Shop-assembled solar receiver heat exchanger

A solar energy absorption and heat exchanger technology, applied in solar thermal energy, solar collectors for specific environments, solar thermal power generation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

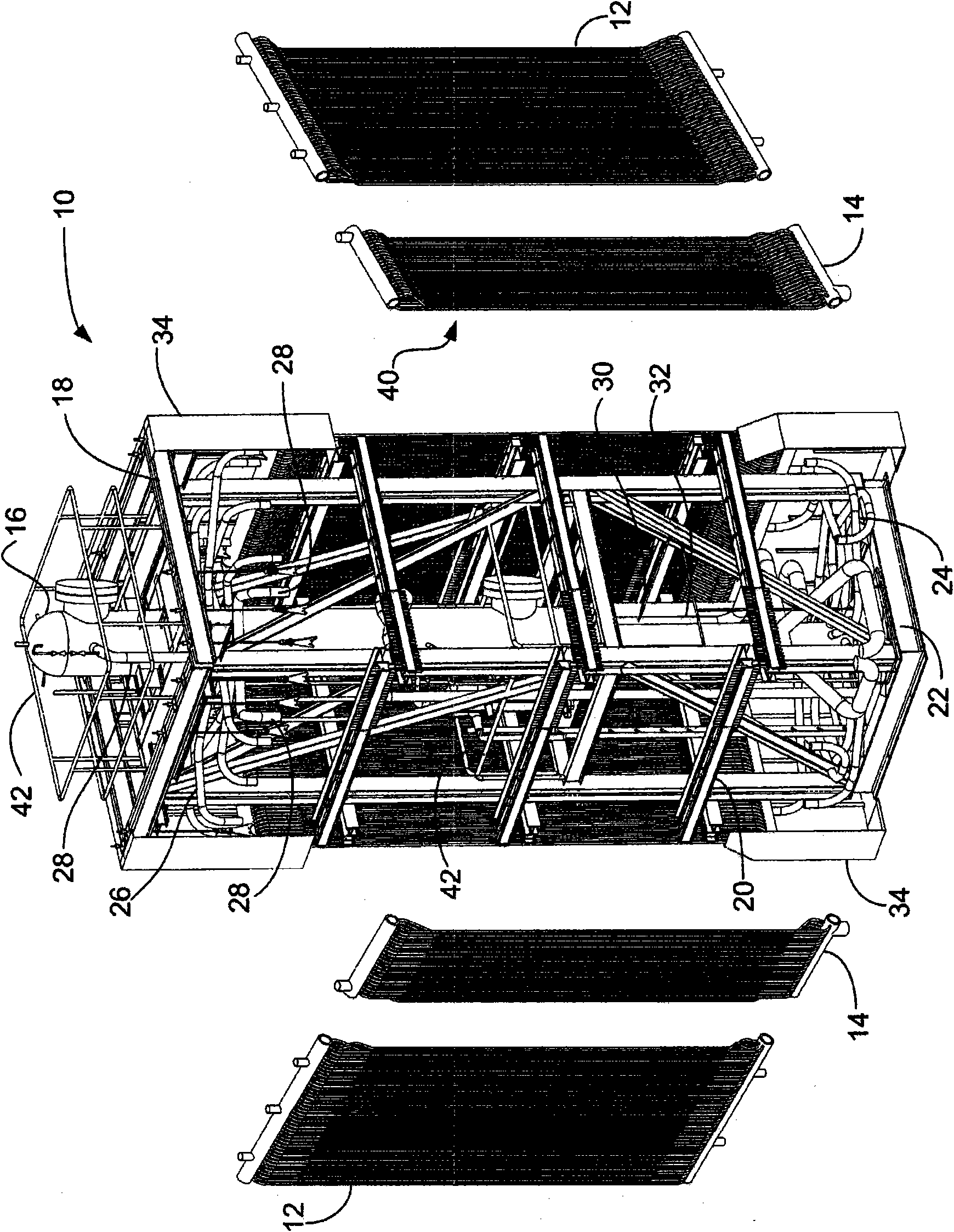

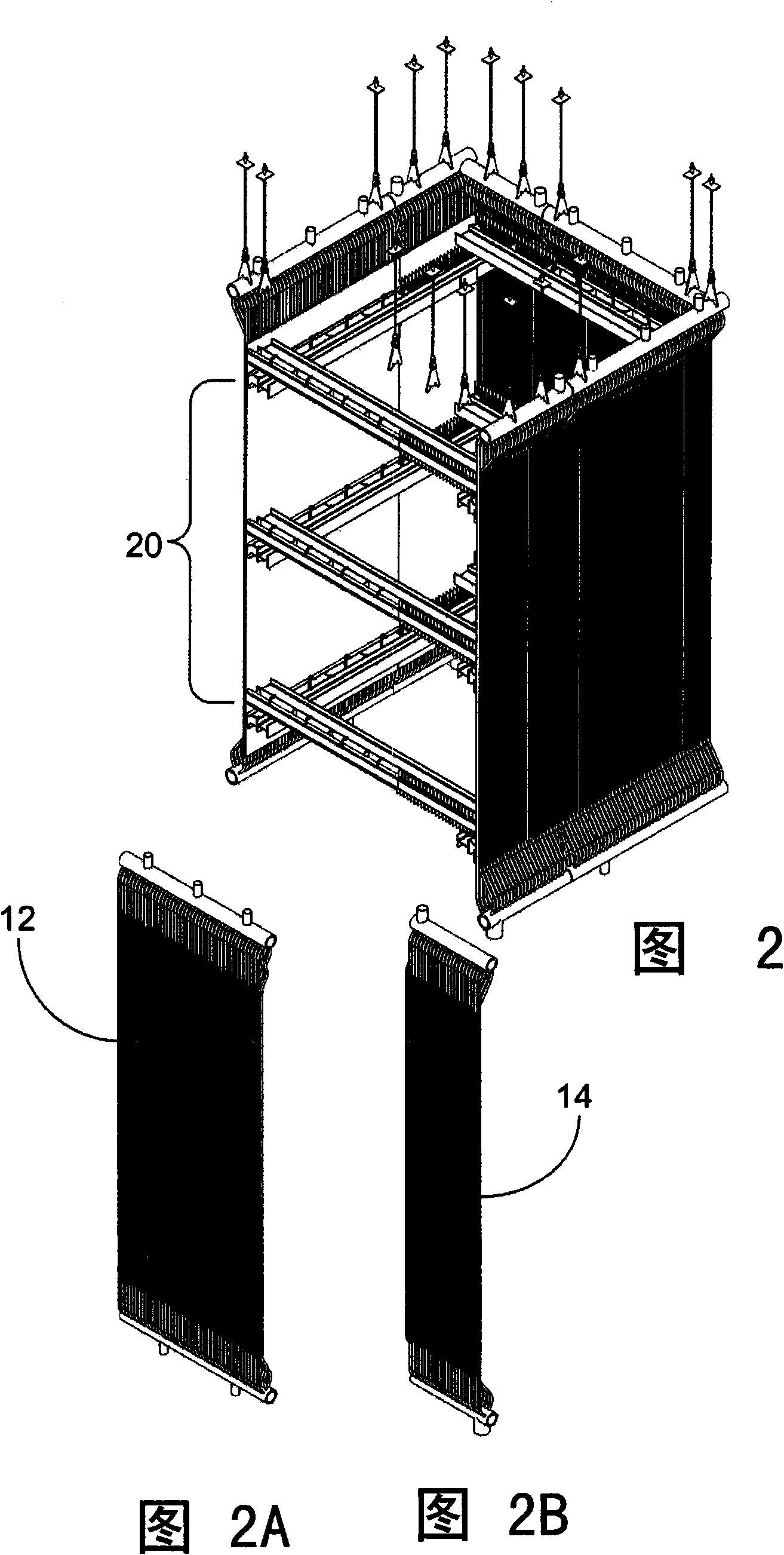

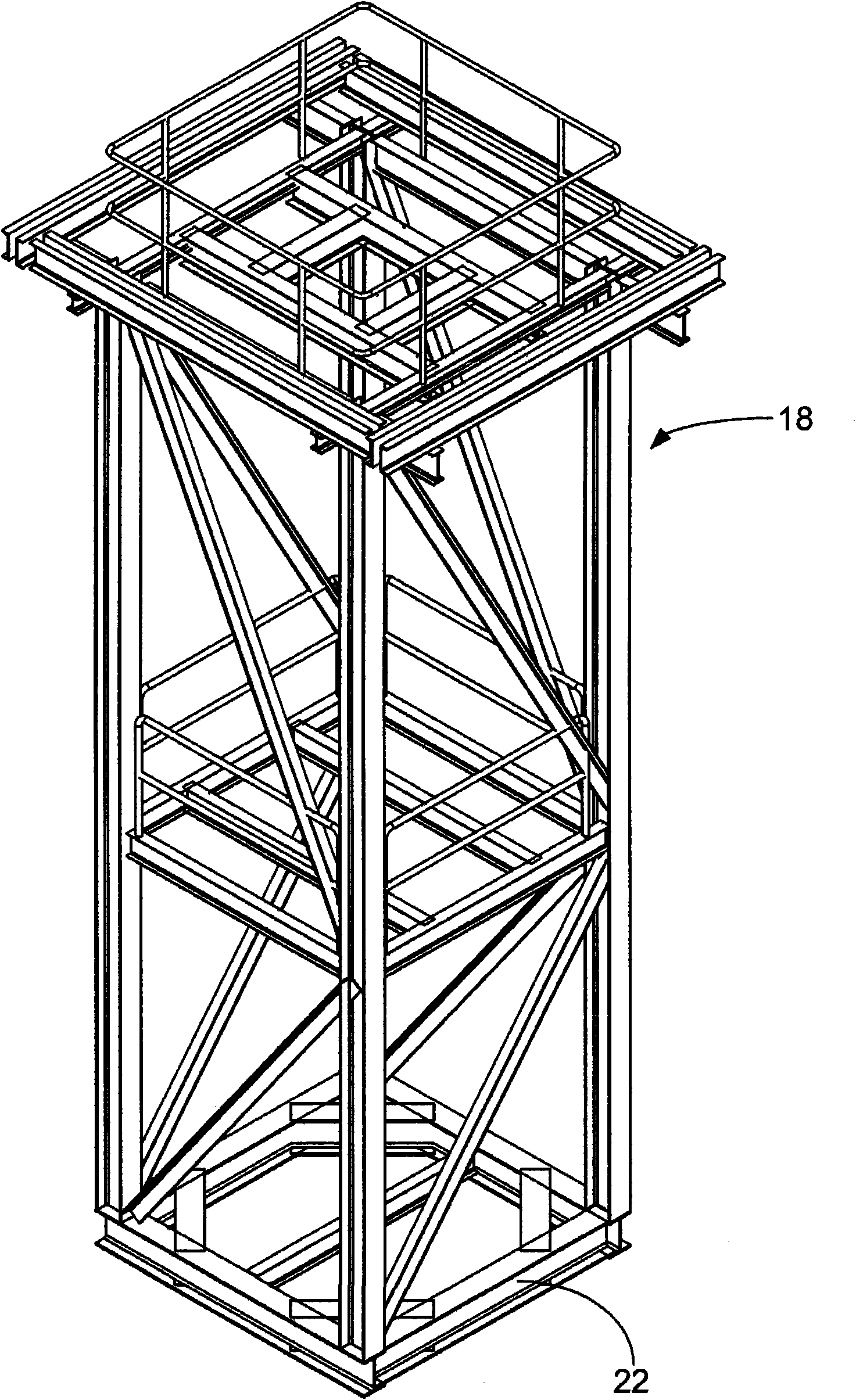

[0034] Reference is now made to the drawings, in which like reference numerals designate identical or functionally similar parts.

[0035] The present invention employs the vertical steam / water separation apparatus described in US Patent No. 6,336,429 to Wiener et al. to separate steam from the steam-water mixture produced by the shop-assembled solar absorber heat exchanger of the present invention. The text of the above-mentioned US Patent No. 6,336,429 to Wiener et al. is incorporated herein as if fully set forth herein. That vertical steam / water separator is structurally and fluidly connected to the heating surface of this shop-assembled solar absorber heat exchanger as part of the shop-assembled design described herein.

[0036] In order to understand the present invention some familiarity with certain terms and principles of heat exchanger, boiler and / or steam generator technology may be required, for which the reader is referred to Steam / its generation and use, Part 40, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com