Liner for vacuum sockets, and use of the liner

A vacuum cylinder and lining technology, applied in medical science, prosthesis, etc., can solve problems such as not considering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

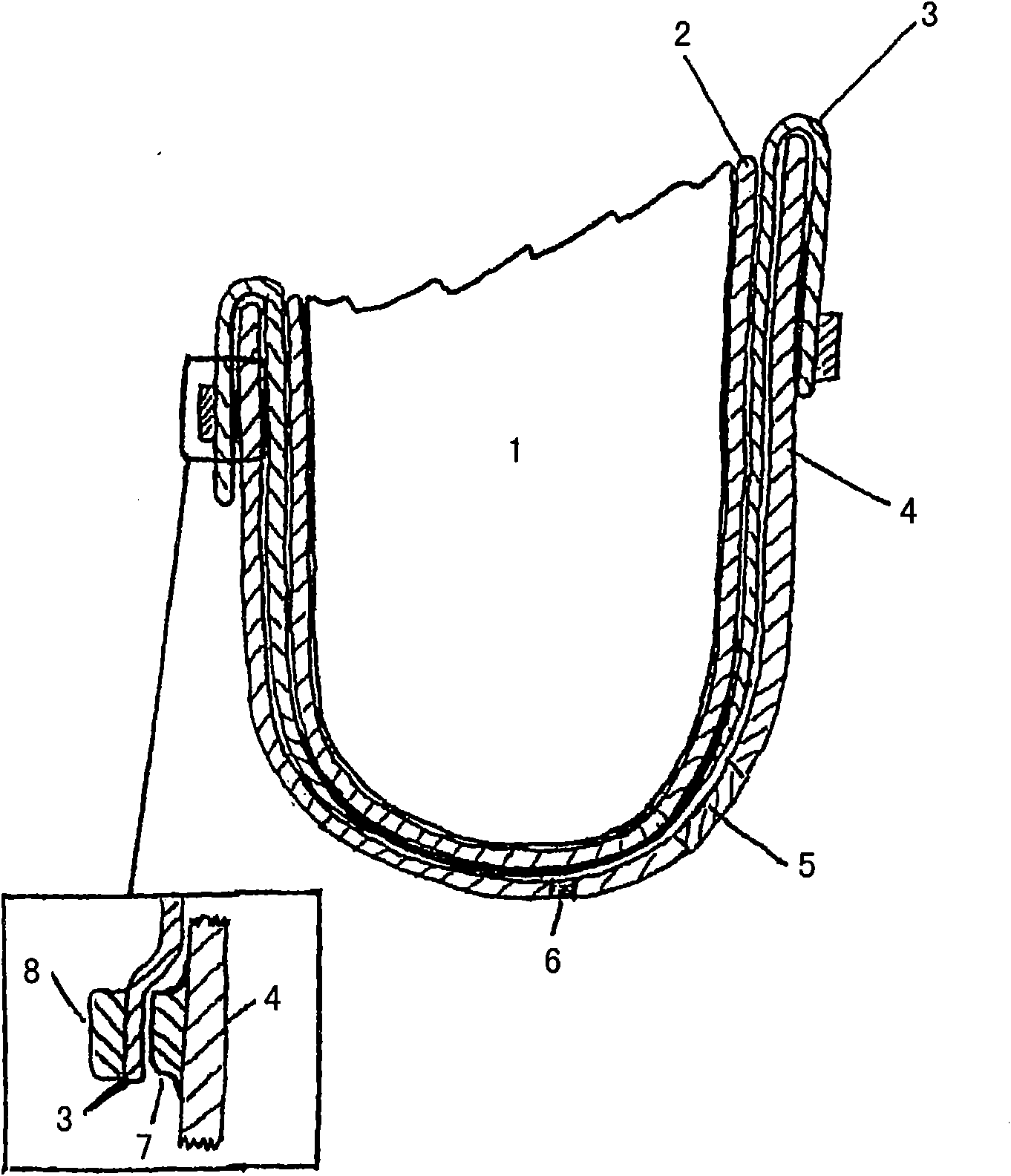

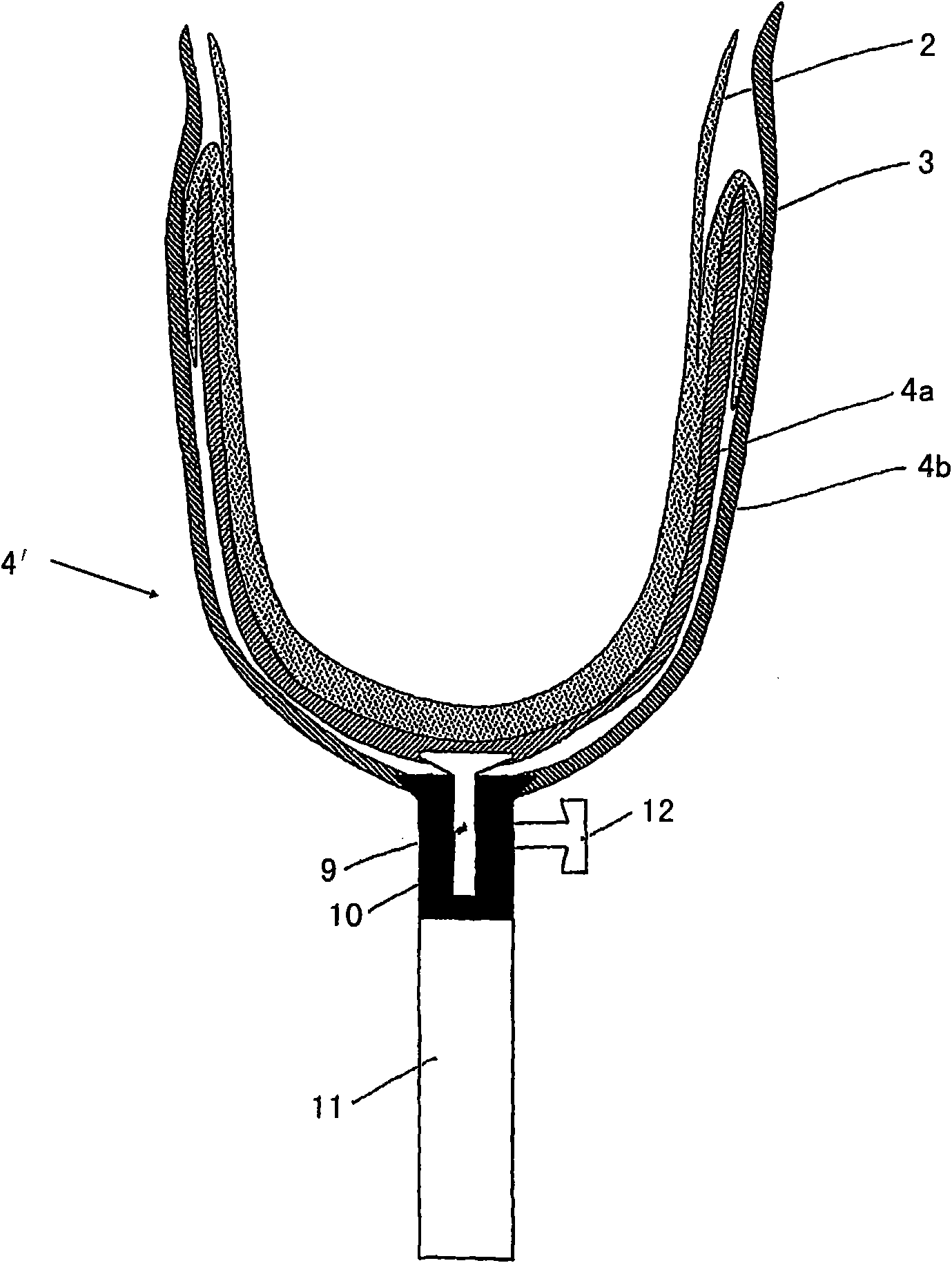

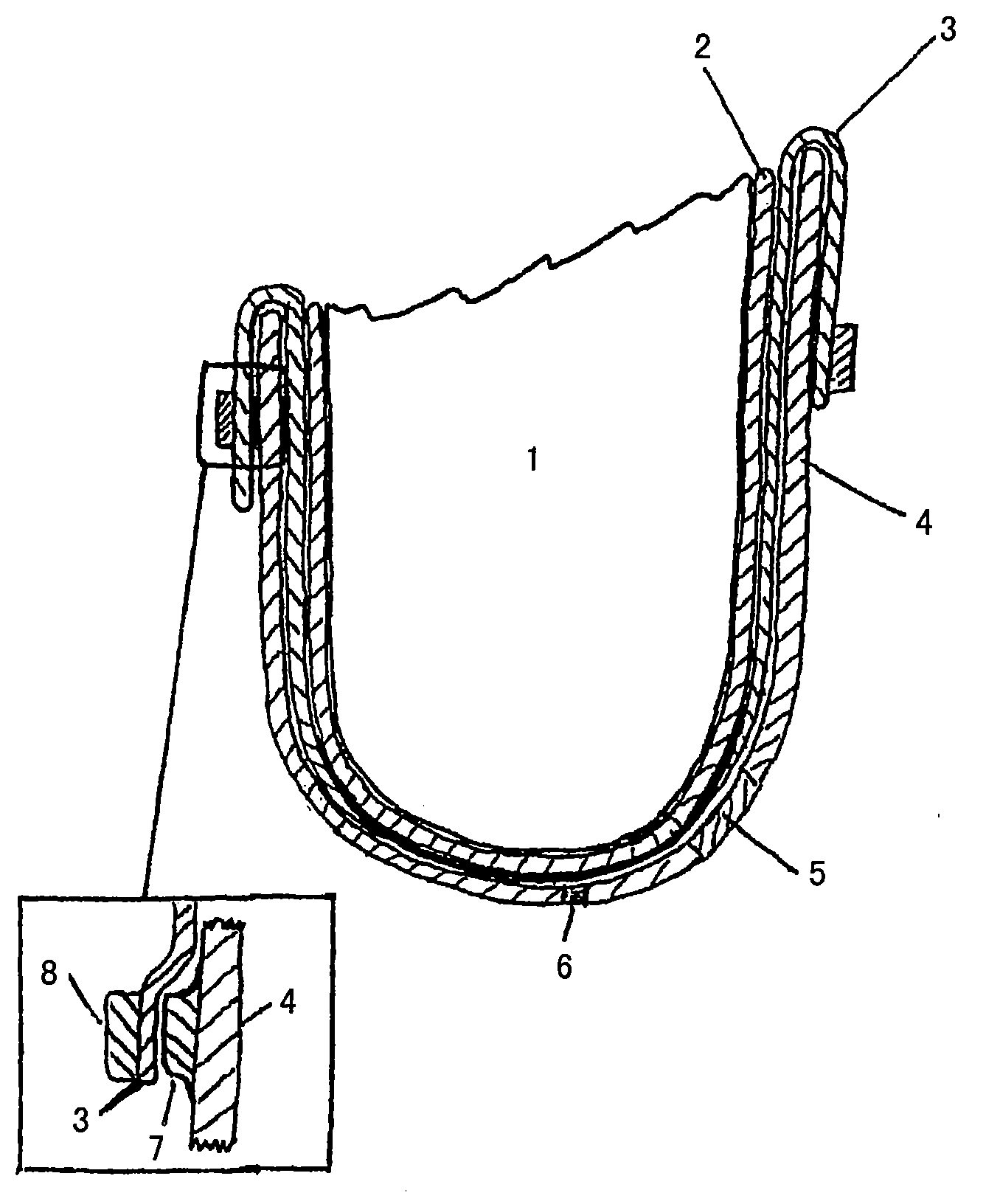

[0013] figure 1 The liner shown in comprises an inner liner 2 which is fixedly connected to the outer liner at the middle to the distal third, wherein the inner liner here also has a standard initial length. The liner can have a liner-specific distal shape by which longitudinal displacements are avoided, an individualized distal cup is used and which takes care of the necessary lateral expansion, etc.

[0014] To put the liner on, turn the complete liner inside out and roll the inner liner 2 over the stump. The individual mesial continuation of the edge of the inner lining can then be fixed and the inner lining shortened accordingly. The outer liner 3 is now folded proximally and the amputation stump 1 is inserted into the barrel 4 with the rolled up liner. The outer liner 3 is now folded distally onto the cartridge edge extension 4 and sealed on the outside of the cartridge 4 in order thereby to achieve a vacuum between the cartridge 4 and the linings 2 , 3 over the entire ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com