Device for physically treating industrial circulating water

A technology for industrial circulating water and treatment devices, which is applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc. It can solve problems such as high cost, troublesome operation, and increased suspended solid impurities. Achieve the effect of low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

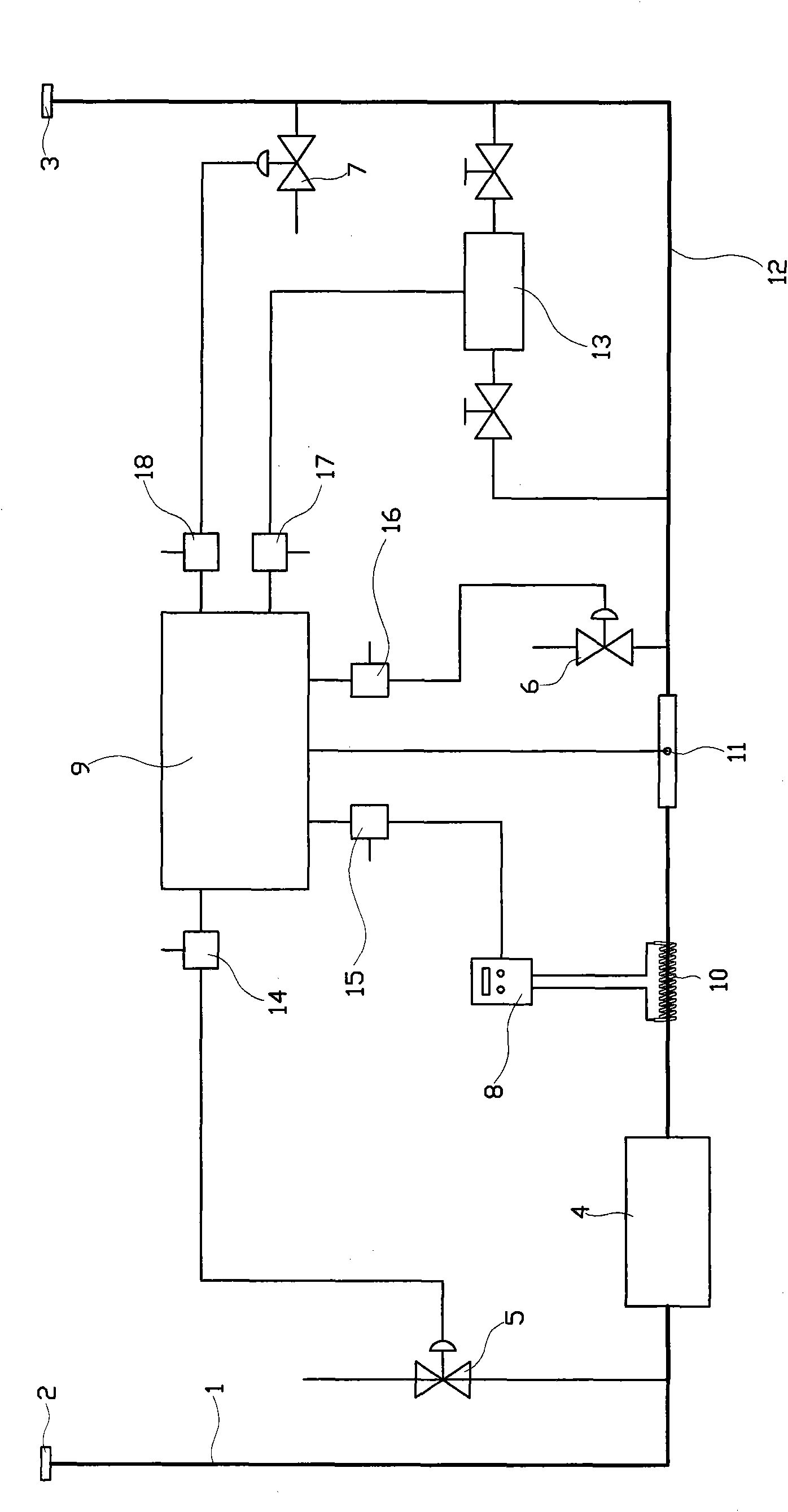

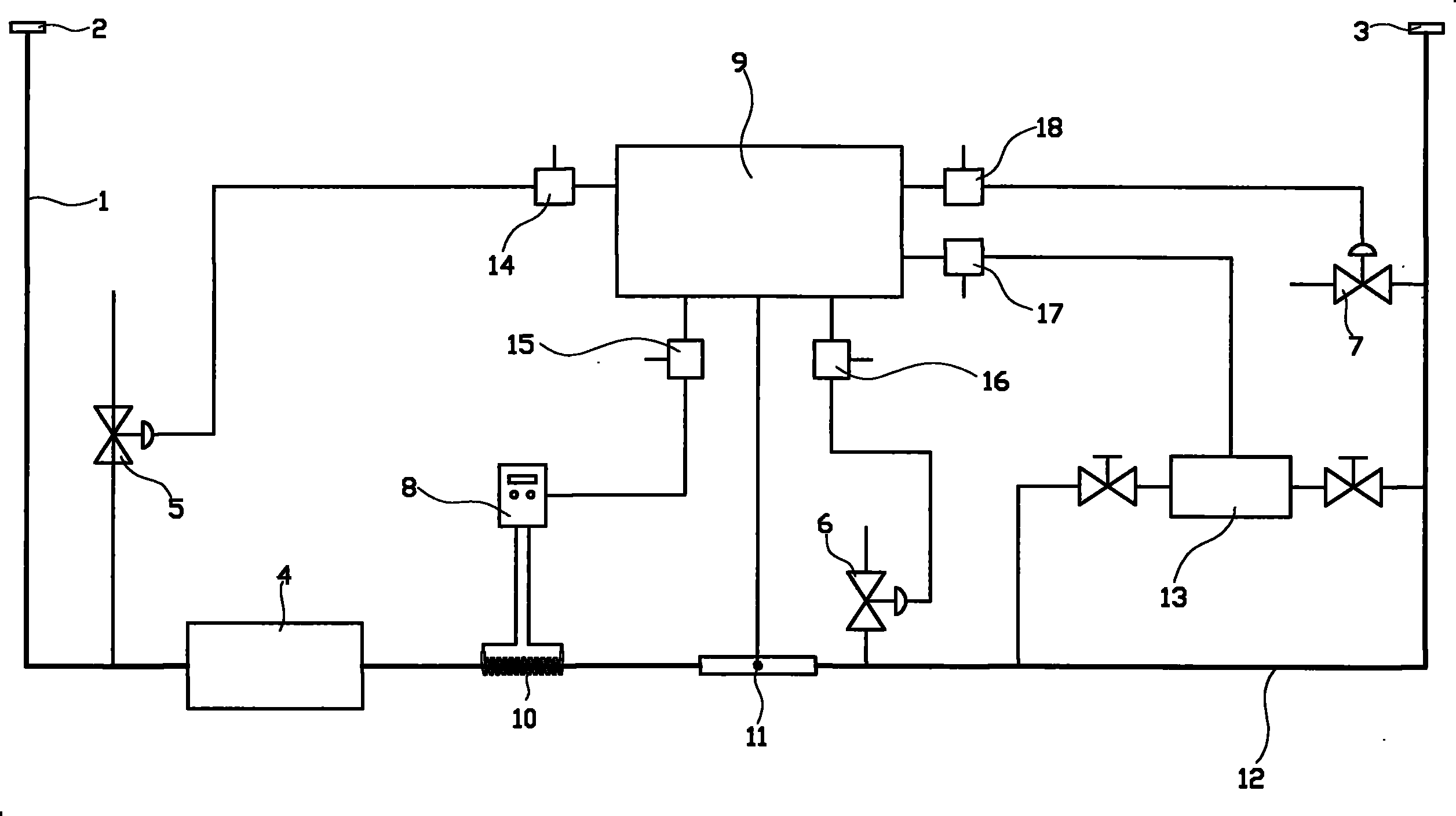

[0017] figure 1 Among them, the industrial circulating water physical method treatment device has a water pipe 1, the water pipe has inlet and outlet ports 2, 3, a media filter 4 is connected in series in the water pipe, and there is a lateral replenishment between the media filter and the water inlet Valve 5, there is a side blowdown valve between the medium filter and the water outlet, and the side blowdown valve has two side blowdown valves 6 and 7, front and rear. The cylindrical solenoid coil 10 of the electronic descaling instrument is wound on the water pipe between the filter and the front sewage solenoid valve, and the solenoid coil is connected with the main engine 8 of the electronic descaling instrument, and the solenoid coil is connected with the front sewage electromagnetic valve. Conductivity sensor 11 is arranged in the water pipe between the valves, and conductivity sensor is connected with conductivity real-time analyzer 9, and conductivity real-time analyzer...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com