Mini combustion-type semiconductor thermo-electric generator

A technology of thermoelectric power generation chips and semiconductors, which is applied in the direction of generators/motors, electrical components, etc., can solve the problems of reduced life, low temperature, heat loss, etc., and achieve the effects of uniform temperature field distribution, small volume, safe and stable work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

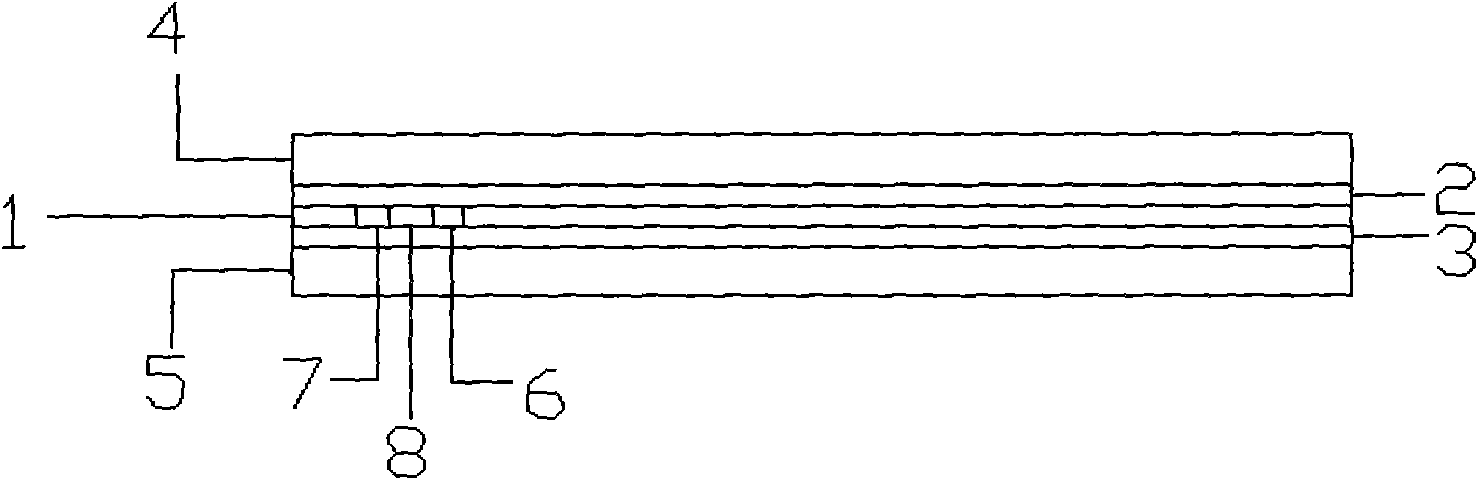

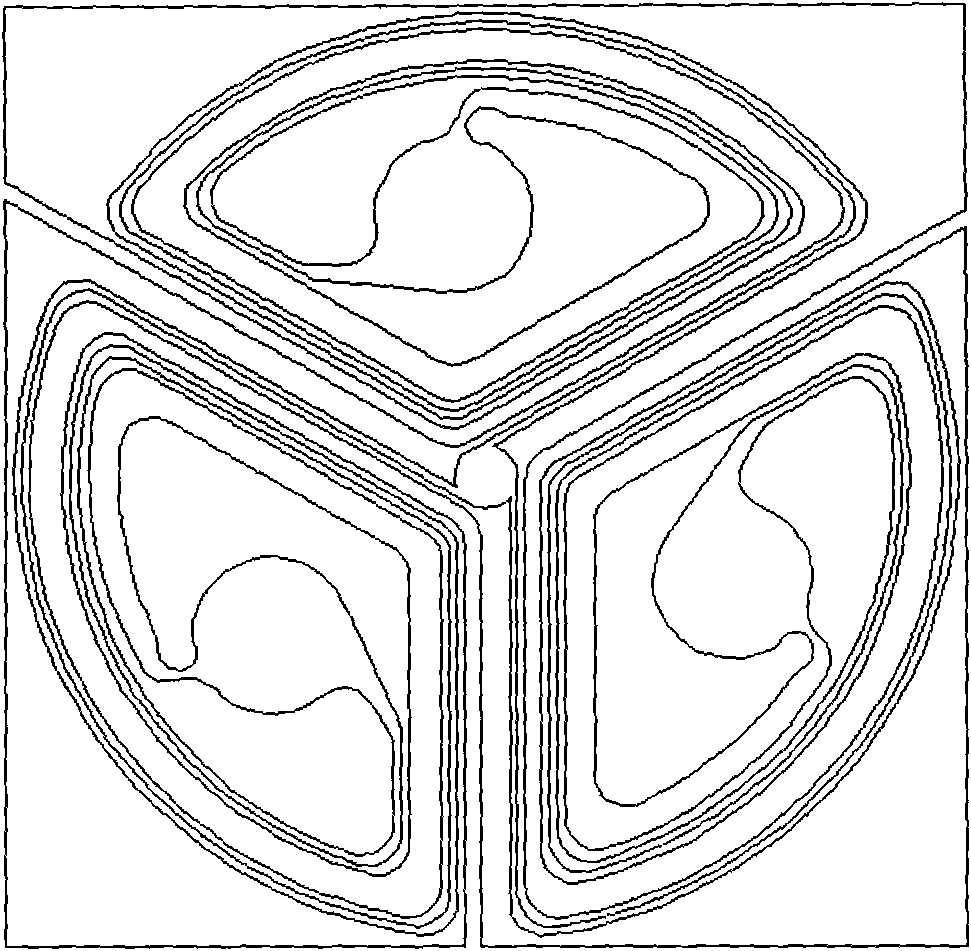

[0027] Referring to the accompanying drawings, the present invention includes an upper thermoelectric generation sheet 4 and a lower thermoelectric generation sheet 5 at the power output end, and a burner 1 with a different pipeline structure, which is usually etched from a high-temperature-resistant and non-conductive silicon wafer or silicon dioxide. Its spiral channel spirals in a circular or square shape or in any suitable shape on the same plane. In the illustrated example, the spiral groove is a square spiral, and its height and width are between 500um and 1mm. For single chamber burners ( figure 2 ), a through hole is provided at the upper thermoelectric generation sheet 4 and the lower thermoelectric generation sheet 5, and at the center position of the upper heat insulation sheet 2 and the lower heat insulation sheet 3, and the electronic ignition device is connected, so that the central through hole of the thermoelectric generation sheet is usually The diameter is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com