Circulating roller split bearing

A split, roller technology, applied in the direction of roller bearings, rolling contact bearings, bearings, etc., to achieve the effect of prolonging the service life, increasing the limit speed, and improving the bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

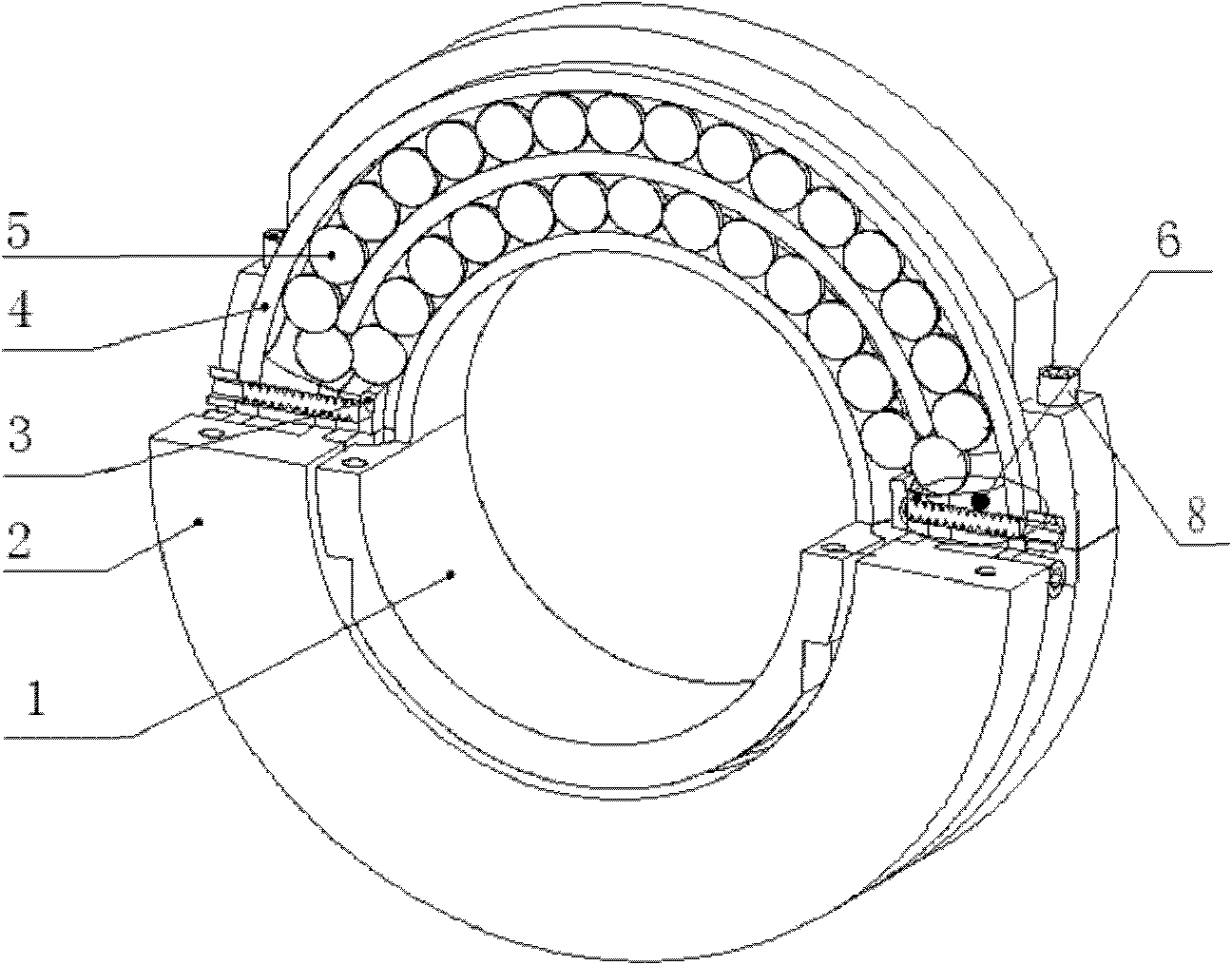

