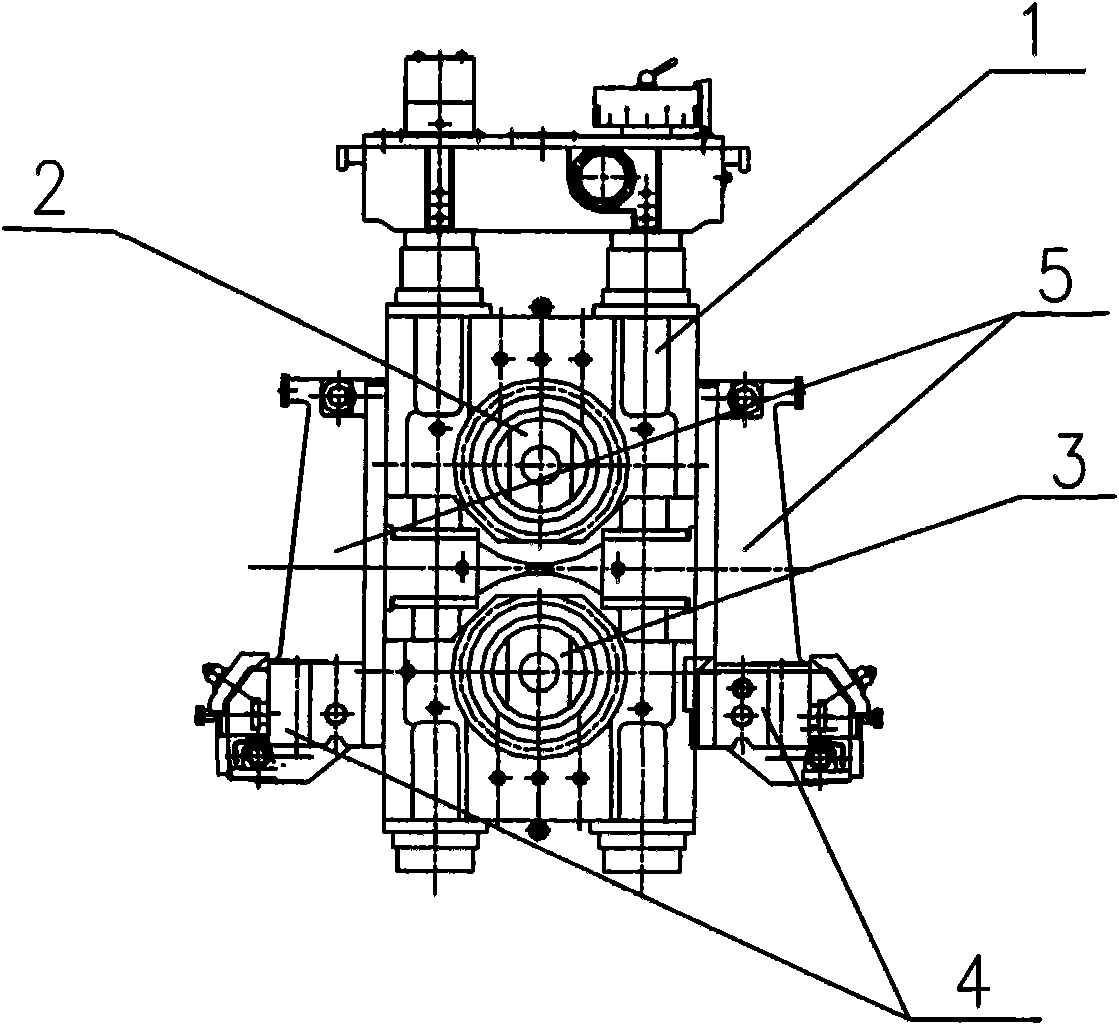

Guide crossbeam device for short stress bar rolling mill

A short-stress rolling mill and beam technology, applied in the direction of guiding/positioning/alignment devices, etc., can solve the problems of low slot change efficiency, high maintenance cost, and low slot change efficiency, and achieve long maintenance intervals and pollution resistance Good, low maintenance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

