Vehicle skylight frame and manufacturing method thereof

A technology for a sunroof frame and a manufacturing method, which is applied in the field of vehicle sunroof frames and its manufacturing, can solve problems such as hidden dangers in quality, low pass rate, and cumbersome procedures, and achieve the goals of reducing matching errors, reducing the amount of riveting, and ensuring accuracy and consistency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to better understand the technical solution of the present invention, it will be described in detail below through specific embodiments in conjunction with the accompanying drawings:

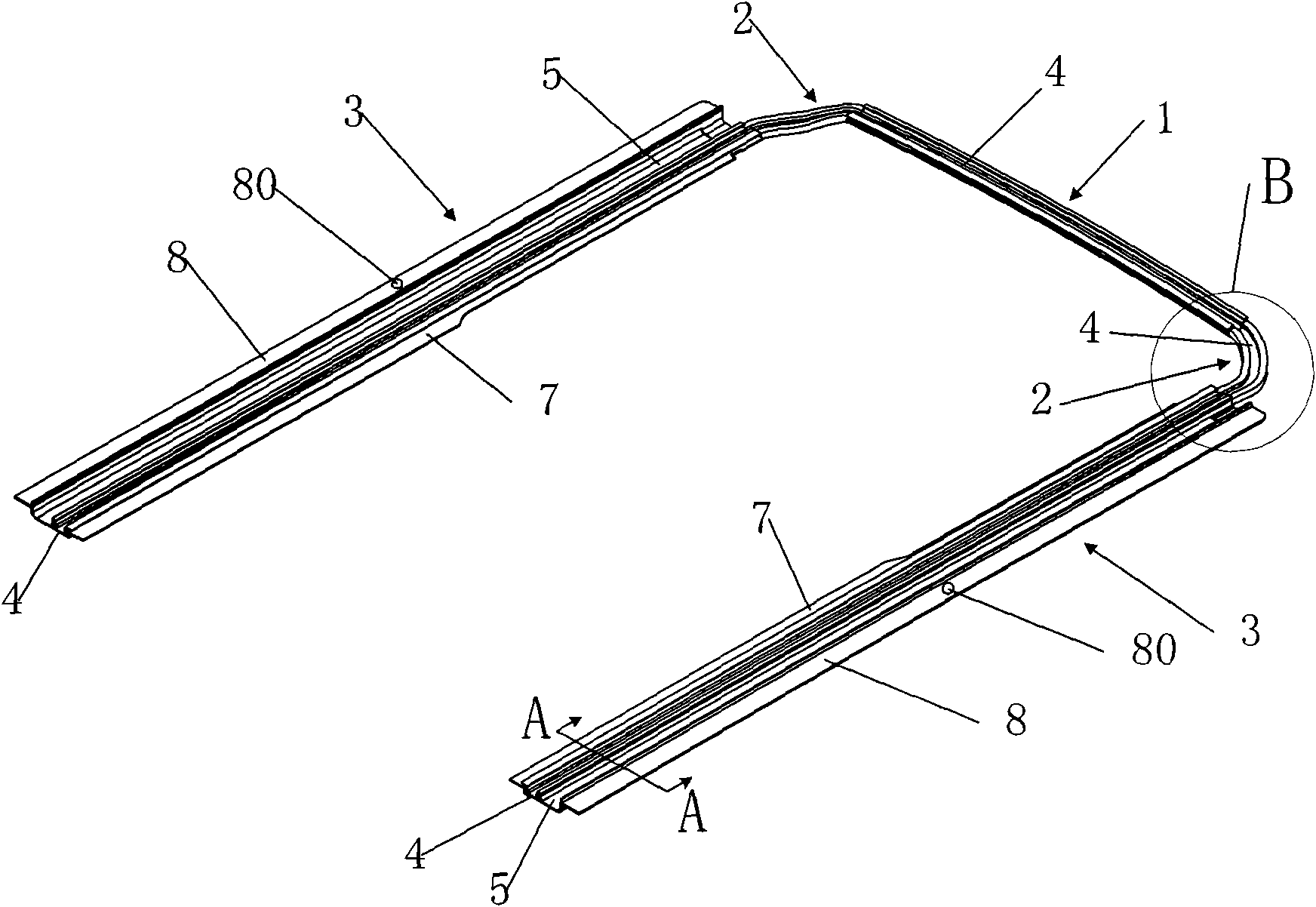

[0031] see figure 1 , a vehicle sunroof frame of the present invention comprises a front rail 1, a pair of curved rails 2 and a pair of straight rails 3 vertically connected to both ends of the front rail 1 through the curved rail 2, wherein the front rail 1 1. A U-shaped structure in which a pair of bent rails 2 and a pair of straight rails 3 are integrally formed.

