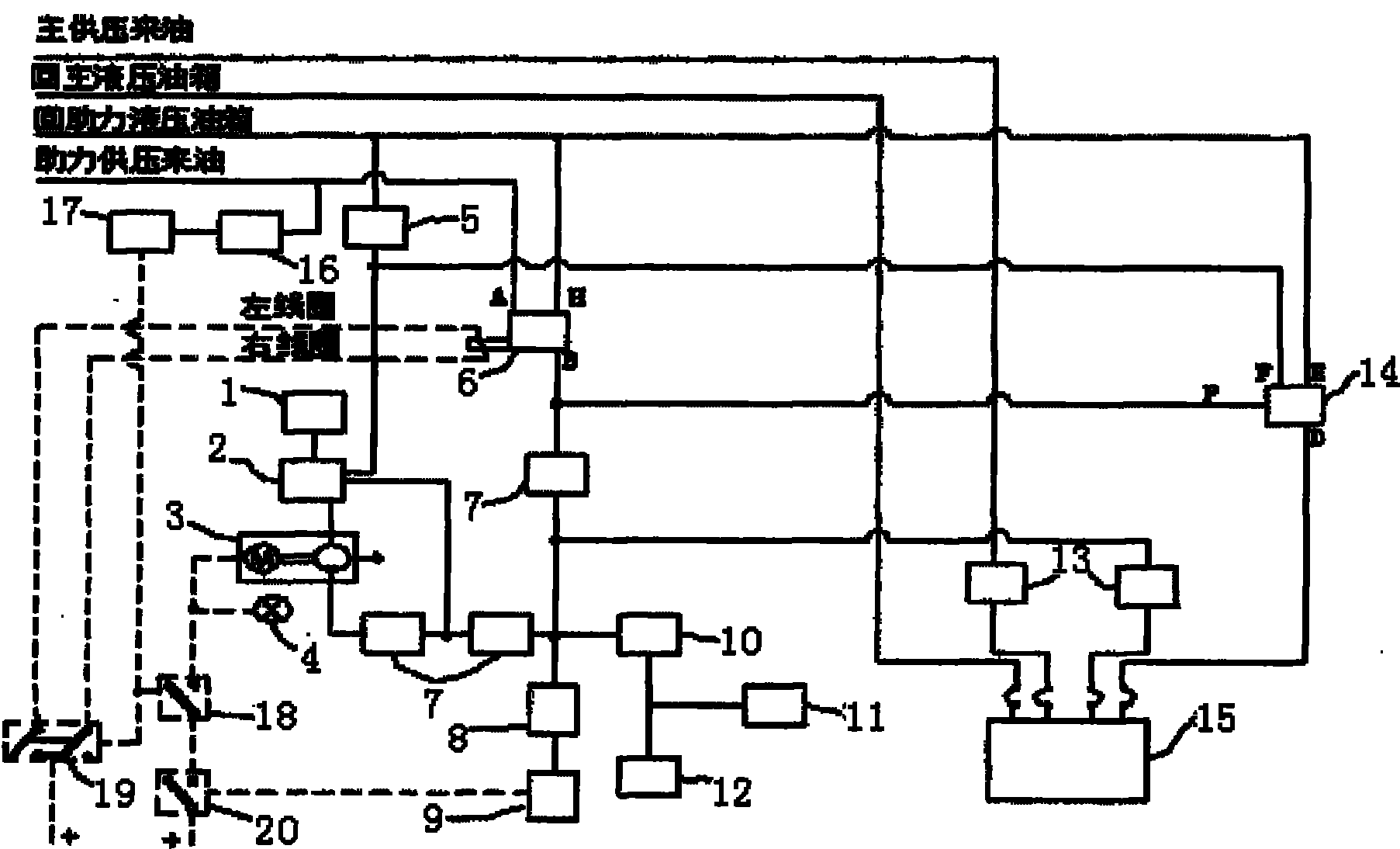

[0016] Embodiment 1: see figure 1 , the aircraft automatic refueling emergency hydraulic system, including hydraulic system and electrical system, in the hydraulic system, one end of the air release valve 1 is connected with the air release port of the emergency fuel tank 2, and the oil outlet of the emergency fuel tank 2 is connected with the emergency electric pump 3, and the emergency fuel tank The oil return port of 2 is connected to the oil return circuit of the emergency system, the oil suction port of the emergency electric pump 3 is connected to the emergency oil tank 2, the oil outlet of the emergency electric pump 3 is connected to the one-way valve 7, and the pipeline of the power-assisted hydraulic oil tank is connected to the emergency oil tank 2 The constant pressure one-way valve 5 is installed in the circuit between them, the A port of the double-position electromagnetic switch 6 is connected with the pressure supply oil circuit of the booster hydraulic system, ...

