Liquid crystal sealing agent and liquid crystal display cell using the same

A liquid crystal sealant and inorganic filler technology, applied in instruments, optics, other chemical processes, etc., can solve problems such as viscosity changes over time, achieve excellent gap forming ability, long pot life, and improve the effect of yield

Active Publication Date: 2010-10-13

NIPPON KAYAKU CO LTD

View PDF10 Cites 7 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

On the other hand, since the Michael reaction can also proceed at room temperature, the viscosity changes over time.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1、2 and comparative example 1

Embodiment 1 Embodiment 2 comparative example 1

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Joint strength | aaaaa | aaaaa |

Login to View More

Abstract

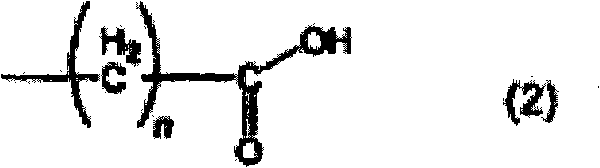

Disclosed is a liquid crystal sealing agent having long working life and excellent coatability to substrates, which is accelerated in the curing reaction of a resin, thereby increasing adhesiveness while suppressing contamination of liquid crystals by the resin. Specifically disclosed is a liquid crystal sealing agent containing (a) a polyvalent carboxylic acid having an isocyanuric ring structure represented by the general formula (1) below, (b) a curable resin composed of an epoxy resin and / or a (meth)acrylated epoxy resin, (c) a thermosetting agent, and (d) an inorganic filler. (In the formula (1), R1-R3 independently represent a hydrogen atom or a group represented by the following formula (2): ((2) wherein n represents an integer of 1-6). In this connection, R1-R3 are not hydrogen atoms at the same time).

Description

technical field This invention relates to a liquid crystal sealing compound and a liquid crystal display cell (cell) using the liquid crystal sealing compound. More specifically, the present invention relates to a liquid crystal sealant suitable for the manufacture of a liquid crystal display cell in which liquid crystal is dropped into The liquid crystal is sealed by bonding the other substrate to the inside of the bank of the photothermal curing combined use type and thermosetting liquid crystal sealing agent formed on one substrate, and curing the liquid crystal sealing agent. Background technique In recent years, along with the increase in size of liquid crystal display cells, a so-called liquid crystal drop processing method with higher mass productivity has been proposed as a method for manufacturing liquid crystal display cells (see Patent Document 1 and Patent Document 2). Specifically, this method is a method of manufacturing a liquid crystal display cell in which ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): G02F1/1339C08F299/02C08G59/42C09K3/10

CPCC08G18/8116C08F299/02G02F2202/025C08F283/06G02F2001/13415C08G18/3215C08G59/4246G02F1/1339C08F299/00C08G59/4238G02F2202/023G02F1/13415C09K3/1006C09K2003/1059

Inventor 桥本昌典落直之太田英之木田昌博西原荣一今泉雅裕荷见直美

Owner NIPPON KAYAKU CO LTD

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com