Novel foam-filled honeycomb sandwich board

A foam filling and sandwich panel technology, which is applied in the field of composite materials, can solve the problems of low shear strength and rigidity of foam sandwich panels, poor panel bonding performance, affecting popularization and application, etc., and achieves simple, convenient and cost-effective foam filling. Low, tear-resistant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with the accompanying drawings.

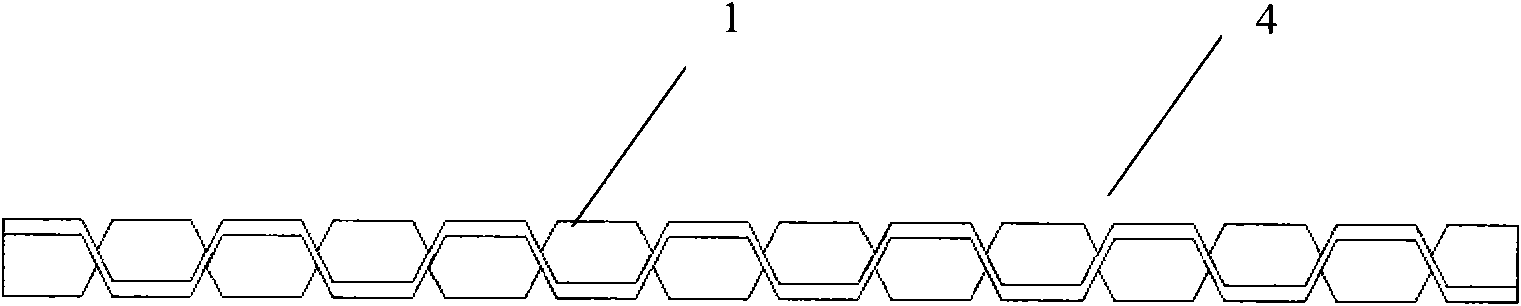

[0012] like Figure 4 As shown, a novel foam-filled honeycomb sandwich panel according to the present invention includes a pyramidal honeycomb core 3, panels 2 clamped on both sides thereof, and rigid polyurethane foam 5 filled by spraying or pouring. The panel 2 can be made of 1mm to 2mm metal material, such as industrial aluminum plate, stainless steel plate, steel plate, etc.; it can also be made of 1mm to 2mm non-metallic material such as plastic plate, glass steel plate, etc. The panels on both sides can be made of the same material, or any combination of dissimilar materials, which should be selected according to the requirements of use and the environment.

