Sputtering apparatus and sputtering film forming method

A sputtering and target technology, applied in the field of sputtering film formation, can solve problems such as low heat resistance, and achieve the effect of inhibiting the injection of hot electrons

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below, in conjunction with accompanying drawing, continue to describe the present invention, wherein, accompanying drawing shows the magnetron sputtering device (hereinafter referred to as coaxial type magnetron sputtering device) that uses cylindrical target material as a kind of embodiment of the present invention ).

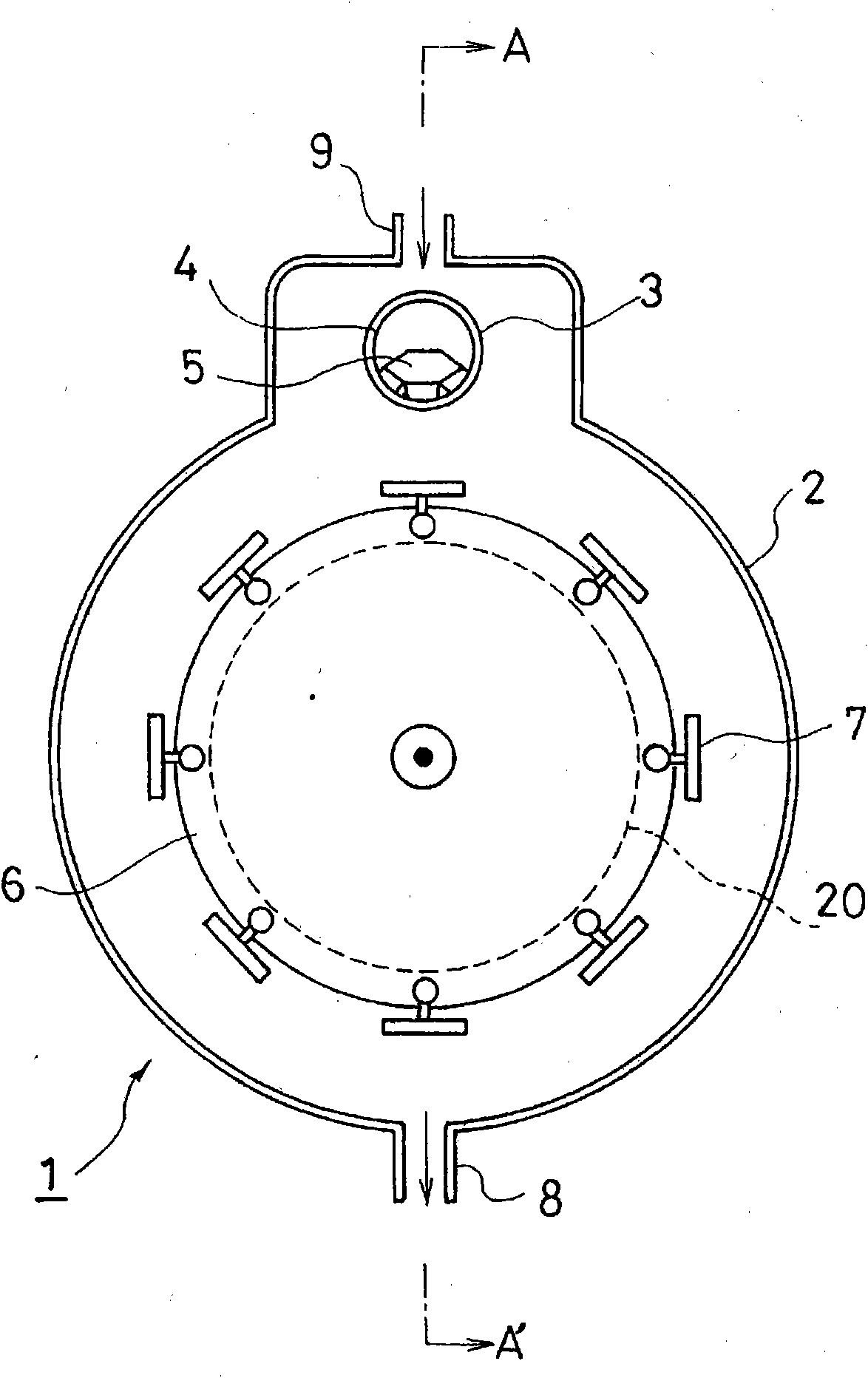

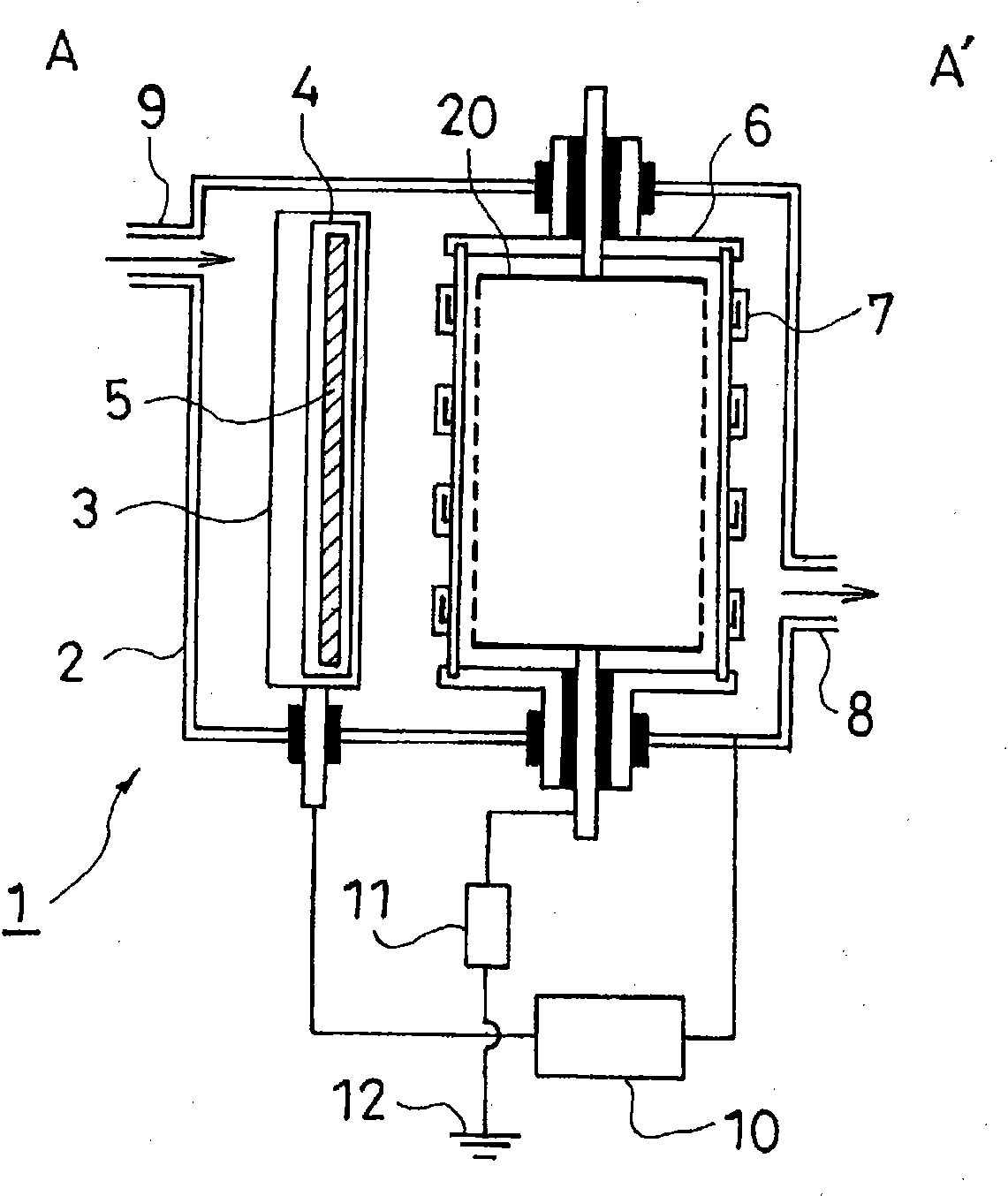

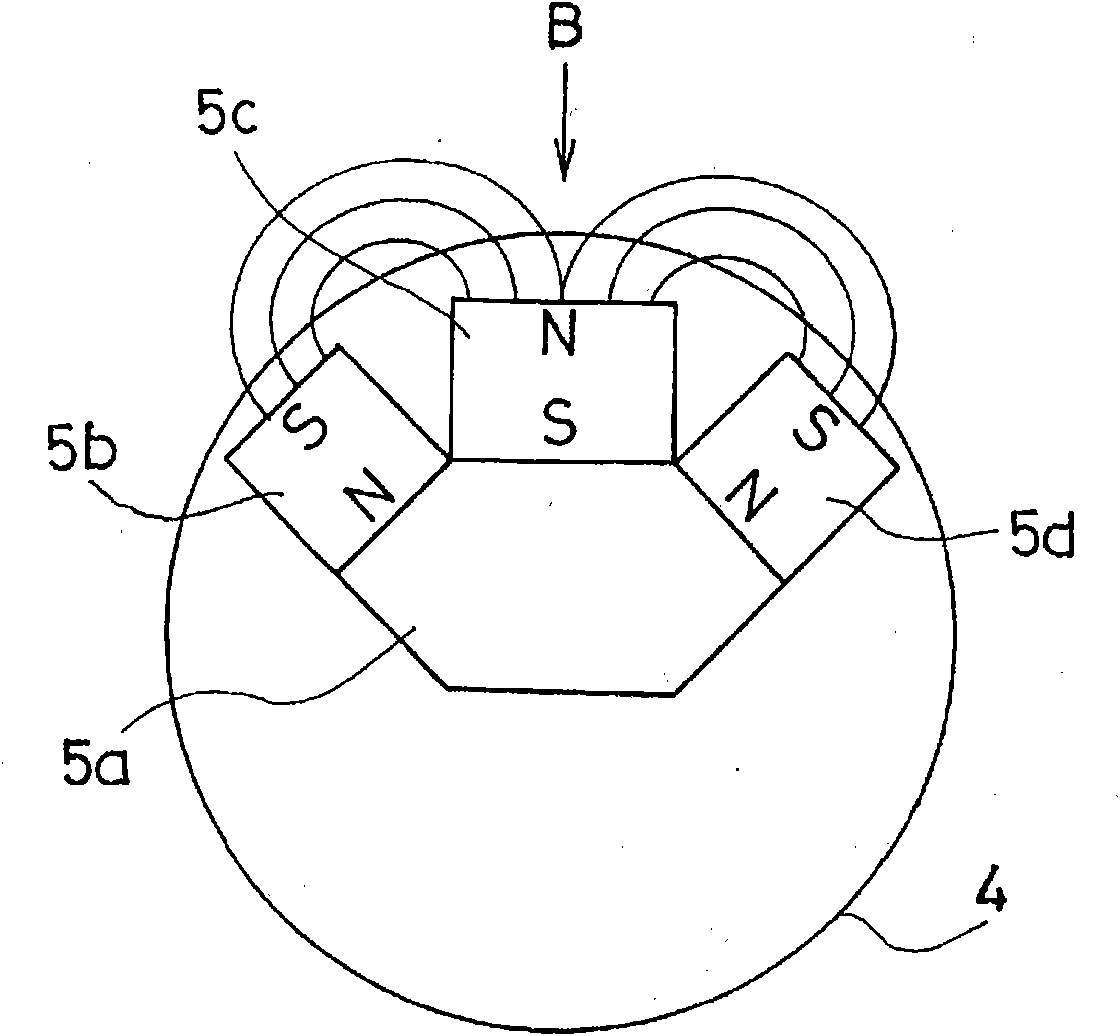

[0024] figure 1 It is a schematic diagram which schematically shows the main part of the coaxial type magnetron sputtering apparatus. In the figure, 1 denotes a coaxial magnetron sputtering device, 2 denotes a vacuum chamber, 3 denotes a cylindrical target, 4 denotes a magnet accommodating part, 5 denotes a target magnet, 6 denotes a turntable workpiece fixture, and 7 denotes a In the workpiece, 8 denotes an exhaust port, 9 denotes a gas inlet, and 20 denotes a thermal electron capture member.

[0025] and, figure 2 for figure 1 A-A' sectional view of . In the figure, the components denoted by numerals 1 to 9 and 20 are the same as those described...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com