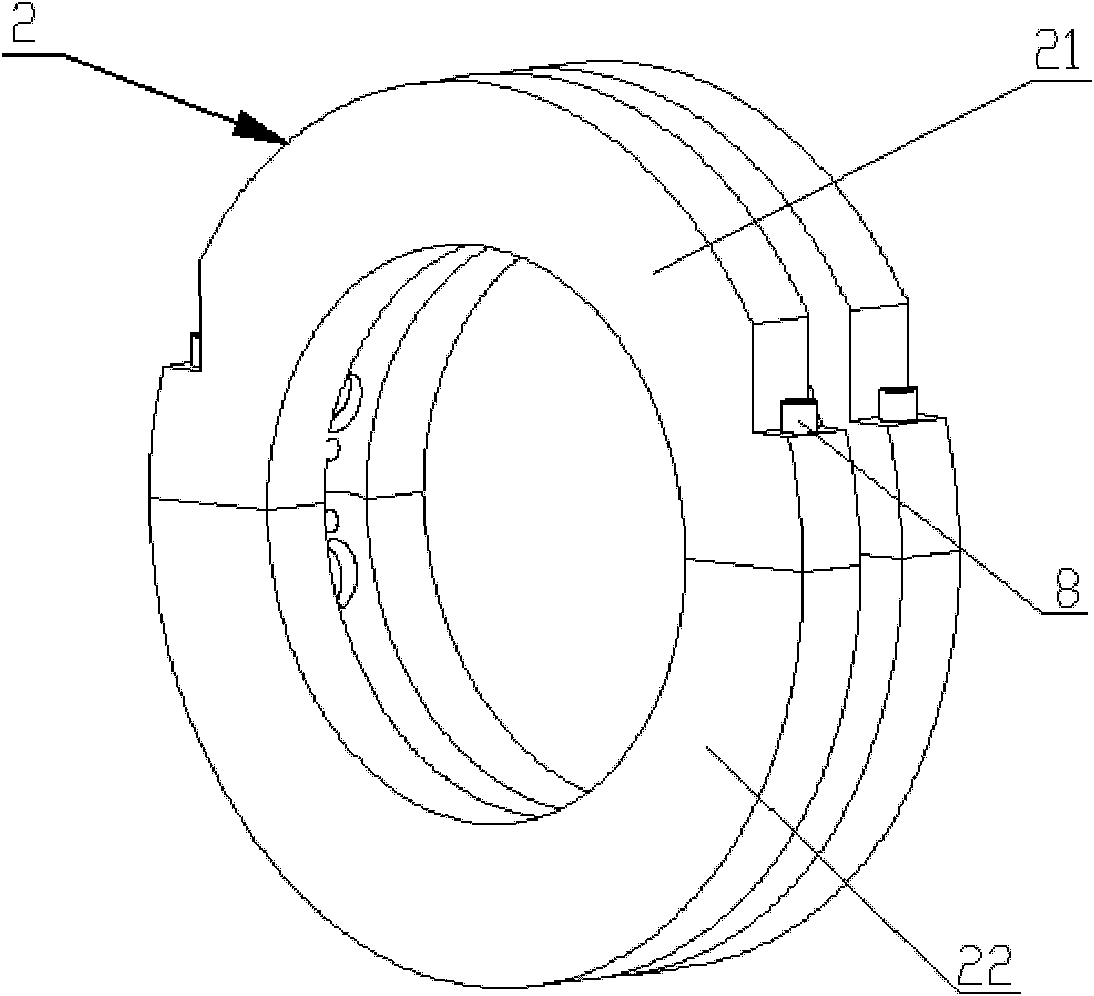

[0022] Markings in the attached drawings:

[0023] attached figure 1 , attached Image 6 , attached Figure 7 , attached Figure 10 , attached Figure 11 Middle, 1-inner ring, 2-bearing body, 3-inner retaining ring, 4-outer ring, 5-rolling element, 6-reverser, 7-reaming hole bolt, 8-reaming hole screw;

