Irregular coin edge knurling device, edge knurling process and manufacturing method for edge knurling mould thereof

A hemming and special-shaped technology, which is applied in the manufacturing field of hemming molds, can solve the problems that the mold curve accuracy is difficult to meet the expected requirements, cannot ensure the correct phase of the blank, and rarely sees the hemming processing technology, etc., to achieve convenient and fast stand-alone High-volume manufacturing, ensuring correct phase, high-precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064]Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0065] In the best implementation mode of the present invention, the said special-shaped coin hemming equipment includes a cake conveying positioning device and a hemming device.

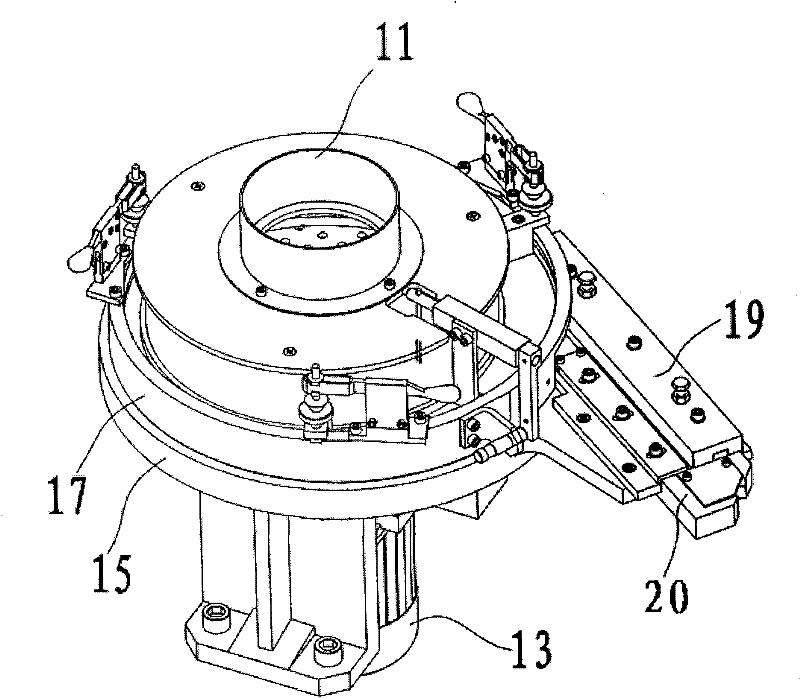

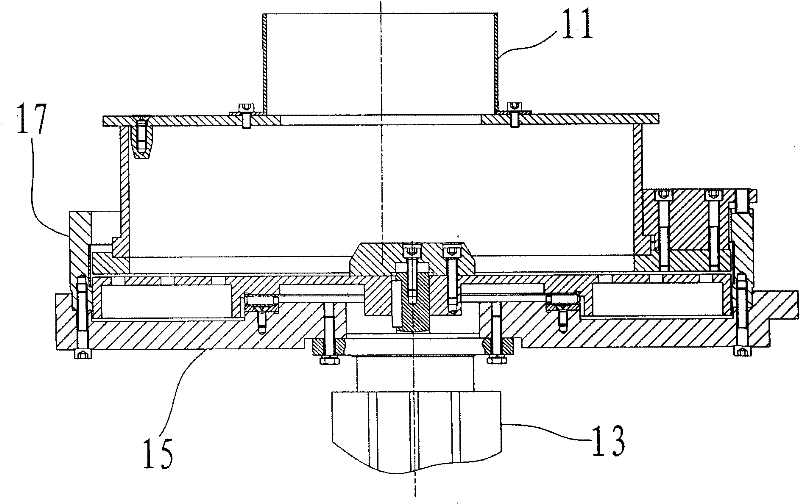

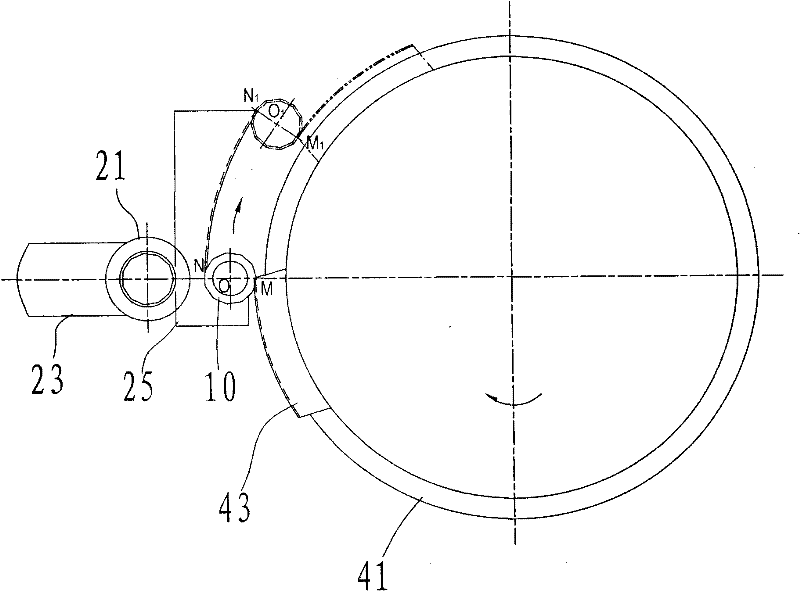

[0066] combine Figure 1 to Figure 4 As shown, the cake conveying positioning device includes a material inlet 11 arranged on the top of the cake conveying positioning device for blank cake input, a driving motor 13, which is arranged on the motor 13, and is connected with the motor 13 The rotating disk 15 with the same rotating shaft, and the connecting disk 17 sleeved in the rotating disk 15 and provided with a gap, preferably, the outer wall of the connecting disk 17 is set against the inner wall of the rotating disk 15, and the rotating disk 15 and the connecting disk 17 is provided with the screw that can adjust both relative heights, can be suitable for the flat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com