Laboratory icing simulating test method of optical power ground wires (OPGWs)

A laboratory simulation and overhead ground wire technology, which is applied in the field of laboratory simulation ice coating test of special optical fiber cable and optical fiber composite overhead ground wire, can solve the problems of unsatisfactory requirements, undiscovered optical cable technical indicators and requirements, no established test environment and Methods and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

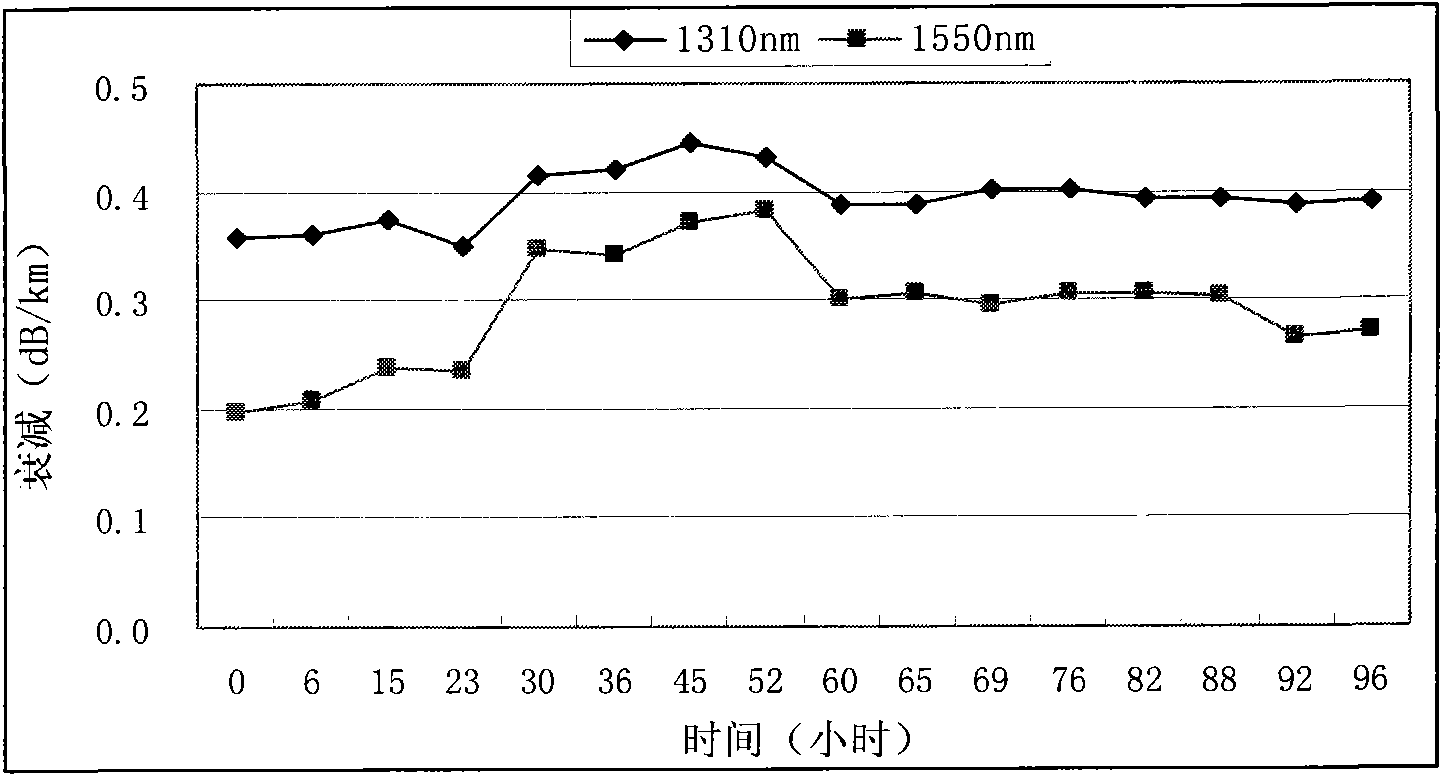

[0041] Firstly, using the spray freezing method in the icing laboratory, the icing test was carried out on the OPGW, and the ice weight data of different thicknesses of ice in nature were simulated and compared, and compared with the theoretical calculation.

[0042] Icing calculated value and actual value verification:

[0043] (1) Weighing the uniced OPGW

[0044] A fiber optic cable sample with a length of 120 cm is weighed, and the weight is 795 g.

[0045] (2) Weighing the ice-coated OPGW

[0046] A fiber optic cable with a length of 120 cm and an ice-covered length of 90 cm is weighed, and the weight is 1580 g.

[0047] (3) Measure the diameter of OPGW and the outer diameter after ice coating

[0048] The diameter of the OPGW measured by a caliper is 15.2mm, and the outer diameter after ice coating is 37mm.

[0049] (4) Ice weight of OPGW icing

[0050] The ice weight of the OPGW covered with ice is equal to the total weight of the optical fiber cable with a length ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com