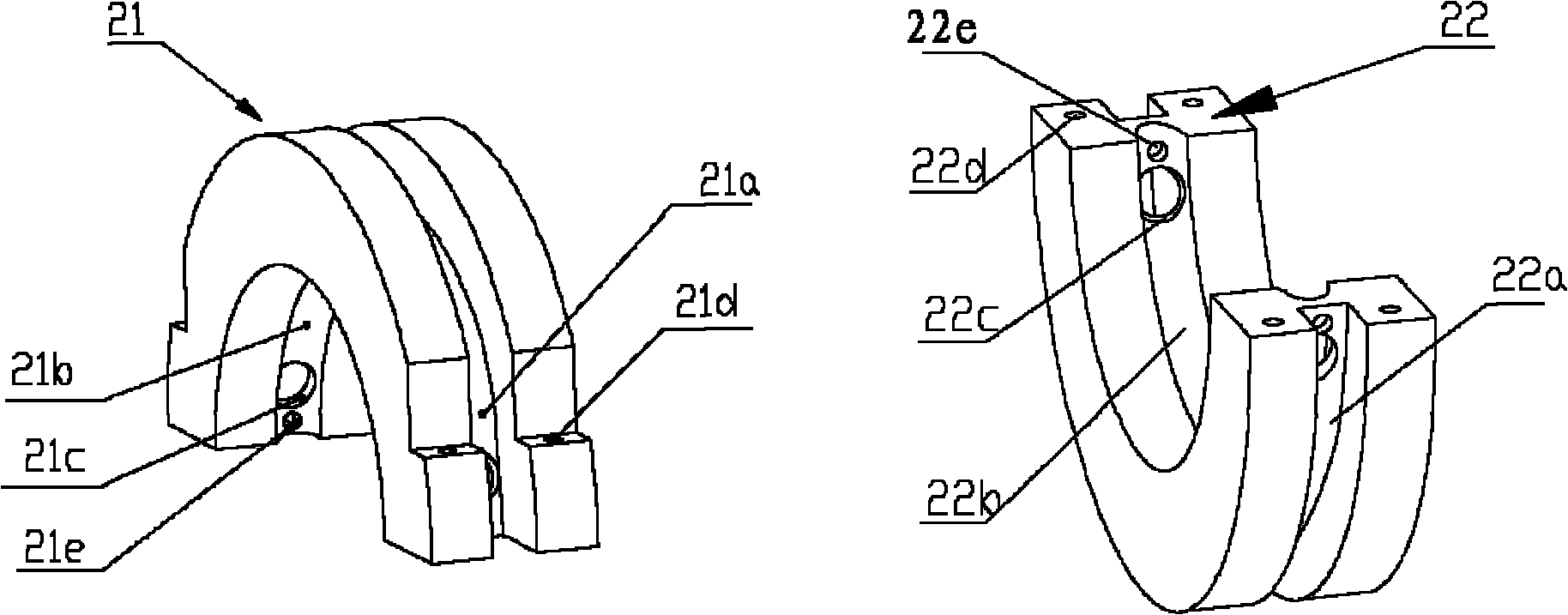

[0024] attached figure 2 , attached image 3 Among them, 21-upper part of bearing body, 21a-outer groove, 21b-inner groove, 21c-guide hole, 21d-reamed hole through hole, 21e-threaded through hole, 22-lower part of bearing body, 22a -Outer groove, 22b-inner groove, 22c-guide hole, 22d-reamed hole and internal threaded hole combination, 22e-threaded through hole;

[0025] attached Figure 4 , attached Figure 5 Among them, 11-upper part of inner ring 1, 11a-outer groove, 11b-through hole, 12-lower part of inner ring, 12a-outer groove, 12b-through hole;

[0026] attached Figure 8 , attached Figure 9 Among them, 61-screw, 62-outer stopper, 63-inner stopper.

[0027...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com