Papermaking sterilization preservative

A technology of bactericidal preservatives and emulsifiers, applied in paper and other fields, can solve problems such as difficult microbial control, achieve the effects of inhibiting micro-growth and reproduction, eliminating interfering substances, and broadening the spectrum of bacteria

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the papermaking antiseptic and antiseptic agent of the present invention is as follows: mix and dissolve thiocyanate, dithiocyanomethane and a certain amount of solvent, add the emulsifier and stir evenly, slowly add the polyguanidine aqueous agent, stir evenly, and discharge the material Barreled. Or mix and dissolve the benzene thiamine, methane dithiocyanate and a quantitative solvent, add the emulsifier and stir evenly, slowly add it to the polyguanidine aqueous agent, stir evenly, and then discharge the material into a bucket.

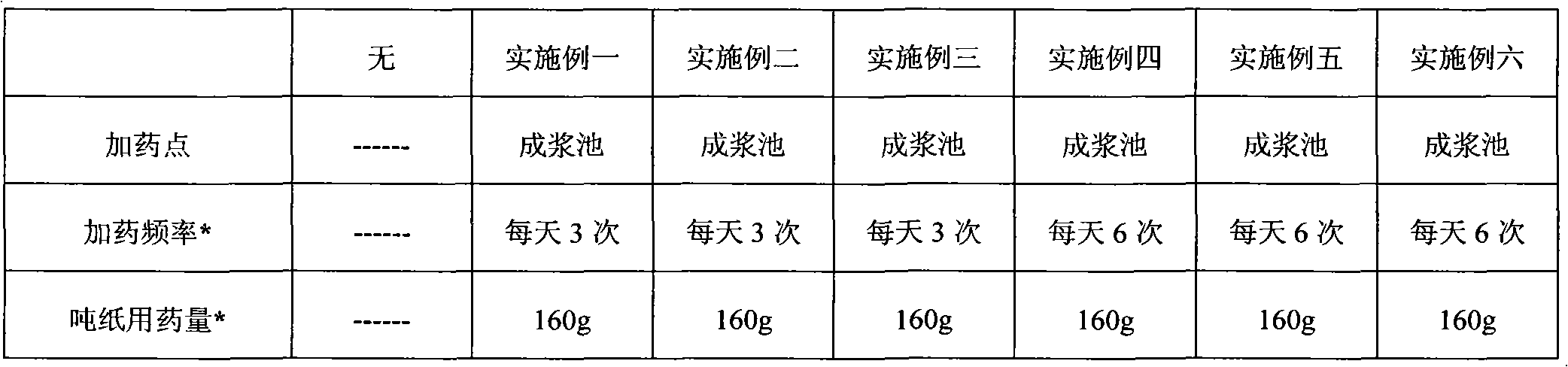

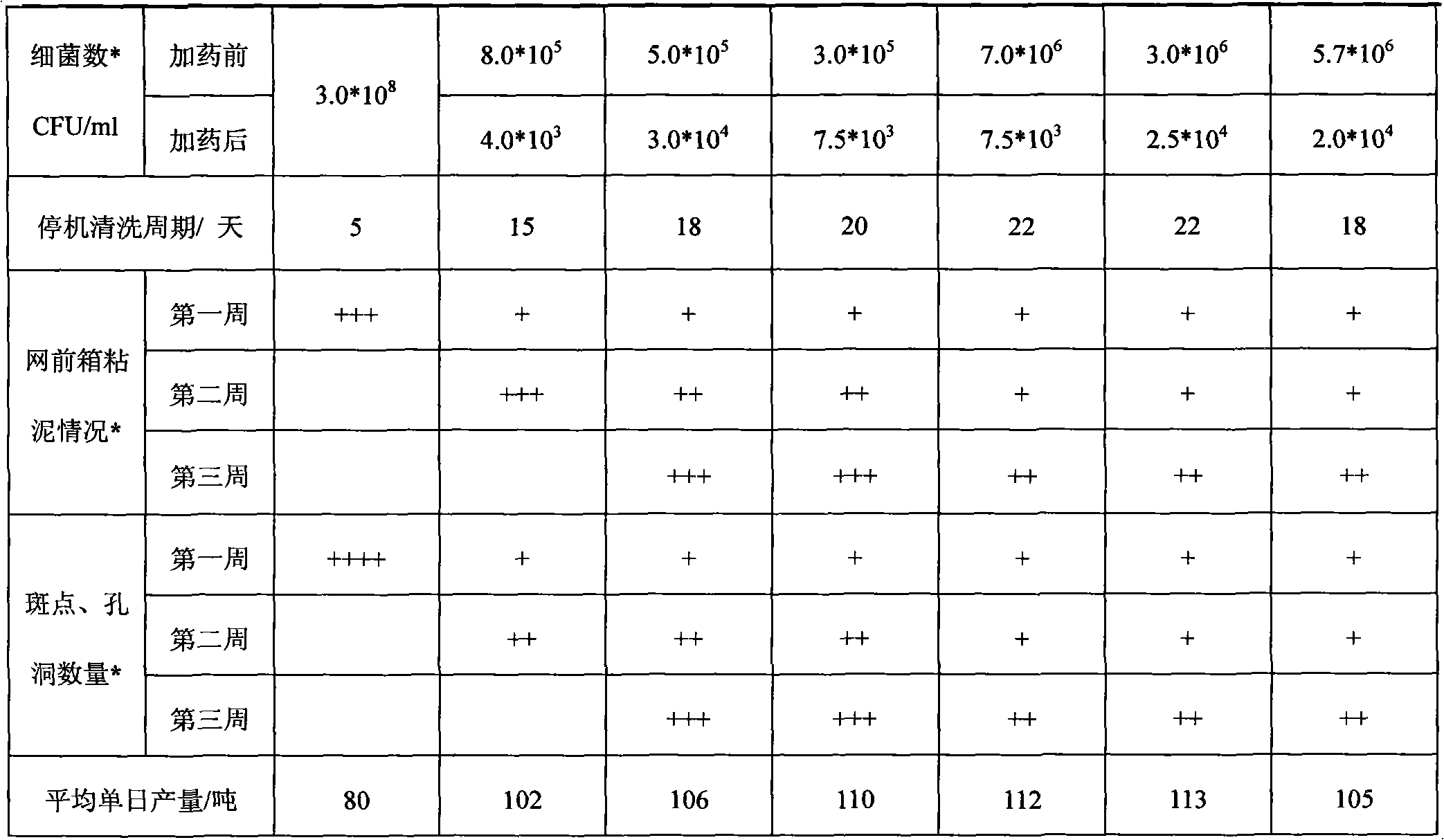

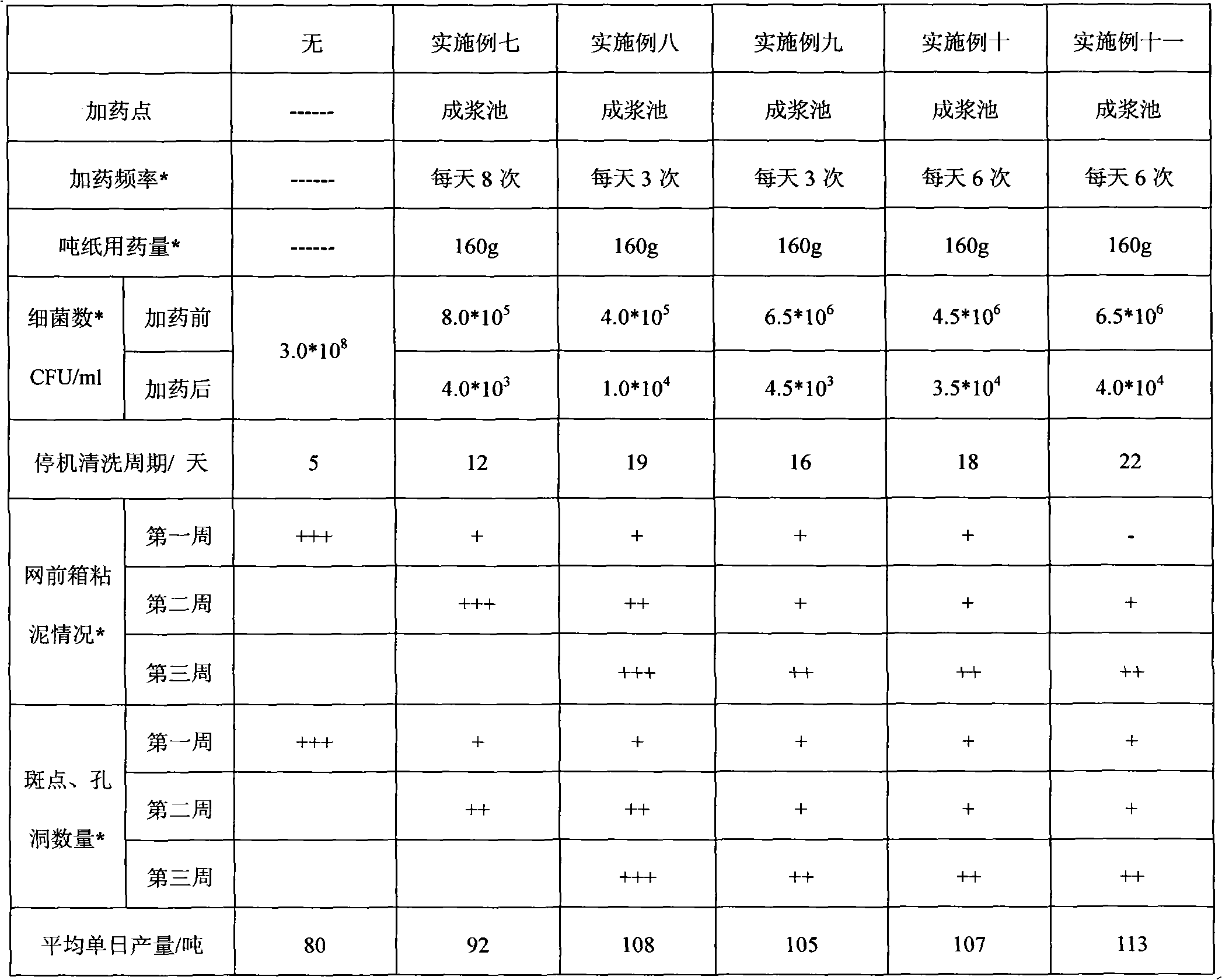