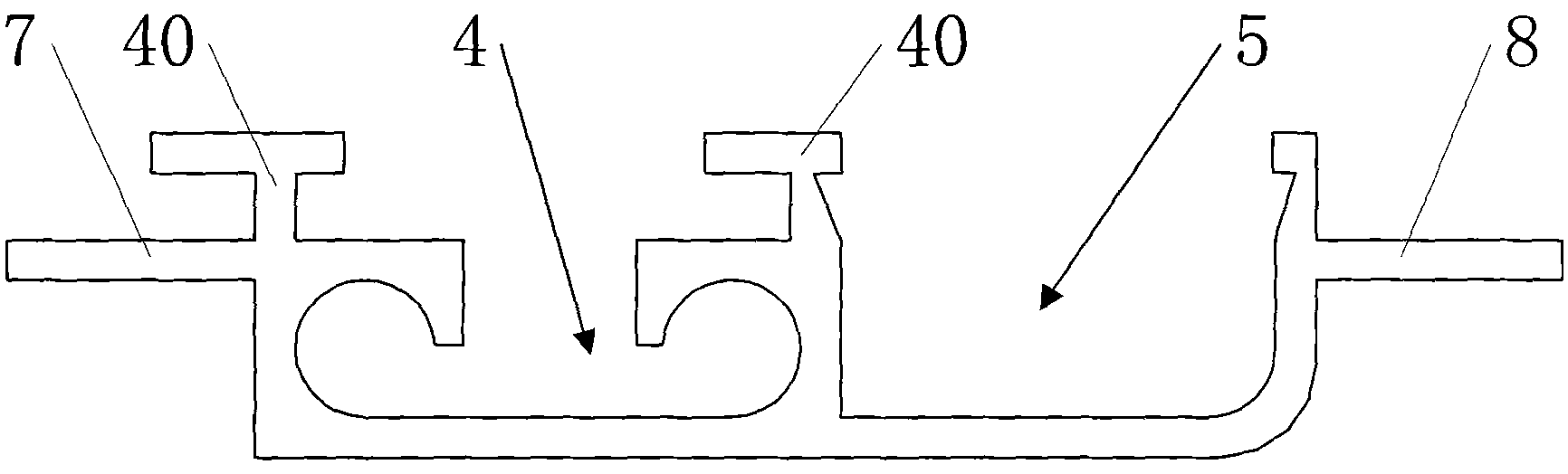

[0032] In the above-mentioned sunroof frame for vehicles, the front crosspiece 1 , the curved section 2 and the straight section 3 are formed by a slide rail groove 4 .

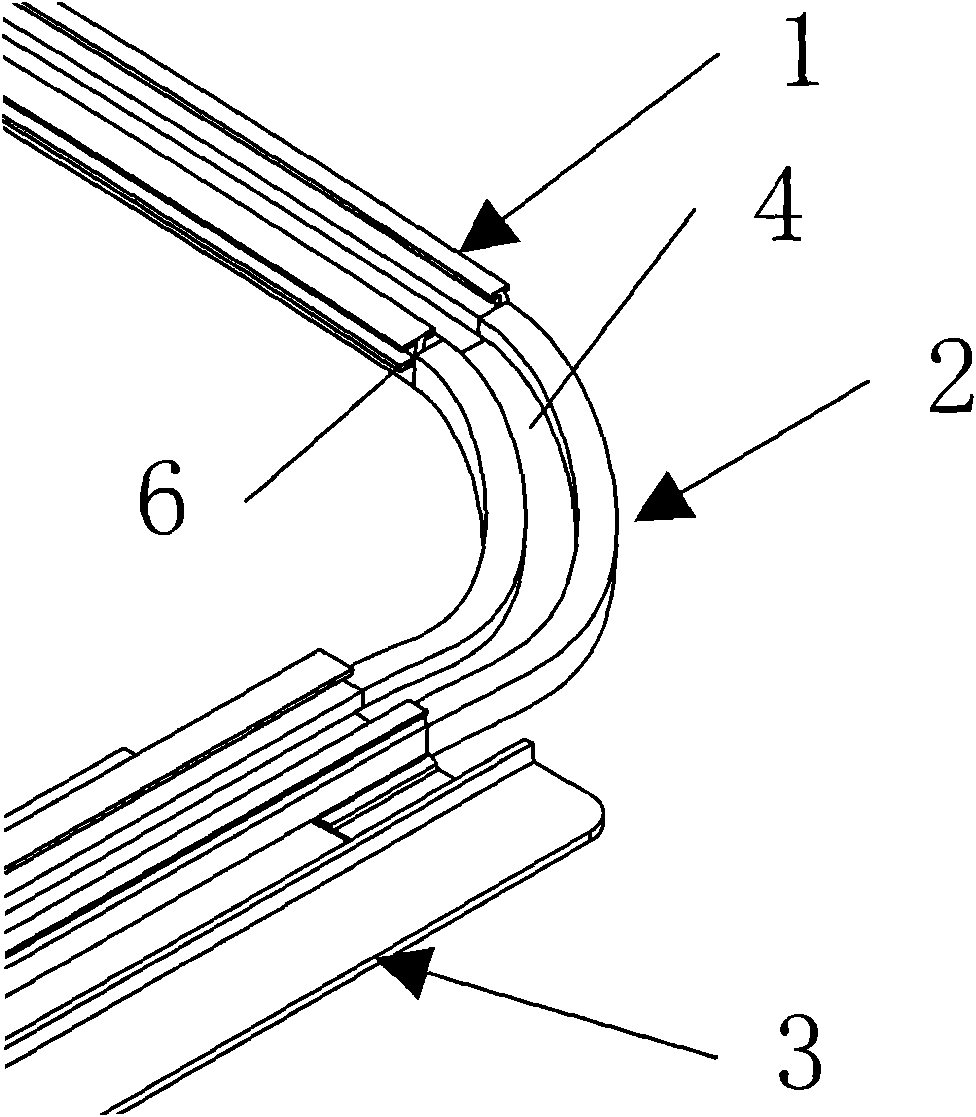

[0033] see figure 2 , the top edge of the outer surface of the outer surface of the groove wall on the inside of the slide rail groove 4 on the front crosspiece 1 extends horizontally and outwardly with a flat plate-shaped lateral wing 6 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com