Novel air compressor asynchronous motor

A technology for asynchronous motors and air compressors, applied in asynchronous induction motors, electromechanical devices, electrical components, etc., can solve problems such as inaccurate positioning of motor stator cores, poor use of air compressor motors, and unreasonable structural design. Achieve the effect of solving the problem of easy aging, saving maintenance costs, avoiding aging and short turns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

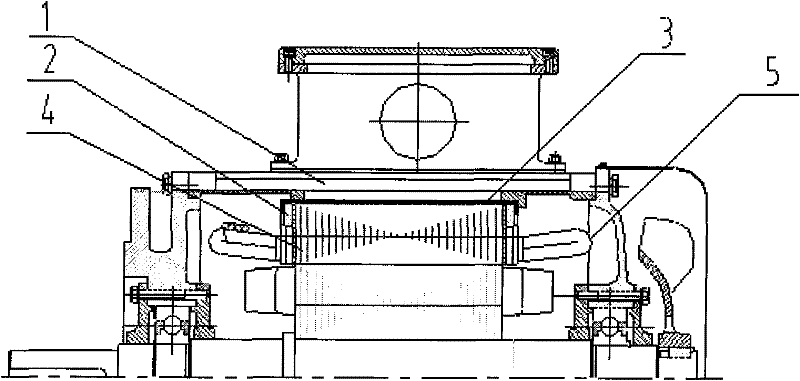

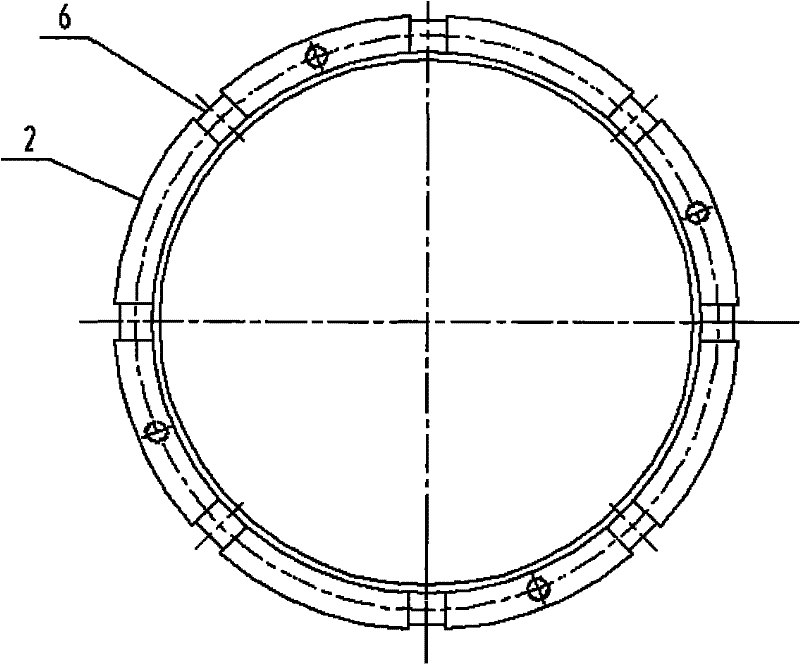

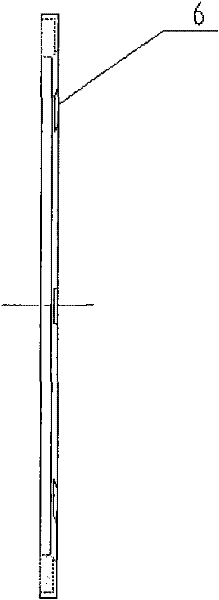

[0023] Air compressor asynchronous motor, including machine base 1, stator core 4 fastened by stator pressure ring 2 and clip 3, stator coil 5 and rotor. One end of the stator core 4 fastened by the stator pressure ring 2 and buckle 3 is positioned on the notch positioning step, and the other end is welded on the machine base 1; The groove 6 where the sheet 3 is fastened, and the buckle 3 is buckled in the groove 6; the first and last three turns of the stator coil 5 are covered with a glass wool sleeve. The motor uses sealed bearings.

[0024] There is a notch positioning step inside the machine base 1 for the axial positioning of the stator core 4 to prevent electromagnetic vibration and electromagnetic noise due to the misalignment between the stator core 4 and the rotor core; the stator pressure for tightening the stator core 4 There is an equally divided groove 6 on the ring 2, which is used to connect with the buckle 3, so that the height of the buckle 3 after the buckl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com