System and method for dynamically demarcating film thermocouple by adopting laser

A dynamic calibration and laser technology, applied to instruments, scientific instruments, measuring heat, etc., can solve the problem that it is difficult to obtain the pulse width of the laser excitation signal, and achieve the effect of strong practicability, high precision, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

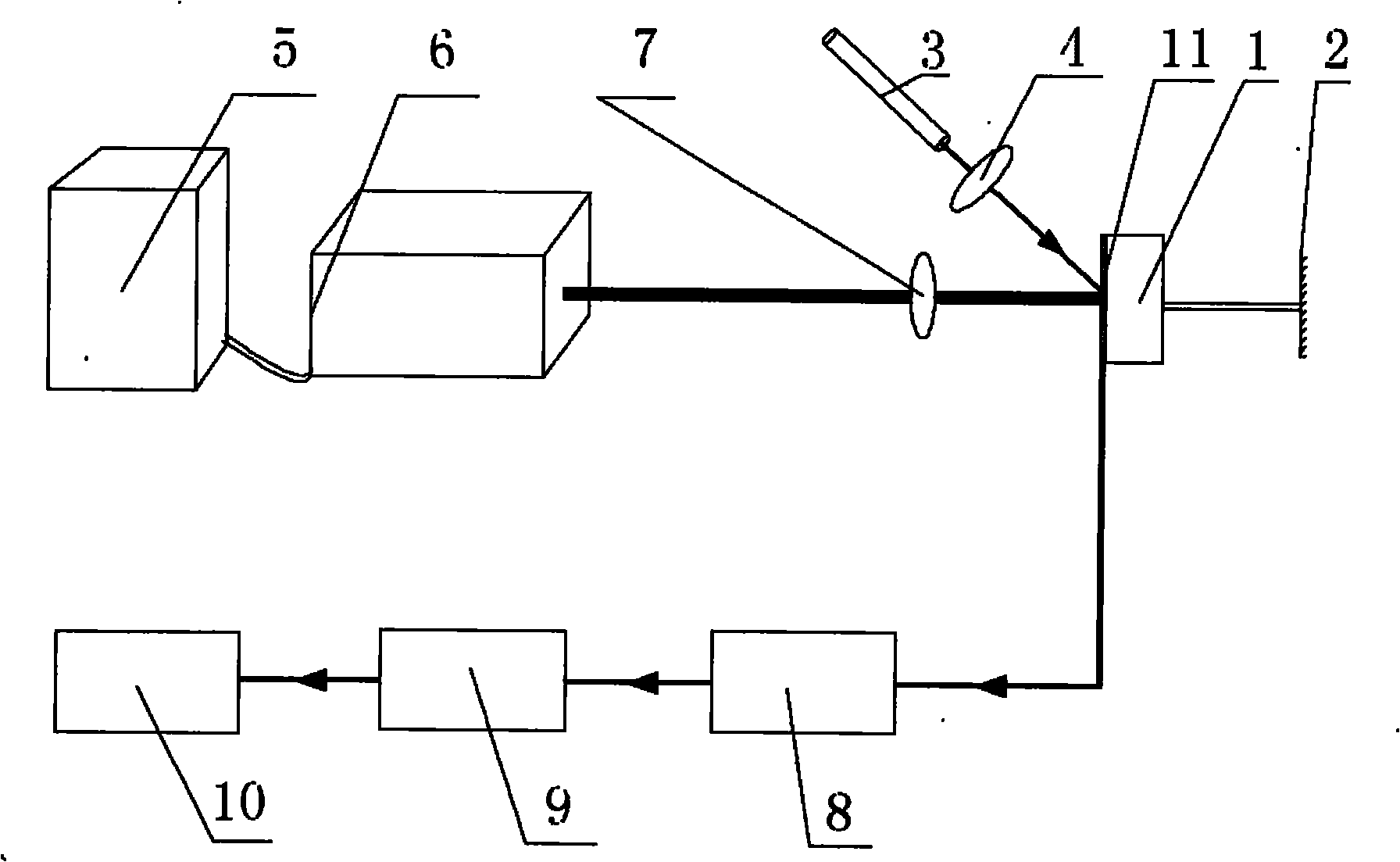

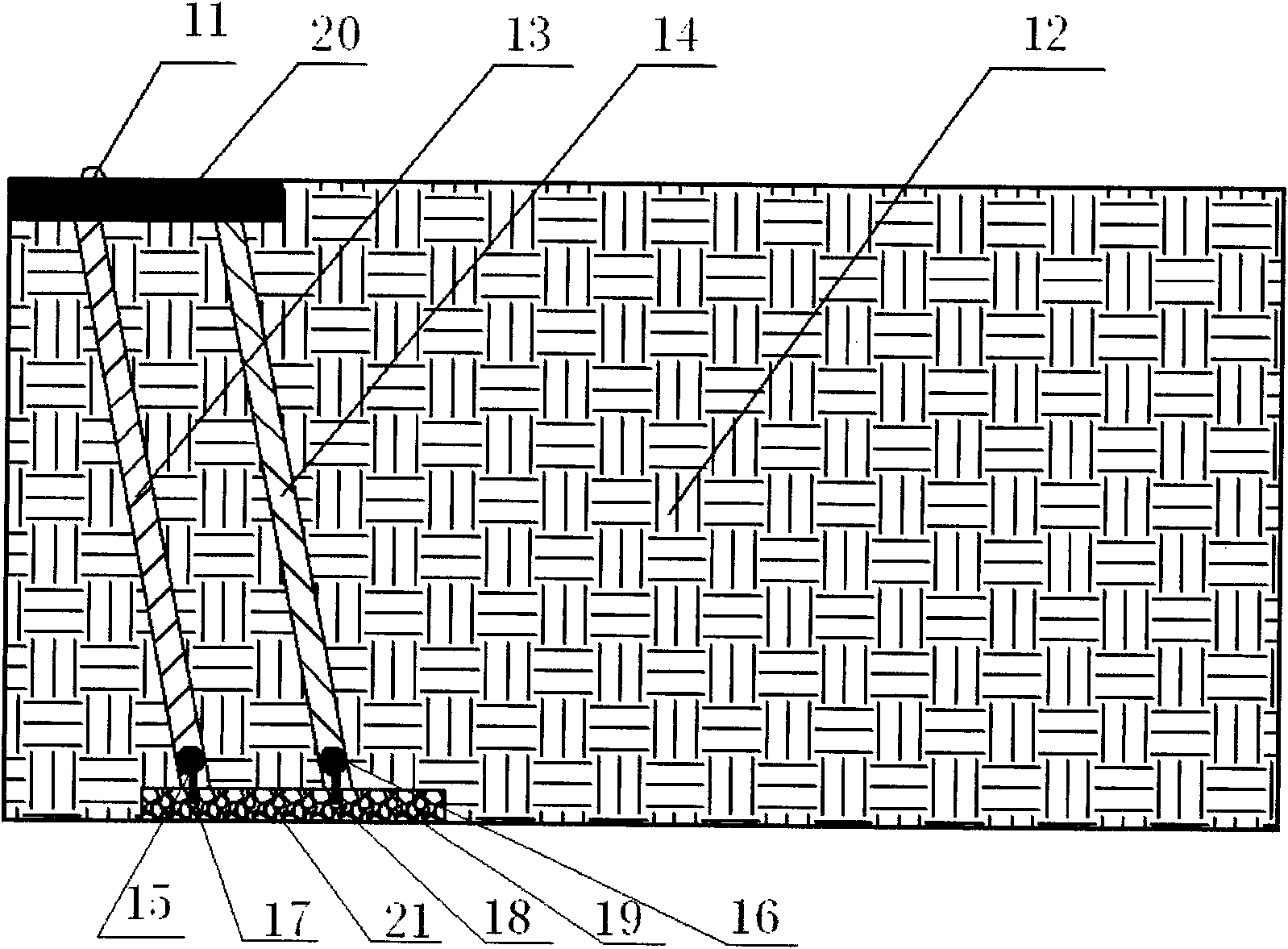

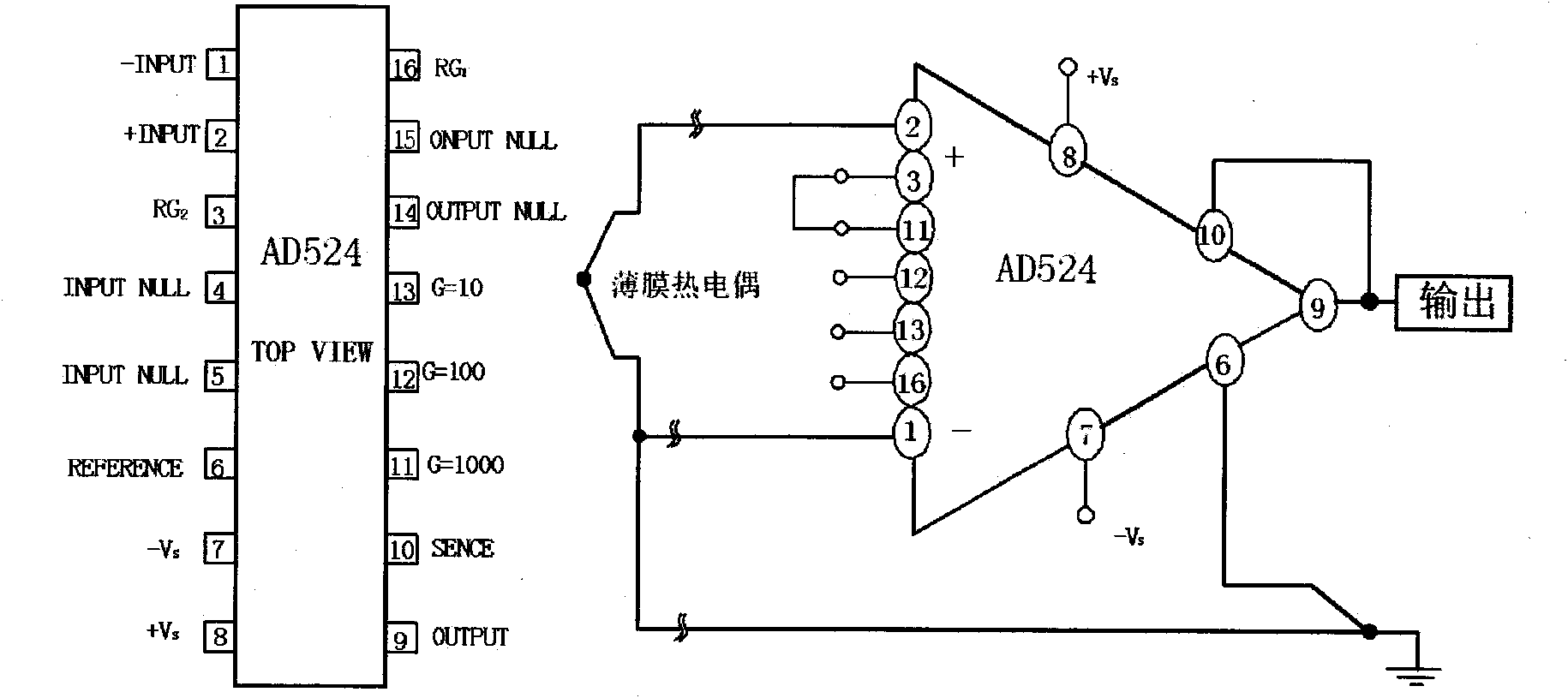

[0027] The present invention will be further described below in conjunction with the accompanying drawings. Such as figure 1 As shown, a system for dynamic calibration of thin-film thermocouples using lasers, including laser test bench target frame 2, continuous He-Ne laser 3, lens group 4, precision amplifier 8, DT9800 dynamic signal acquisition instrument 9, computer 10 and Test software, the laser light emitted by the continuous He-Ne laser 3 is irradiated to the thin-film thermocouple 1 installed on the target frame 2 of the laser test bench through the lens group 4, and the thin-film thermocouple 1 is sequentially connected with the precision amplifier through the data cable 8, DT9800 dynamic signal acquisition instrument 9 is connected with computer 10, and described test software is installed in computer 10, and described system also includes laser control power supply 5, Ultra-CFR short pulse laser 6 and frequency doubling crystal 7, described The laser control power...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Pulse width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com