Embodiment 2

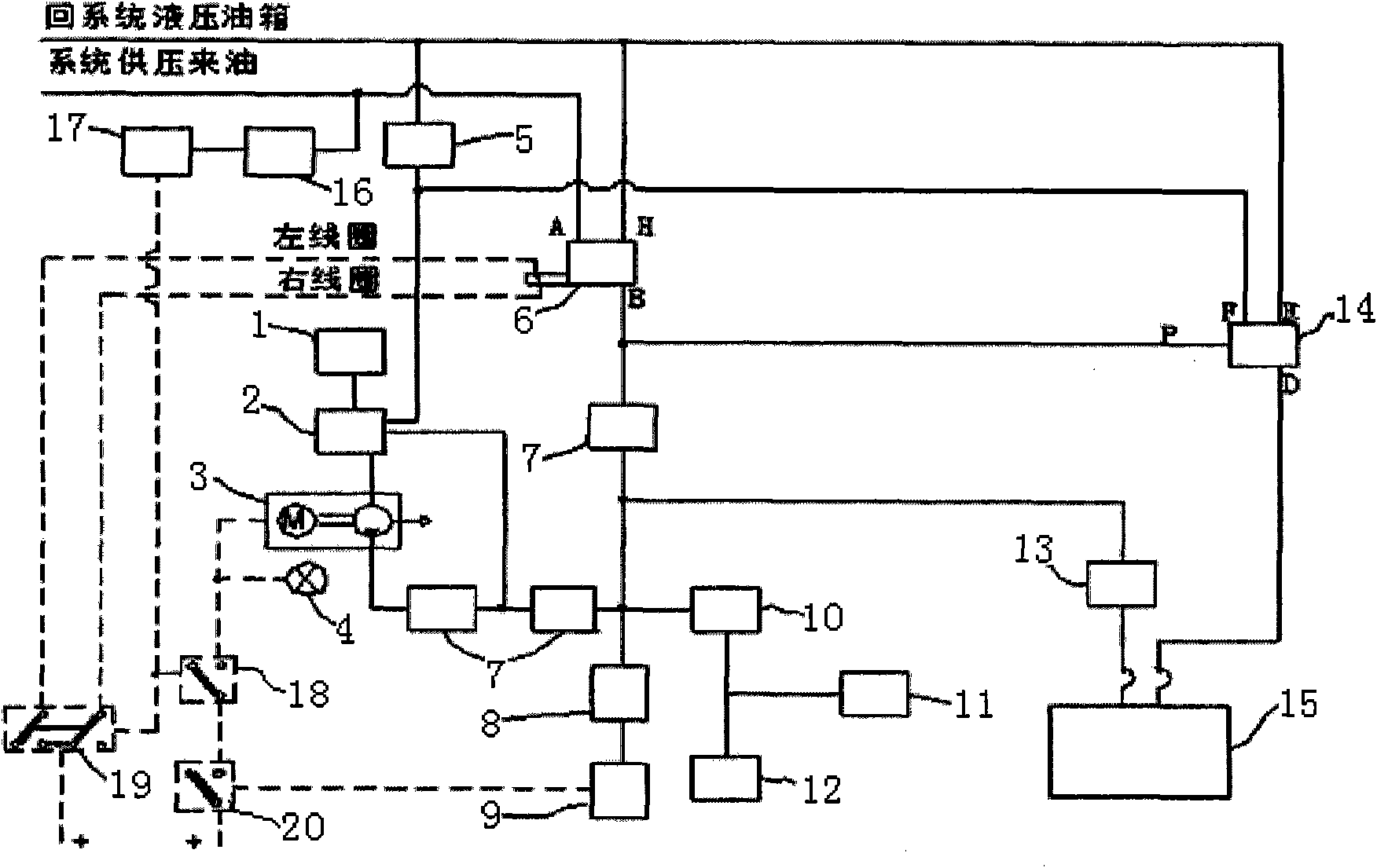

[0030] Example 2: see figure 2 , the system of this embodiment also includes a hydraulic system and an electrical system. The difference between the cross-linking of the hydraulic system and that of Embodiment 1 is that the pressure supply form of the hydraulic system in the non-failure failure mode is a single hydraulic system, and the hydraulic system and the emergency hydraulic system The hydraulic coupling part has only one hydraulic oil filter, and the horizontal tail booster 15 is a single cavity, while the horizontal tail booster in Embodiment 1 is a double-cavity horizontal tail booster; the cross-linking form of the components of the electrical system corresponds to that of Embodiment 1 same.

[0031] The hydraulic system of this embodiment also uses the emergency pressure accumulator 10 to refuel and maintain the pressure of the emergency hydraulic system, and controls the switching between the oil circuits of the two systems through the switching valve 14 . When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com