Assembly component of automobile clutch cable on front wall board of automobile

A technology for assembling components and front wall panels, used in vehicle components, control devices, transportation and packaging, etc., to solve problems such as gasket damage and impact on sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings.

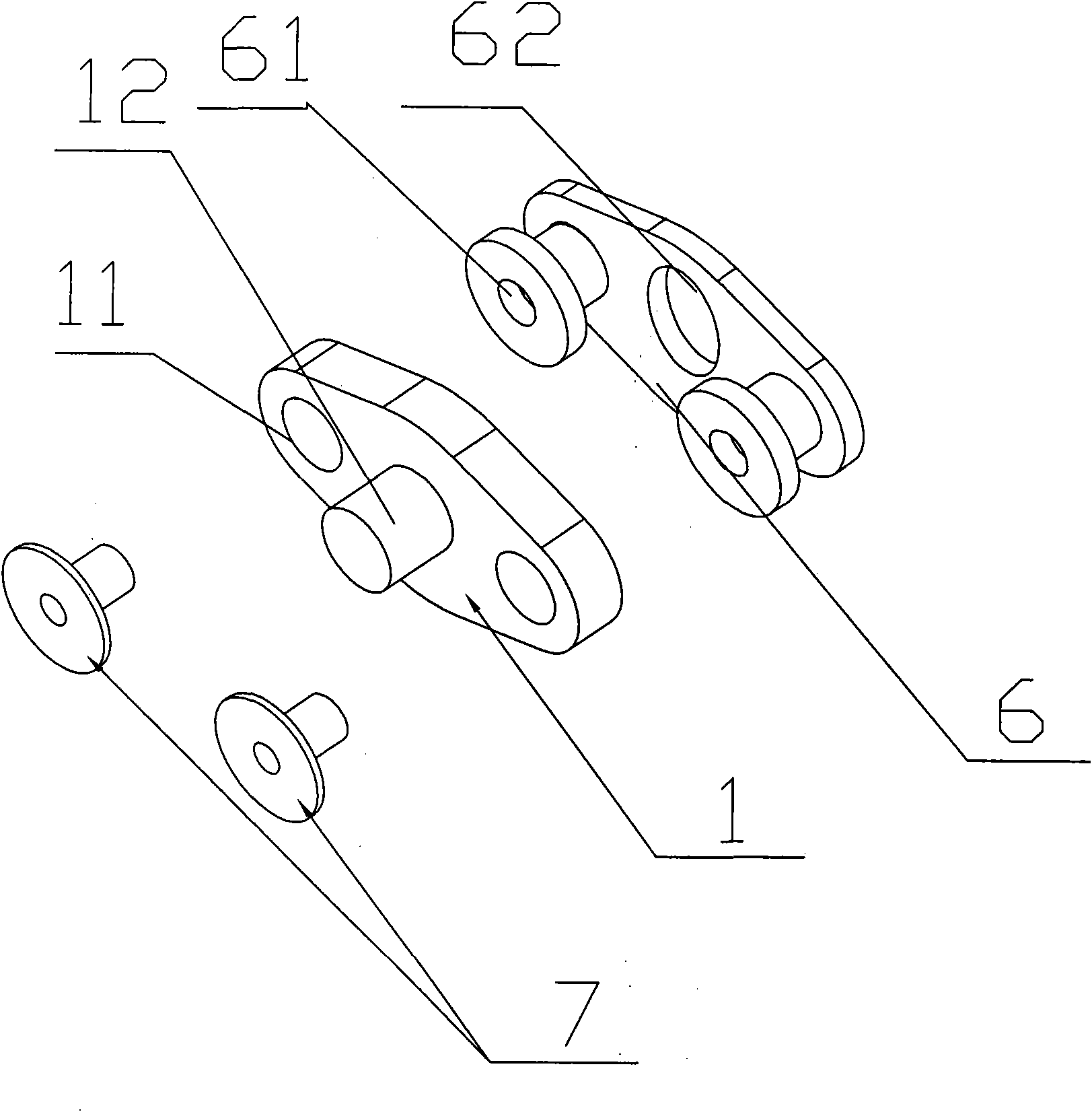

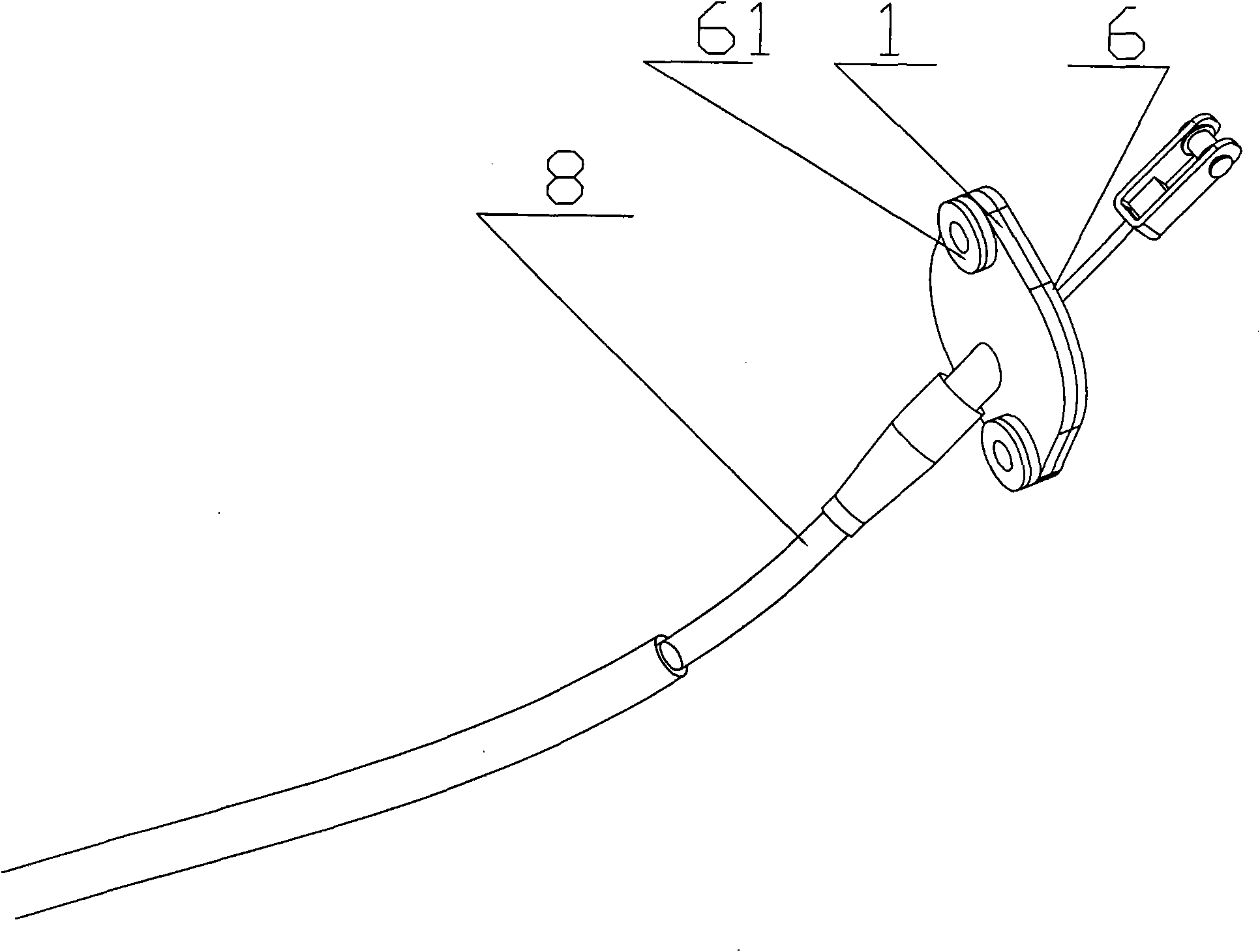

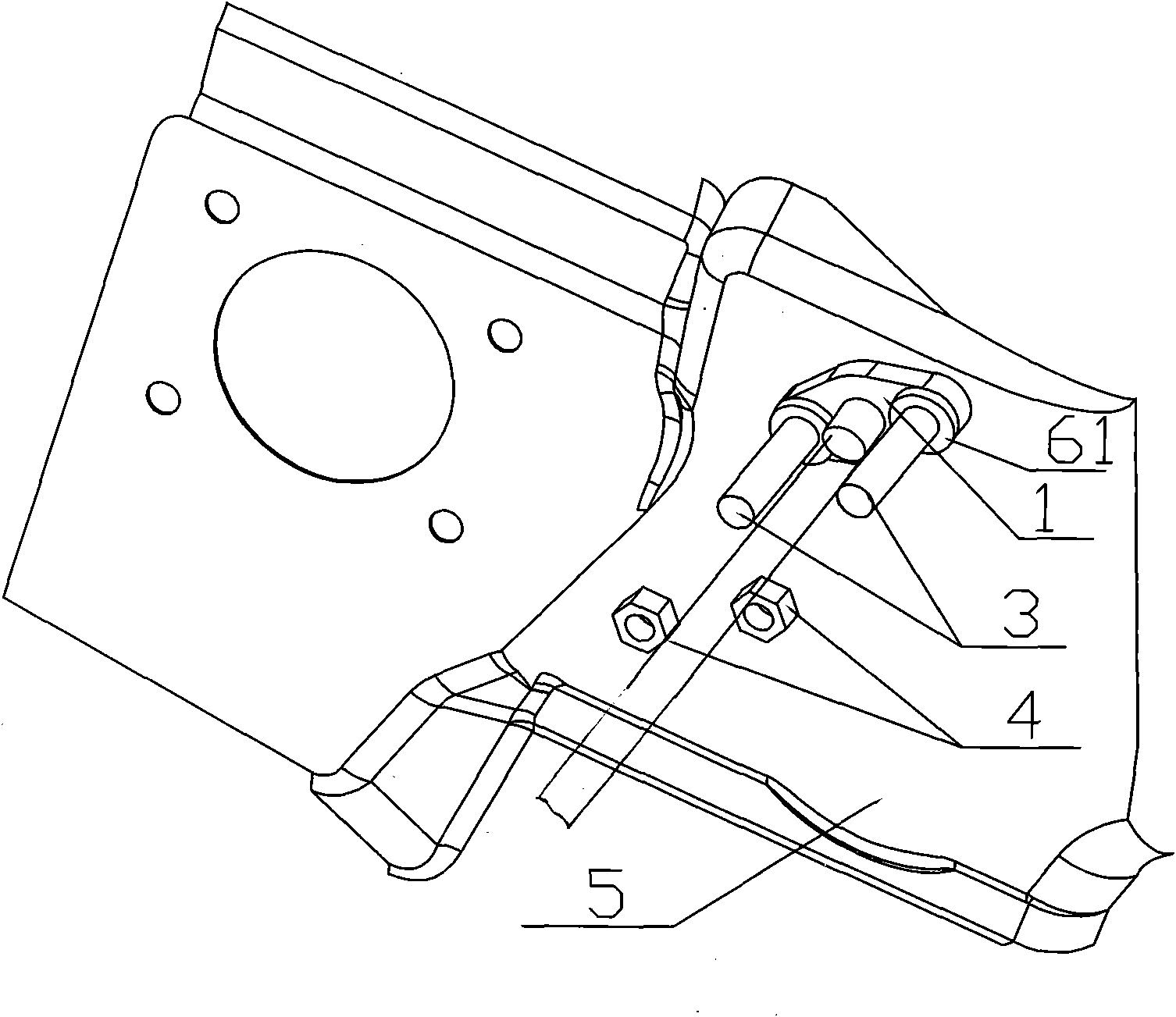

[0013] see figure 1 , the assembly assembly includes a metal cover plate 1, a rubber gasket 6 and two bolt sleeves 7. The metal cover plate 1 cooperates with the front wall plate 5 of the automobile as a metal casting, but due to the poor damping performance and sealing performance between the metal and the metal, a rubber gasket 6 is added. The center of the metal cover plate has the through hole 12 that the clutch cable passes through, and the two ends have the mounting hole 11 that is assembled with the bolt on the front panel of the automobile. The rubber gasket 6 has the same shape as the metal cover plate 1, and is closely attached to the side of the metal cover plate 1 by the front wall of the car to avoid direct contact between the metal cover plate and the front wall plate and to play a sealing role. There is also a via hole 62 for the passage of the clutch ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com