Speed-adjusting-type permanent-magnet drive system

A permanent magnet drive and speed regulation technology, applied in electric components, electromechanical transmission devices, electrical components, etc., can solve the problems of shortening equipment life, vibration, wear, etc., to avoid harmonics, eliminate vibration, and stabilize speed regulation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

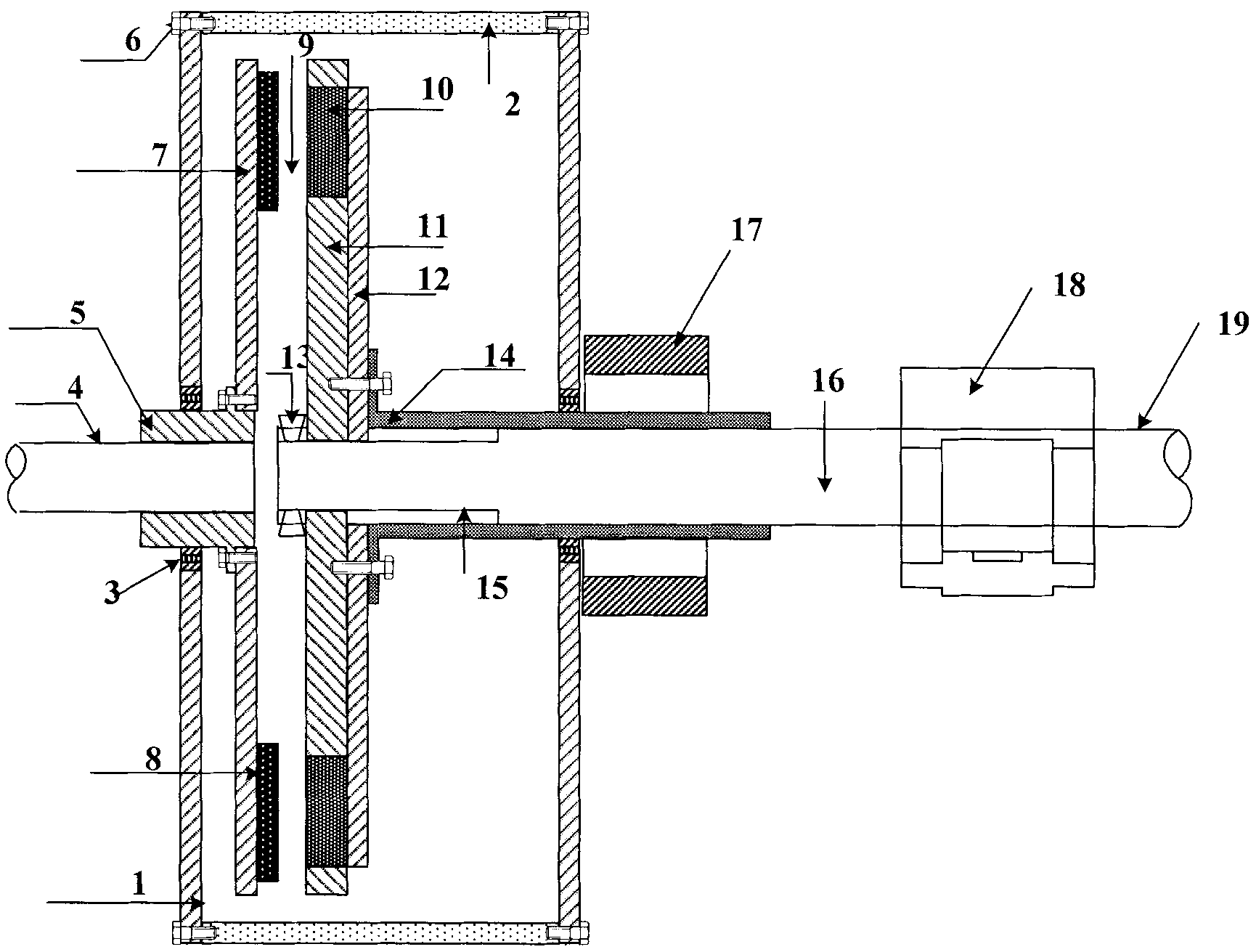

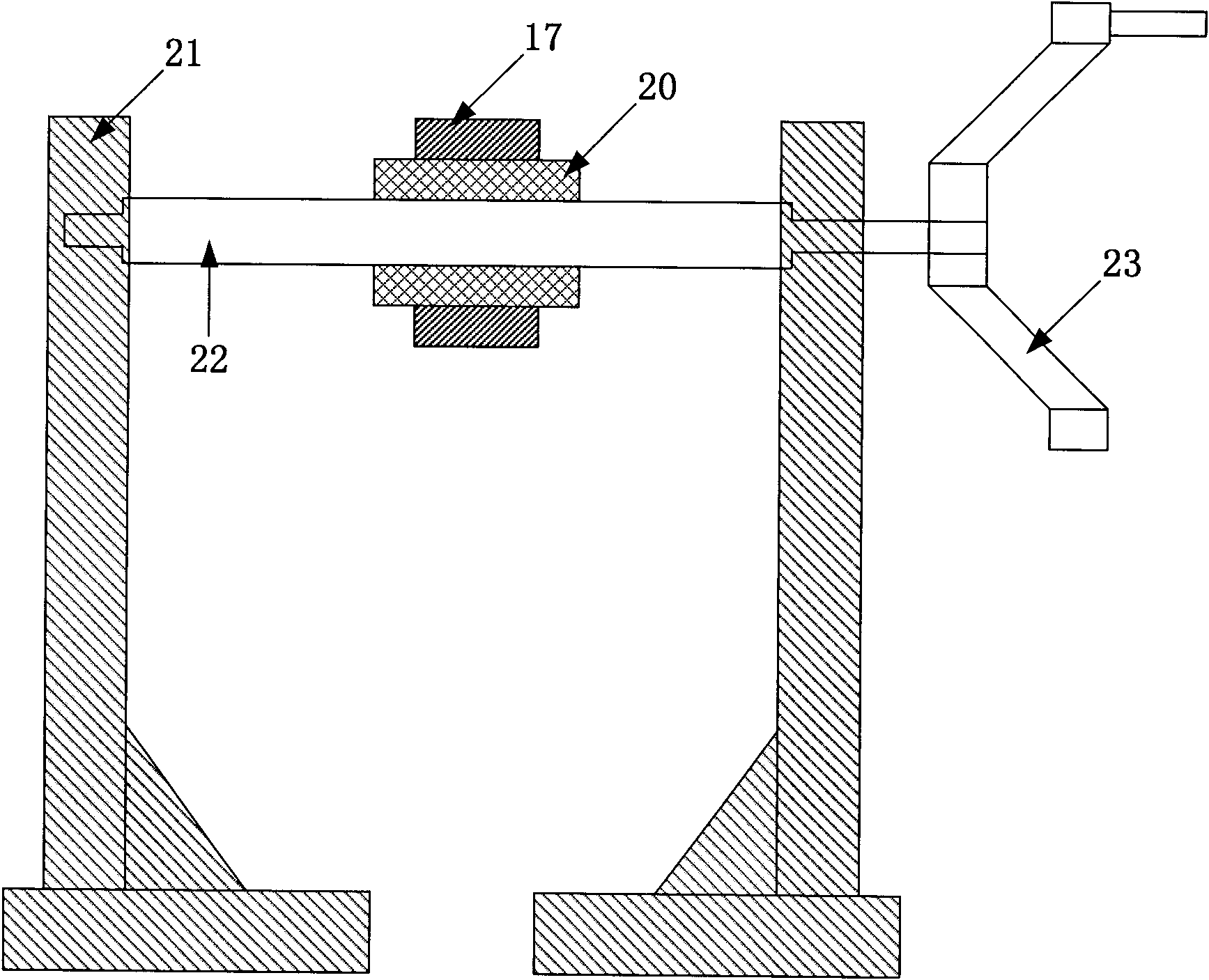

[0016] See figure 1 , a speed-regulating permanent magnet drive system, including a conductor rotor (first rotor), a permanent magnet rotor (second rotor), a lead screw adjuster, a conductor rotor fixedly connected to an input shaft and rotating in unison with the input shaft, and a permanent magnet The rotor is floatingly installed on the additional shaft section of the output shaft, which drives the shaft section to rotate and transmits the torque to the output shaft; there is a gas gap between the conductor rotor and the permanent magnet rotor.

[0017] The first rotor consists of a disc-shaped steel frame 7 and a copper conductive ring 8 fixed on the disc-shaped steel frame 7 , the disc-shaped steel frame 7 is connected with the shaft sleeve 5 and fixed on the input shaft 4 .

[0018] The second rotor consists of an aluminum mounting plate 11 , a steel support plate 12 and a permanent magnet 10 . See image 3 , The permanent magnet 10 is embedded in the mounting plate 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com