Method for preparing organic-inorganic composite microspheres with eccentric structure

A technology of inorganic composite microspheres and eccentric structure, which can be used in the preparation of microspheres, microcapsule preparations, etc., and can solve the problems of naming and systematic research reports.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

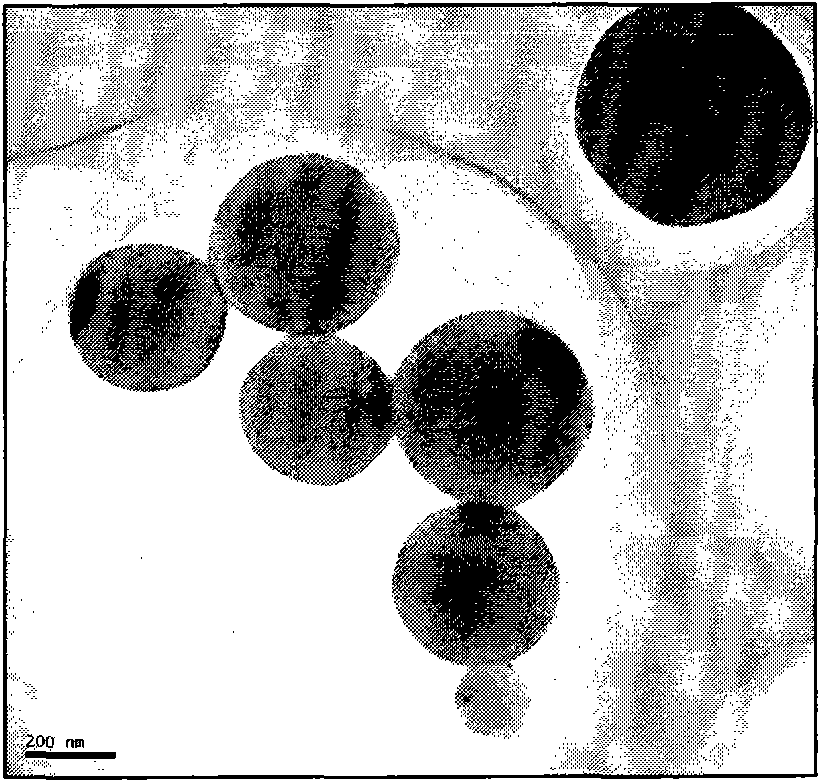

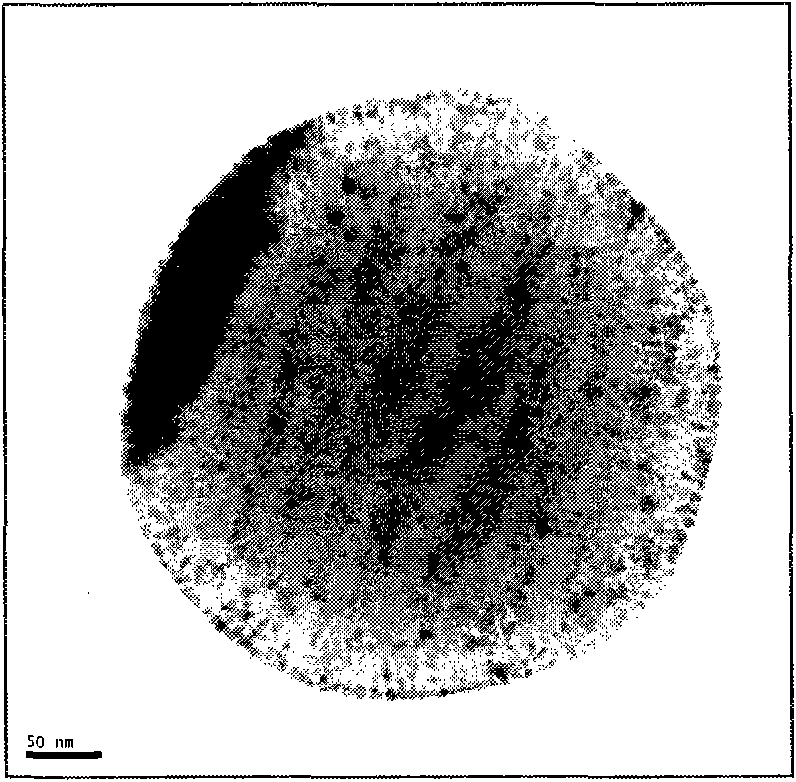

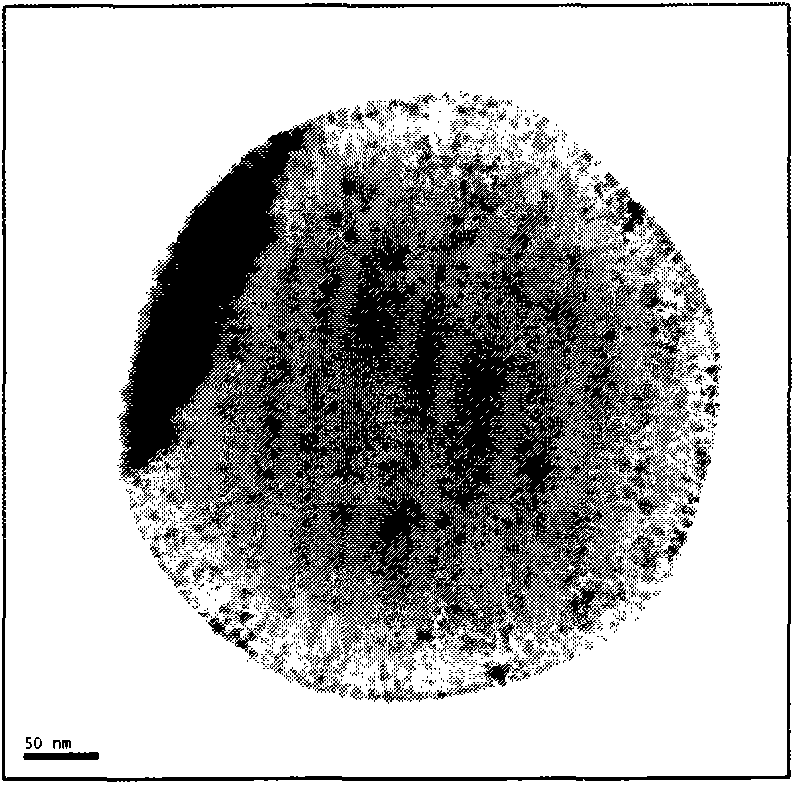

[0026] Example 1: Preparation of Magnetic Organic / Inorganic Composite Microspheres with Eccentric Structure by Miniemulsion Polymerization

[0027] Mix and disperse 5g of ferric oxide and 50g of distilled water, put it into a container equipped with an electric stirrer, a condenser tube and a thermometer, stir and raise the temperature of the system; when the temperature rises to 70°C, add 2g of oleic acid and keep it warm for 40 minutes ; After pouring out the water, use n-heptane as a dispersant to disperse, and prepare a suspension with a magnetic particle content of 10%; take the suspension and centrifuge it, remove the upper layer of n-heptane, and add styrene, Disperbyk- 106 and cetyl alcohol were prepared into an oil phase, wherein the mass-number ratio of suspension: styrene: Disperbyk-106: cetyl alcohol was 2: 20: 0.5: 1, and the oil phase was sonicated for 2 minutes to completely dissolve cetyl alcohol And the system is a macroscopic homogeneous phase; the water phas...

Embodiment 2

[0028] Example 2: Preparation of Magnetic Organic / Inorganic Composite Microspheres with Eccentric Structure by Miniemulsion Polymerization

