Low-noise humanoid robot head system

A low-noise, machine-based technology, applied in manipulators, manufacturing tools, etc., can solve problems such as difficult repeatability of human movements, high labor costs, and fatigue

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

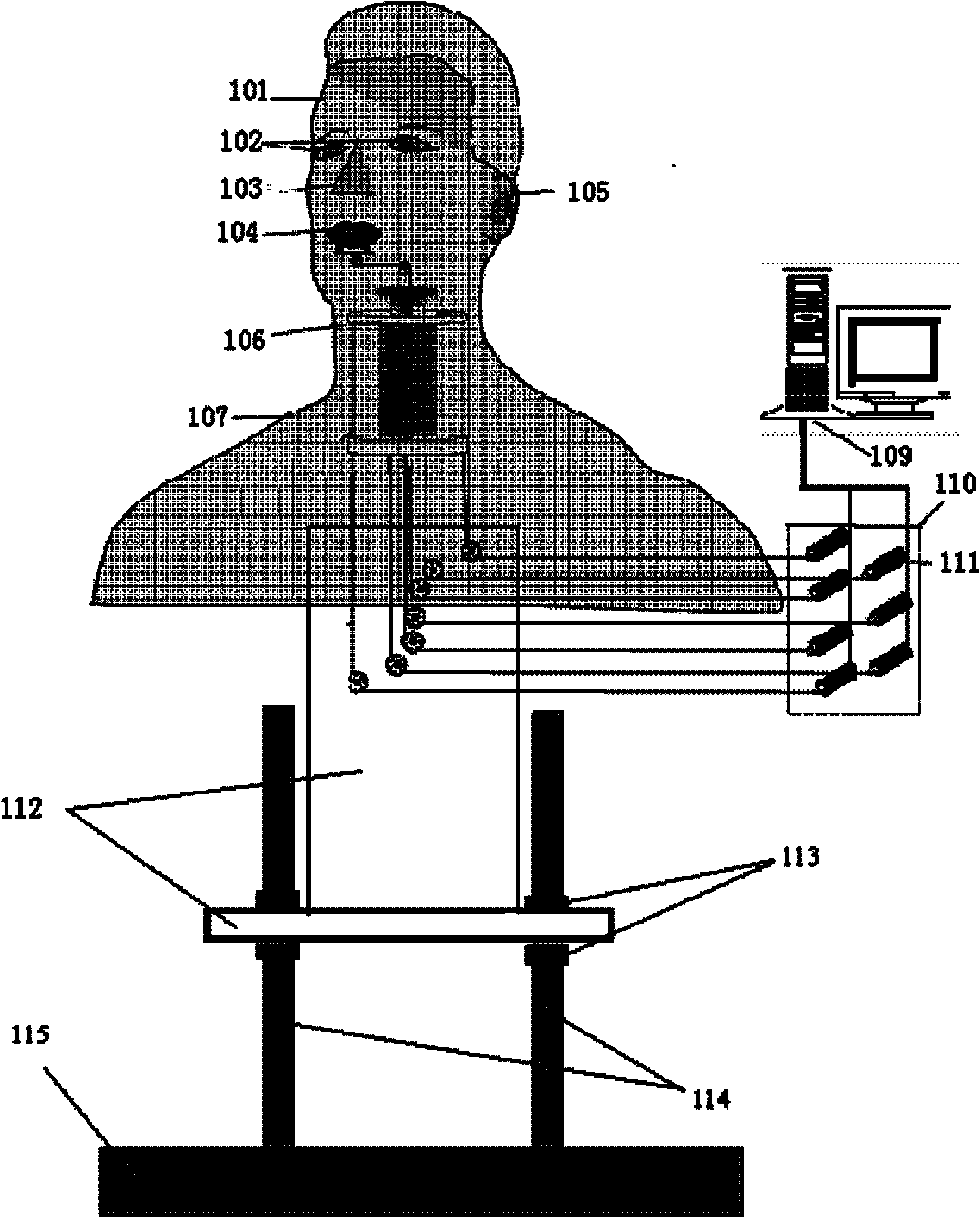

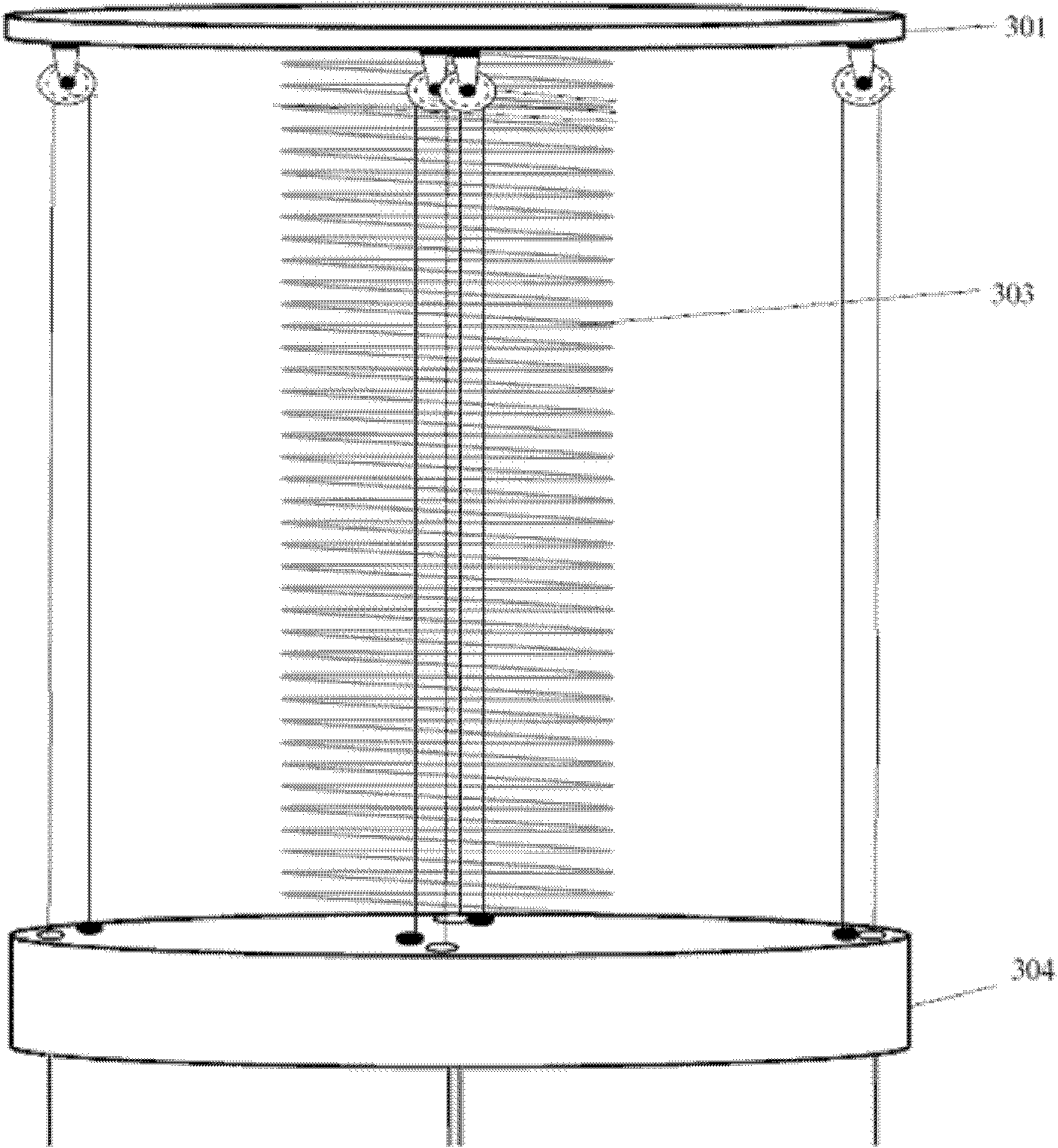

[0033] The humanoid robot head system in this example includes a humanoid upper body and a height-adjustable body support; the neck action driving part and the jaw action driving part are arranged in the humanoid upper body; the height-adjustable body support includes a base, four wires rod and a support connector used to connect the base and the upper body of the humanoid; one end of the screw is fixed to the base, the base and the support connector are connected and fixed through the screw, and the height is determined by the fixed position of the screw and the connector adjust.