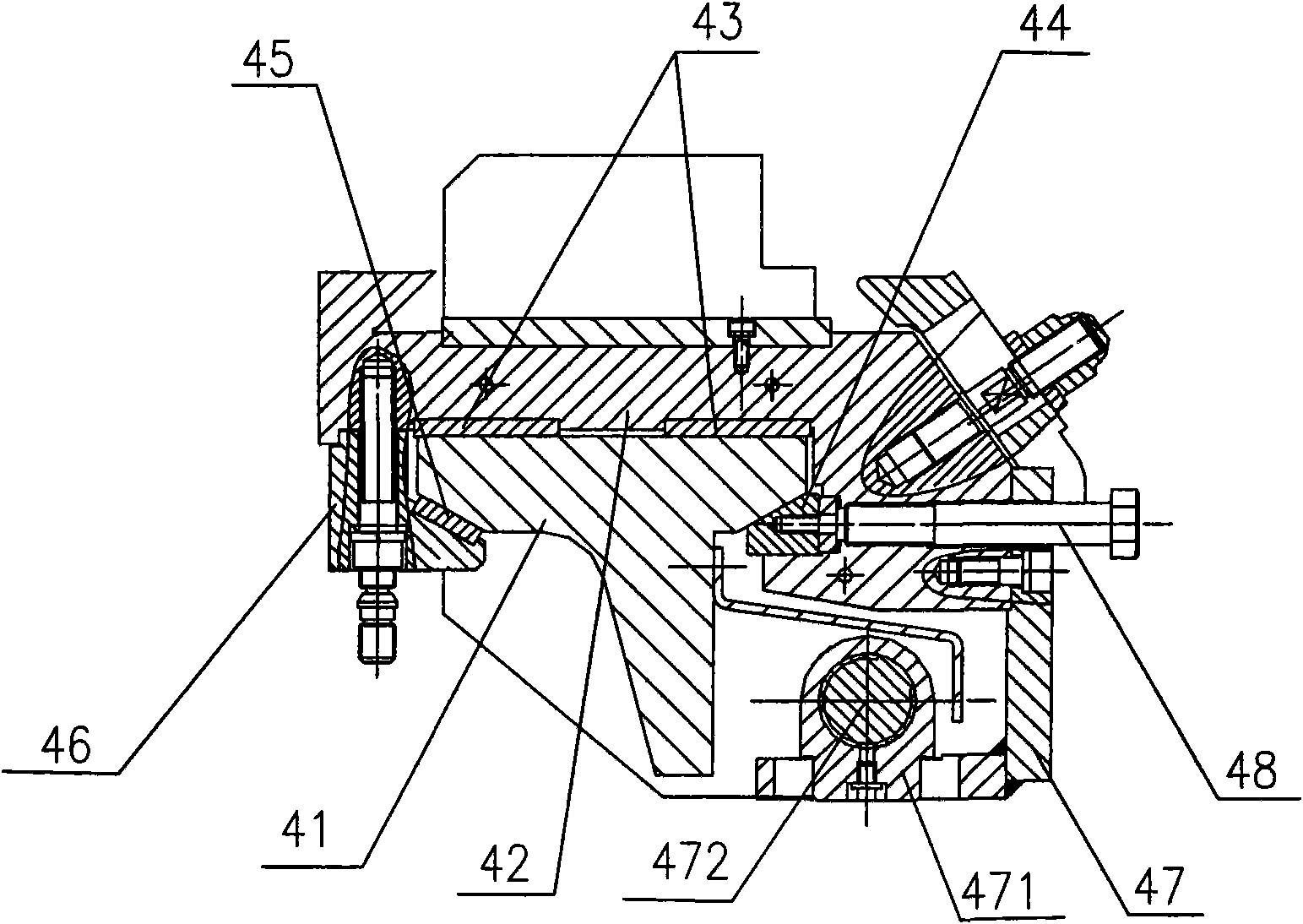

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, but these embodiments should not be construed as limiting the present invention.

[0040] see Figure 4 and Figure 5 , the present invention is a kind of guiding and guarding crossbeam device that is used for bar short-stress rolling mill, comprises guiding and guarding beam body 41, guiding and defending seat 42, lower pressure plate 46, upper slope polytetrafluoroethylene backing plate 8, lower plane polytetrafluoroethylene Backing plate 9, worm gear rack 10, worm screw 12, worm gear bearing seat 11, locking screw rod 48, slag flushing slope 15, wherein, guide guard crossbeam body 41 is made up of left guide rail 6, right guide rail 7, worm gear rack fixed mount 13 and Rib 14 forms, and left guide rail 6 and right guide rail 7 are all positioned at the top of worm gear rack fixed mount 13, and these three are all fixed on rib 14.

[0041] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com