[0022] When the papermaking antiseptic preservative provided by the present invention is used, different dosing points, dosing amounts and dosing methods can be selected according to specific production conditions. It is generally recommended to add it in the pulping tank, the broken paper tank, the high-position tank, the white tank under the net, etc.; generally, the intermittent dosing method is used, and the medic...

Embodiment 1

[0025] The specific composition of the papermaking antiseptic preservative in this embodiment is as follows:

[0026] Take 83.33 parts by weight of benzothiazide (30wt% TCMTB, that is, the content of thiocyanomethylthiobenzothiazole in the papermaking sterilization preservative is 25%), 4 parts by weight of solvent, and 6 parts by weight of emulsifier After stirring uniformly, slowly add 6.67 parts by weight of polyguanidine aqueous solution (75% polyhexamethylene guanidine hydrochloride, that is, the content of polyhexamethylene guanidine hydrochloride in the papermaking sterilization preservative is 5%), and stir evenly Discharge into barrels.

[0027] Wherein: the solvent is a mixed solvent of isopropanol and 3-methyl-1-butanol with a weight ratio of 5:2. The emulsifier is polyethylene glycol 200 and Span 40 in a weight ratio of 2:1.

Embodiment 2

[0029] The specific composition of the papermaking antiseptic preservative in this embodiment is as follows:

[0030] Take 66.67 parts by weight of benzothiazide (30% TCMTB), 5 parts by weight of dithiocyanomethane (MBT), 15.66 parts by weight of solvent, stir to dissolve, add 6 parts by weight of emulsifier and stir evenly, then slowly add 6.67 parts by weight of polyguanidine aqueous agent (75% polyhexamethylene guanidine hydrochloride), stirred uniformly, and discharged into buckets. Wherein: the solvent is a mixed solvent of 3-methyl-1-butanol, xylene and tetrahydrofuran in a weight ratio of 2:5:10. The emulsifier is polyethylene glycol 200, polyethylene glycol 600 and Span 40 in a weight ratio of 2:1:2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com