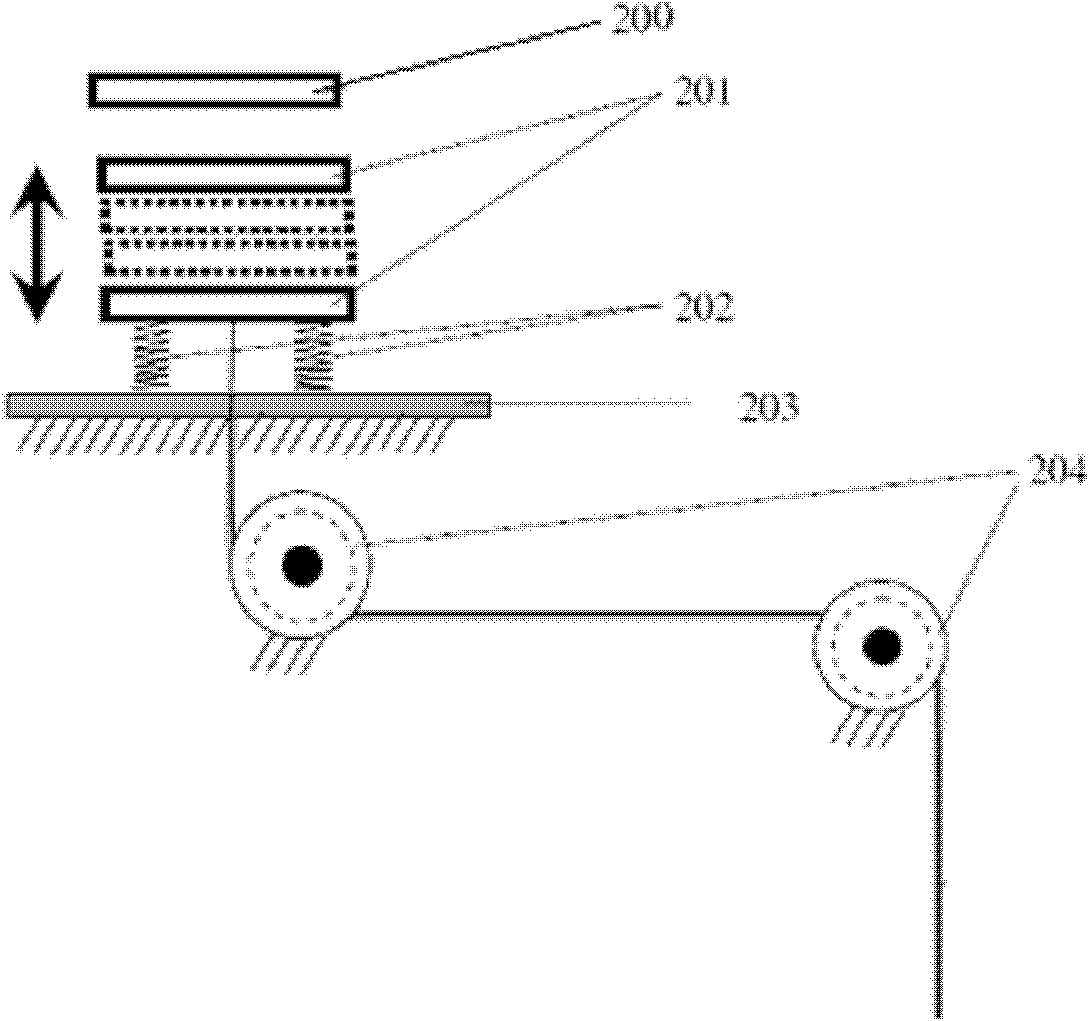

[0034] Such as figure 1As shown, the humanoid upper body 107 is provided with a humanoid head 101, two eyes 102, a nose 103, a mandibular action drive part 104 with one degree of freedom, two artificial ears 105, and a neck action drive with three degrees of free...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com