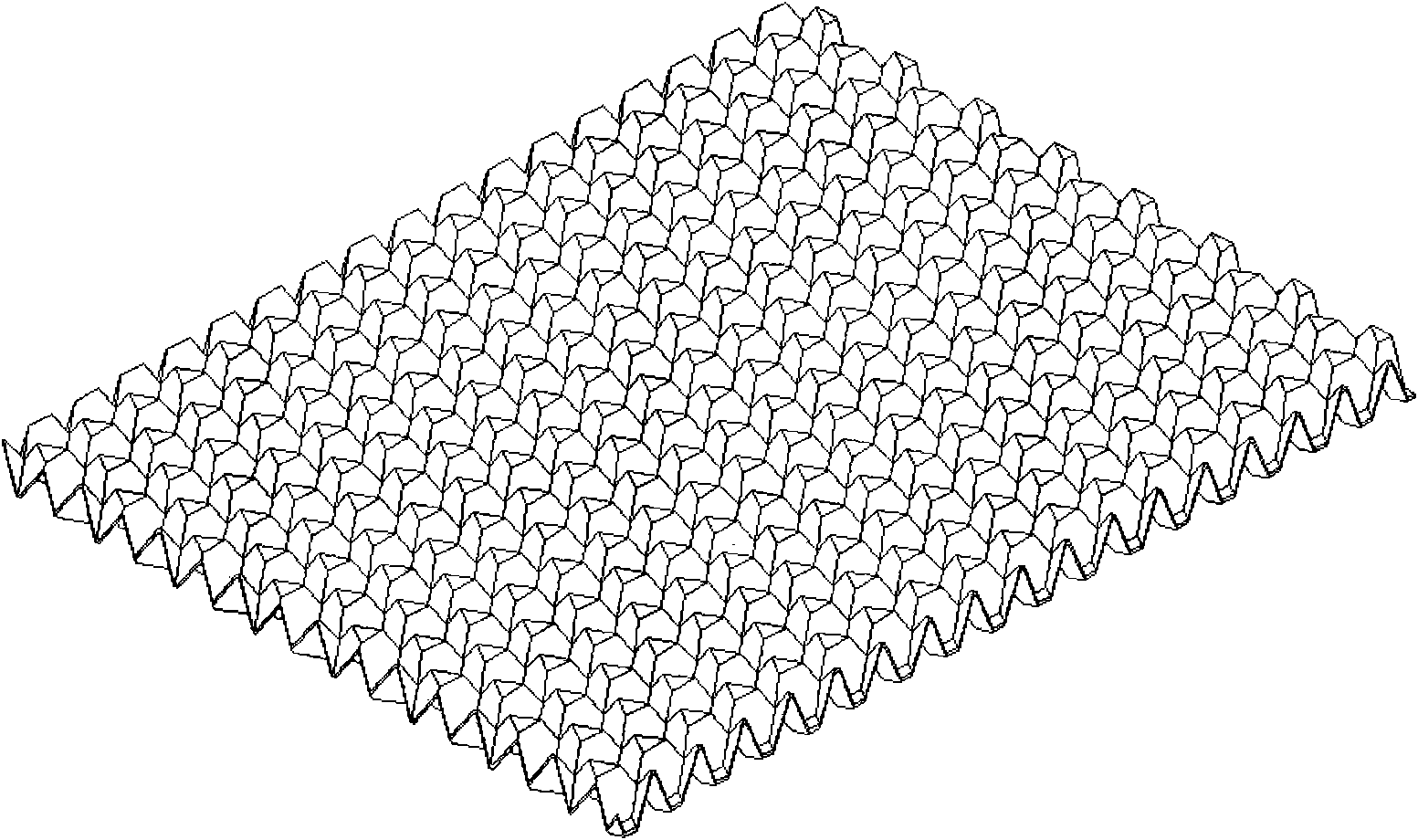

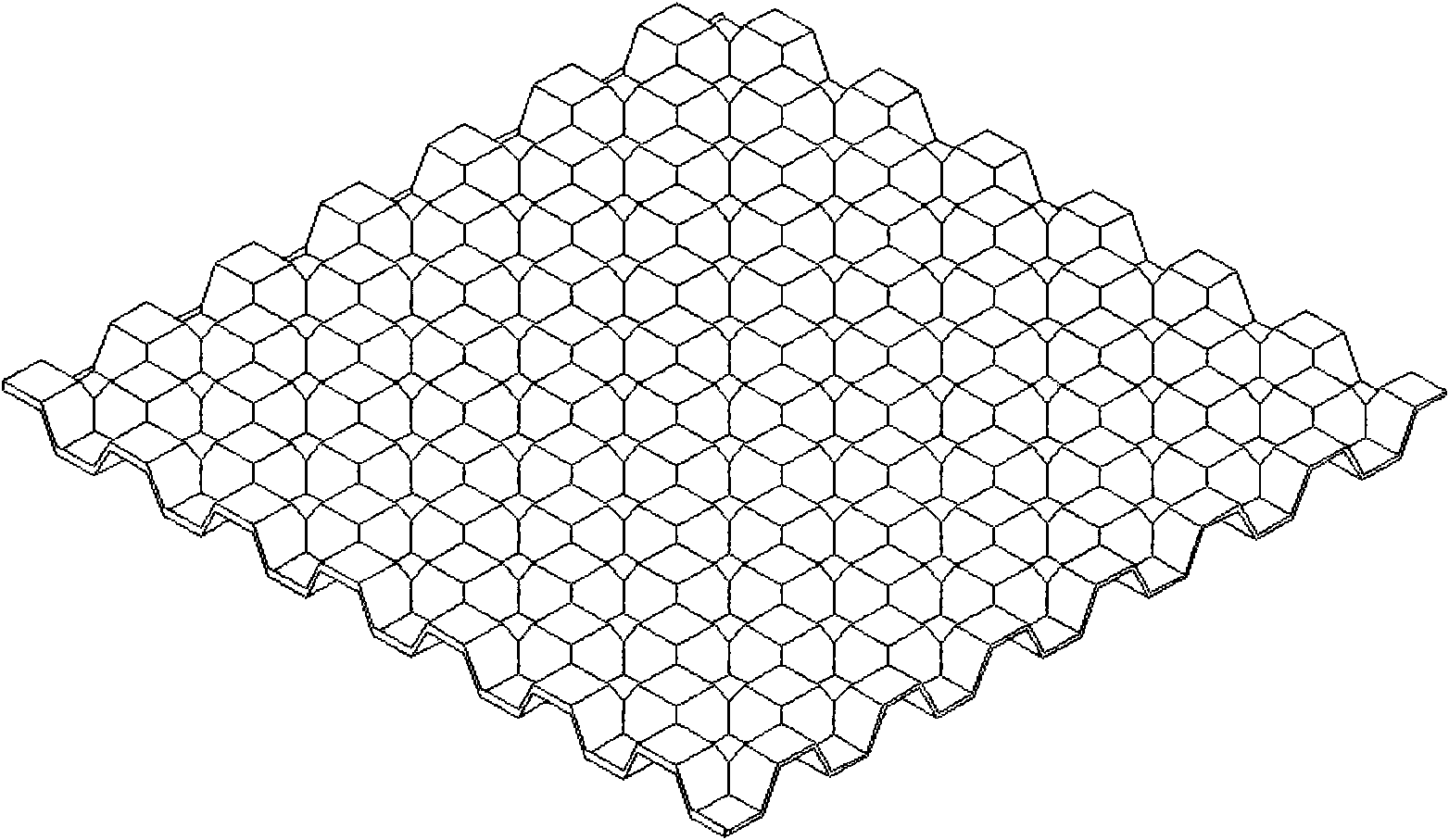

[0013] figure 1 , 2 As shown, the material prepared by the pyramidal honeycomb core 3 can be metal materials, such as industrial aluminum plates, stainless steel plates, steel plates, etc., or non-metalli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com