Method for improving and protecting collapsible loess slope project

A technology of collapsible loess and loess, which is applied in infrastructure engineering, excavation, construction, etc., can solve the problems that loess cannot meet the requirements of engineering strength and deformation, and achieve the effects of waste utilization, resource saving, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

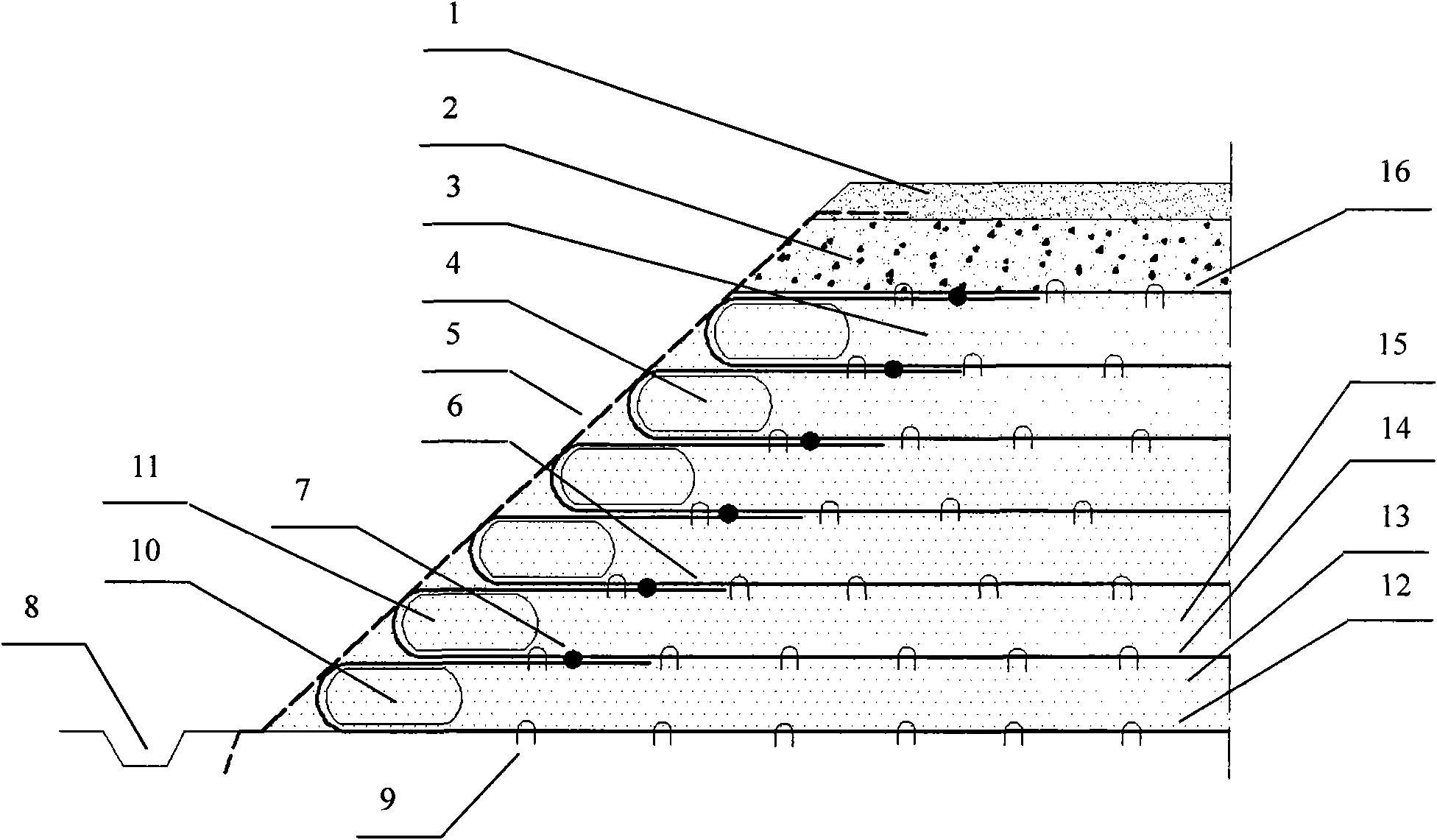

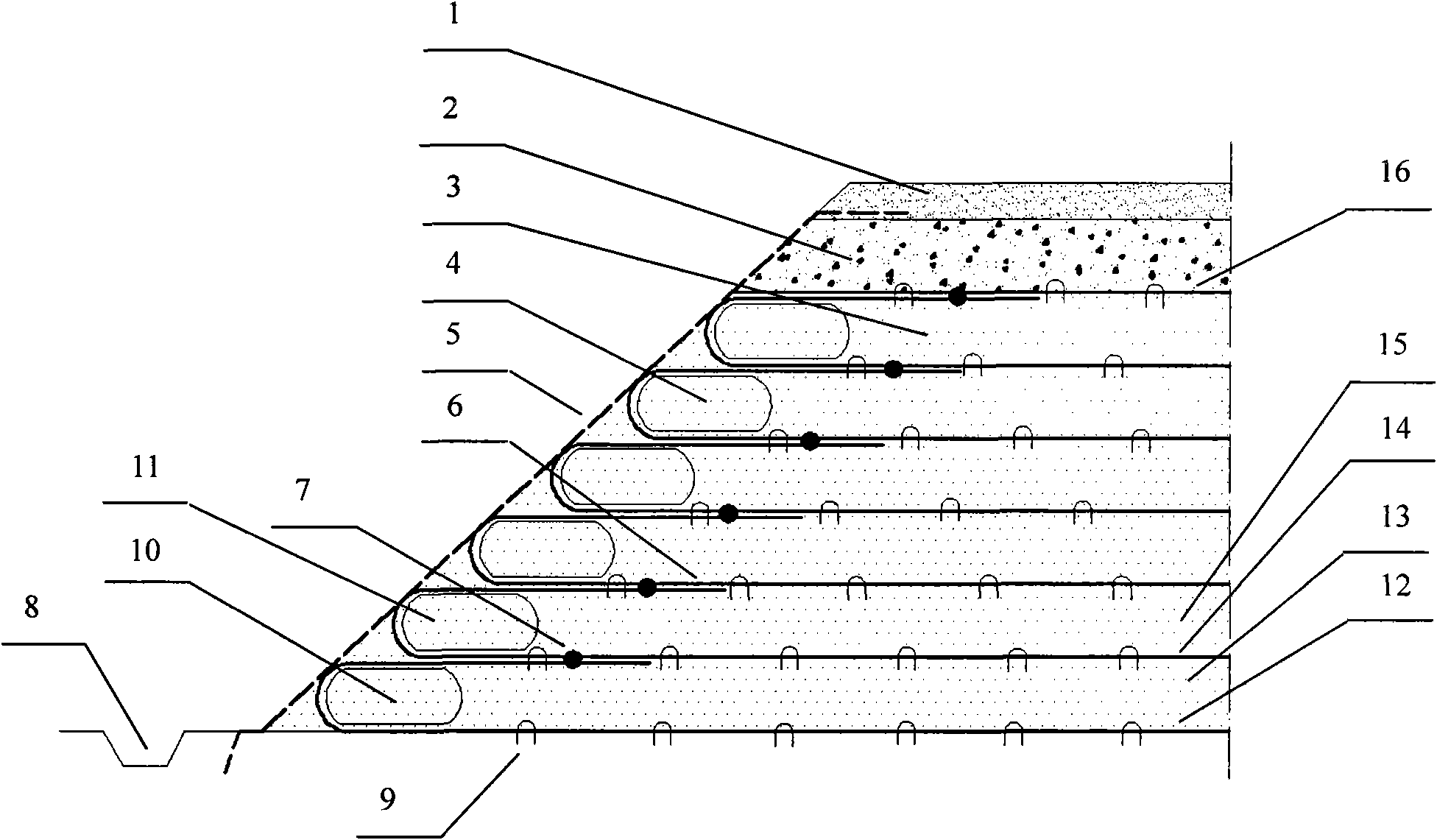

[0026] Embodiment: the method for improvement and protection of a certain collapsible loess slope engineering is as follows,

[0027] ① Level the site according to the requirements of the construction drawing, clear the floating soil and soft soil layer on the ground, remove the sewage on the ground, keep the ground dry and clean, lay the geogrid on the ground, and after laying level, use U-shaped steel bars to clamp into the soil and fix it;

[0028] ②According to the requirements of optimal water content and proportion, the lime fly ash improved loess should be blended and stirred. According to the construction drawings and site stakes, the sacks containing the improved loess and grass seeds should be placed at the foot of the slope. The short side is parallel to the filling direction, and then the improved loess is laid, the thickness is controlled within 30-50cm, and the required compaction is achieved by light rolling, and the first layer of rolling is completed;

[0029]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com