Support for turning over coiled steel

A technology of coiling steel and turning plate, applied in the field of flipping bracket, can solve the problems of insecurity, product deformation, occupation of manpower, etc., and achieve the effects of convenient operation, low loading and unloading cost, and safe and reliable loading and unloading.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

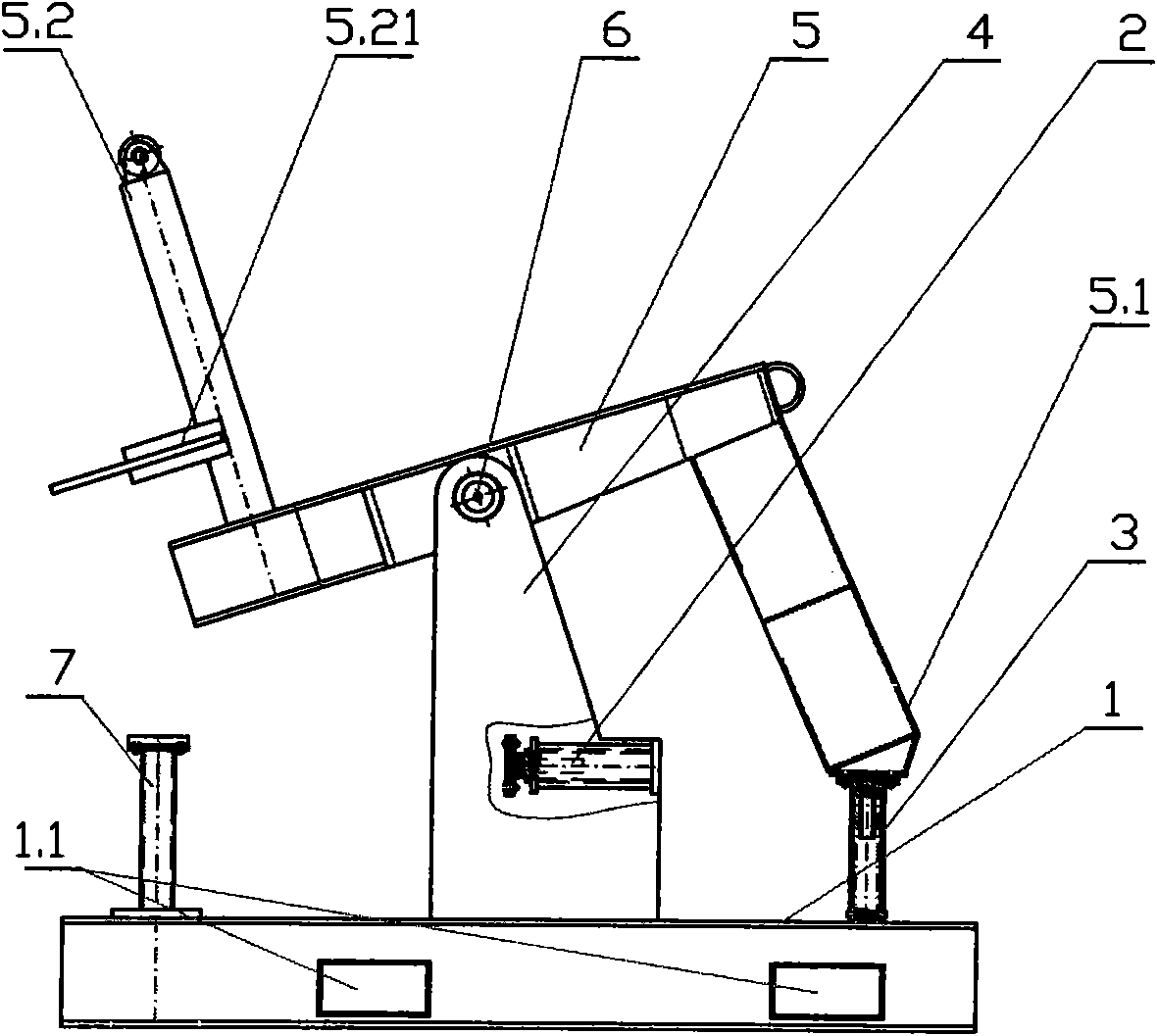

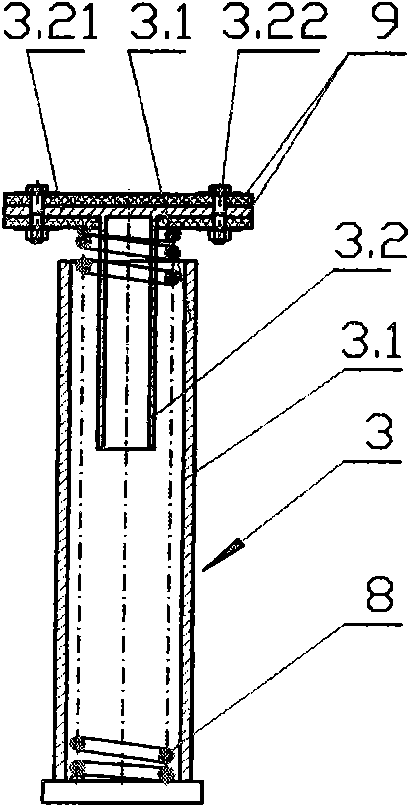

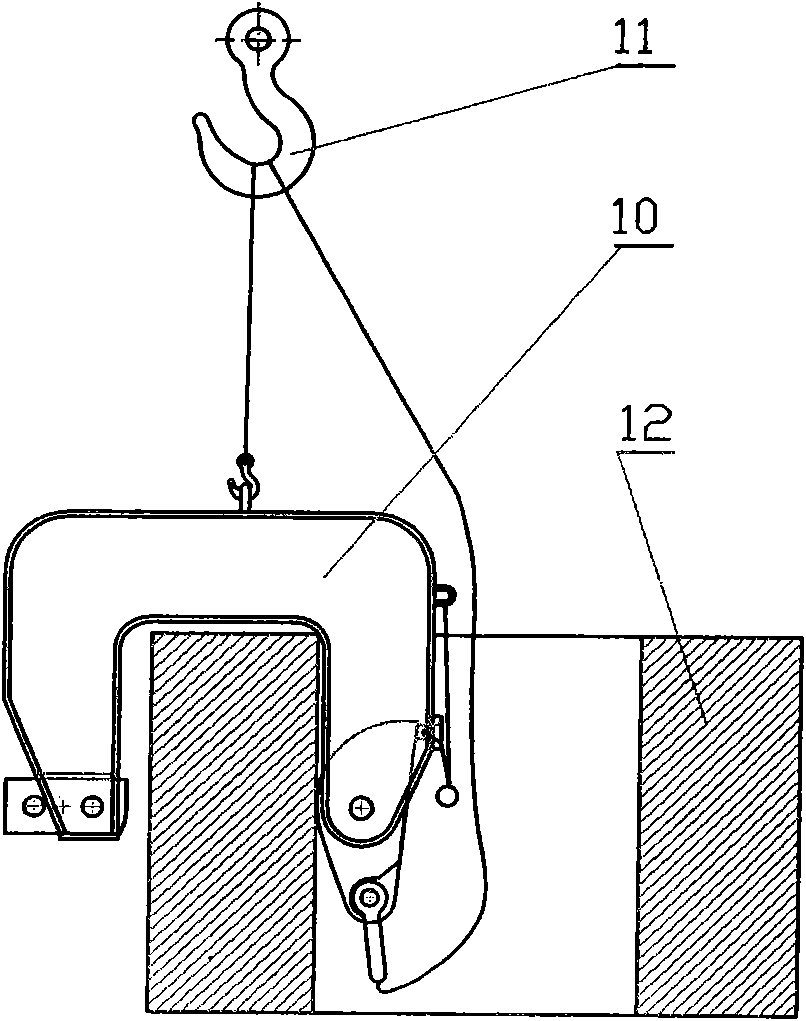

[0026] figure 1 Among them, a seesaw type flap 5 is supported on the base 1, and a support is fixed below the right end of the flap 5. The brace can make the inclination of the flap 5 above it when it is unloaded, which is the same as when the coil steel 12 is hoisted by a crane. , the inclination of the bottom surface of the steel coil 12 below the hook 11 is consistent, and the seesaw type flap 5 is in a balanced state at the same time; state, in the upright position (see Figure 5 , Image 6 ), can hold up the cantilever beam 5.2 of the coiled steel 12 in the prone position.

[0027] The support member fixed on the lower right side of the flap 5 is below the right end of the flap 5, and is vertically fixed with a counterweight box 5.1 with the flap 5, and the counterweight box 5.1 makes the flap 5 in a balanced state when it is unloaded;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com