[0029] Mix and disperse 5g of ferric oxide and 50g of distilled water, put it into a container equipped with an electric stirrer, a condenser and a thermometer, stir and raise the temperature of the system; when the temperature rises to 70°C, add 5g of oleic acid and keep it warm for 40 minutes ; After pouring out the water, use cyclohexane as a dispersant to disperse, and prepare a suspension with a magnetic particle content of 10%; after the suspension is centrifuged, remove the upper layer of cyclohexane, and add styrene, Disperbyk- 106 and cetyl alcohol were prepared into an oil phase, wherein the mass-number ratio of the suspension: styrene: Disperbyk-106: cetyl alcohol was 6: 20: 0.5: 0.5, and the oil phase was ultrasonicated for 5 minutes to completely dissolve the cetyl alcohol And the system is a macroscopic homogeneous phase; th...

Embodiment 3

[0030] Example 3: Preparation of Magnetic Organic / Inorganic Composite Microspheres with Eccentric Structure by Miniemulsion Polymerization

[0031] Mix and disperse 5g of ferric oxide and 50g of distilled water, put it into a container equipped with an electric stirrer, a condenser and a thermometer to stir and raise the temperature of the system; when the temperature rises to 80°C, add 4g of oleic acid and keep it warm for 30 minutes ; After pouring out the water, use cyclohexane as a dispersant to disperse, and prepare a suspension with a magnetic particle content of 10%; after the suspension is centrifuged, remove the upper layer of cyclohexane, and add styrene, Disperbyk- 106 and cetyl alcohol were prepared into an oil phase, wherein the suspension: styrene: Disperbyk-106: cetyl alcohol mass ratio was 10: 20: 1: 0.5, and the oil phase was ultrasonicated for 8 minutes to completely dissolve the cetyl alcohol And the system is a macroscopically homogeneous phase; the water p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com