Industrial preparation method of 5-methylpyrazin-2-amine

A technology of methylpyrazine and amino, which is applied in the field of industrial preparation of 2-amino-5-methylpyrazine, can solve problems such as inability to scale production and harsh reaction conditions, and achieve easy reaction, low preparation cost, and high reaction efficiency. Reasonable effect of process selection

Inactive Publication Date: 2010-10-13

SHANGHAI SYNTHEALL PHARM CO LTD +1

View PDF4 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The technical problem to be solved in the present invention is: solve the problem that the reaction conditions in the existing 2-amino-5-methylpyrazine preparation process are harsh and cannot be produced on a large scale; The industrialized preparation method of 2-amino-5-methylpyrazine

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

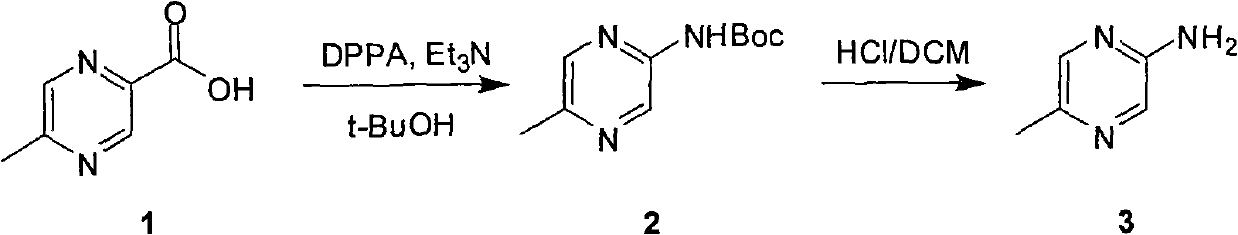

Login to View More Abstract

The invention relates to an industrial preparation method of 5-methylpyrazin-2-amine. In the invention, the 5-methylpyrazin-2-amine is prepared from general and easily obtained 5-methyl-2-pyrazinecarboxylic acid by the steps of azidation, Curtius rearrangement and Boc desorption. The chemical reaction formula is shown in the specification. The invention solves the problems of high cost, low yield, environment pollution and the like in the prior art, does not need column chromatography for purification, and can realize large-scale industrial production.

Description

Technical field: The invention relates to a preparation method of a 2-aminopyrazine drug intermediate, in particular to an industrial preparation method of 2-amino-5-methylpyrazine. Background technique: 2-Aminopyrazine compounds are relatively important drug intermediates, so the synthesis of such compounds has important application value. The 2-amino-5-methylpyrazine sold in the market is expensive, and there is still no industrial synthesis method for effectively preparing this product so far. The method for preparing 2-amino-5-methylpyrazine mainly contains following two kinds at present: method one, see literature synthetic route 1, take 5-methylpyrazine formic acid as raw material, first react with oxalyl chloride to obtain compound 6, then React with sodium azide to generate compound 7, then react with benzyl alcohol in situ to obtain Cbz-protected intermediate 8 through Curtius rearrangement, and finally obtain target compound 3 through Pd / C hydrogenation (Patent: ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C07D241/20

Inventor 曾伟付小普何大荣周盛峰郭劲松顾虹唐苏翰

Owner SHANGHAI SYNTHEALL PHARM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com