Integral cooling device for high-power optical fiber laser or amplifier

A technology for fiber lasers and fiber amplifiers, used in lasers, laser parts, phonon exciters, etc., can solve the inconvenience of high-power fiber lasers or amplifier modularization, cannot provide pump coupler cooling at the same time, and fiber length is limited. and other problems to achieve the effect of increasing the scope of application, preventing fusing or aging, and running for a long time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention should not be limited thereby.

[0016] Figure 1 to Figure 6 A specific example of the invention is given.

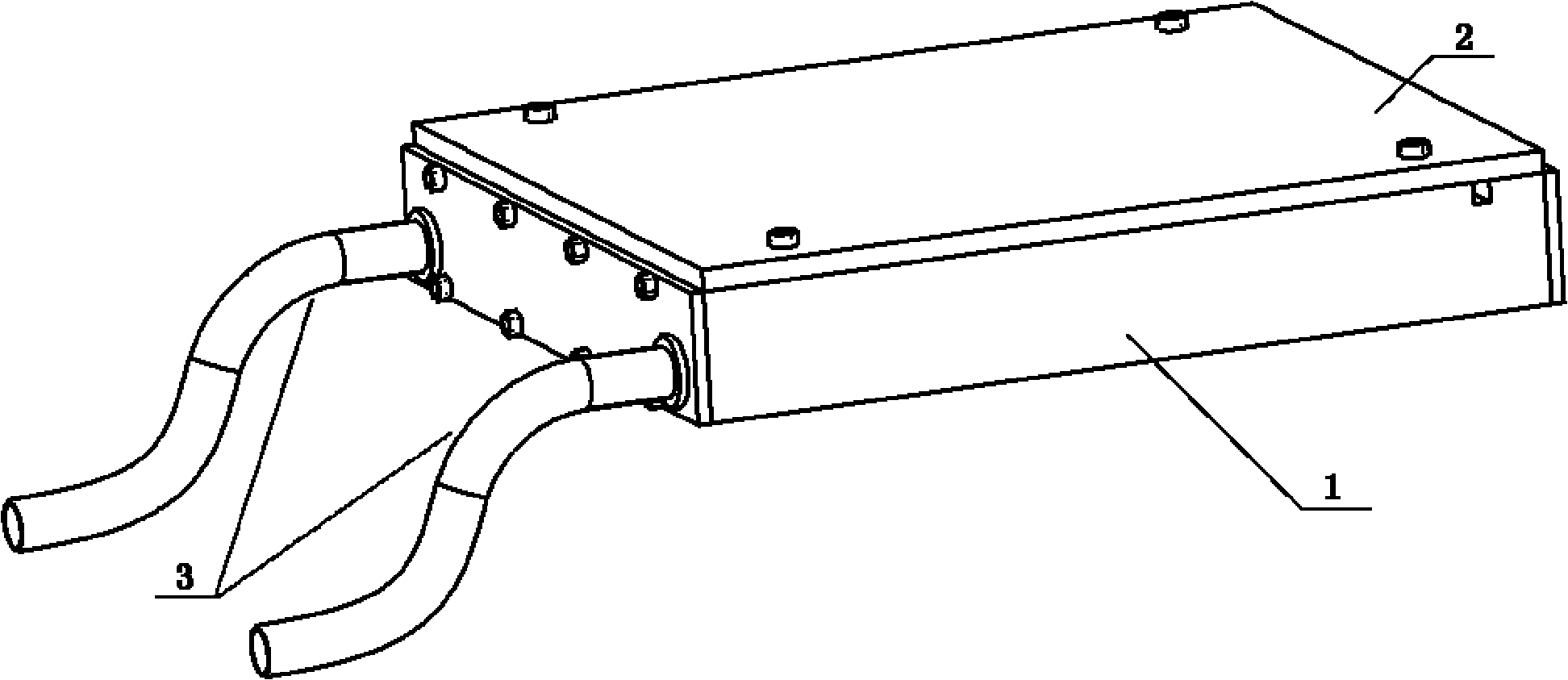

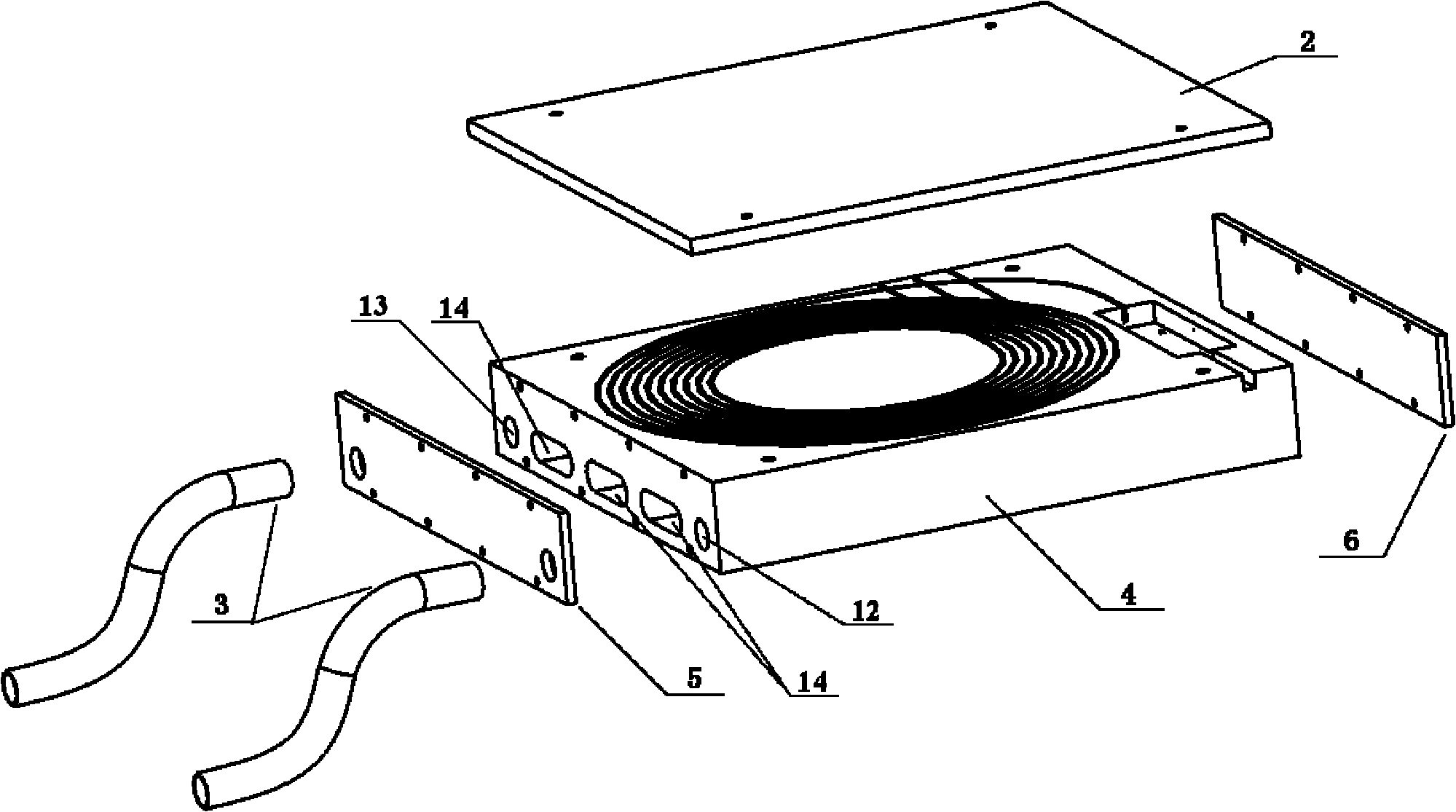

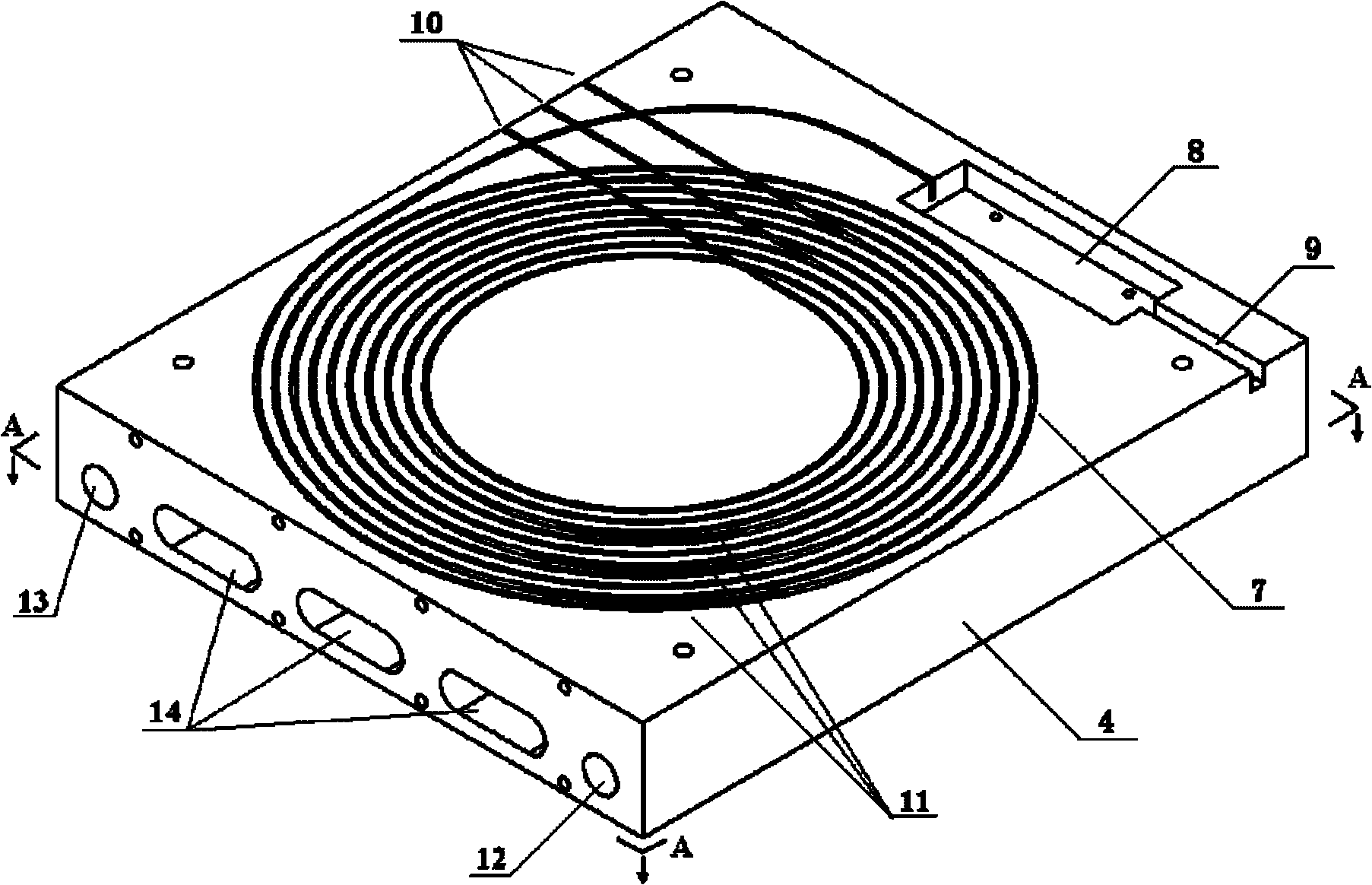

[0017] figure 1 It is a schematic diagram of the external structure of a specific embodiment of the cooling device provided by the present invention. As shown in the figure, the cooling device includes a cooling plate 1 and a heat conduction cover plate 2 , and is connected to a water cooler through a conduit 3 . figure 2 for figure 1 The internal structure schematic diagram of the illustrated embodiment, as shown in the figure, the cooling plate 1 is composed of a cooling plate main body 4 , a front sealing cover 5 and a rear sealing cover 6 . The main body of the cooling plate 4 is a flat metal plate, and the channel 14 runs through the inside so that the cooling liquid can flow ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com