Aspermous orange environment-friendly processing method

A seedless citrus and production method technology, applied in the direction of food science, etc., can solve the problems of increasing extra expenses and expenses, reducing debittering efficiency, poor debittering effect, etc., to achieve cost saving and cost saving, broad consumer market, and diverse varieties Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

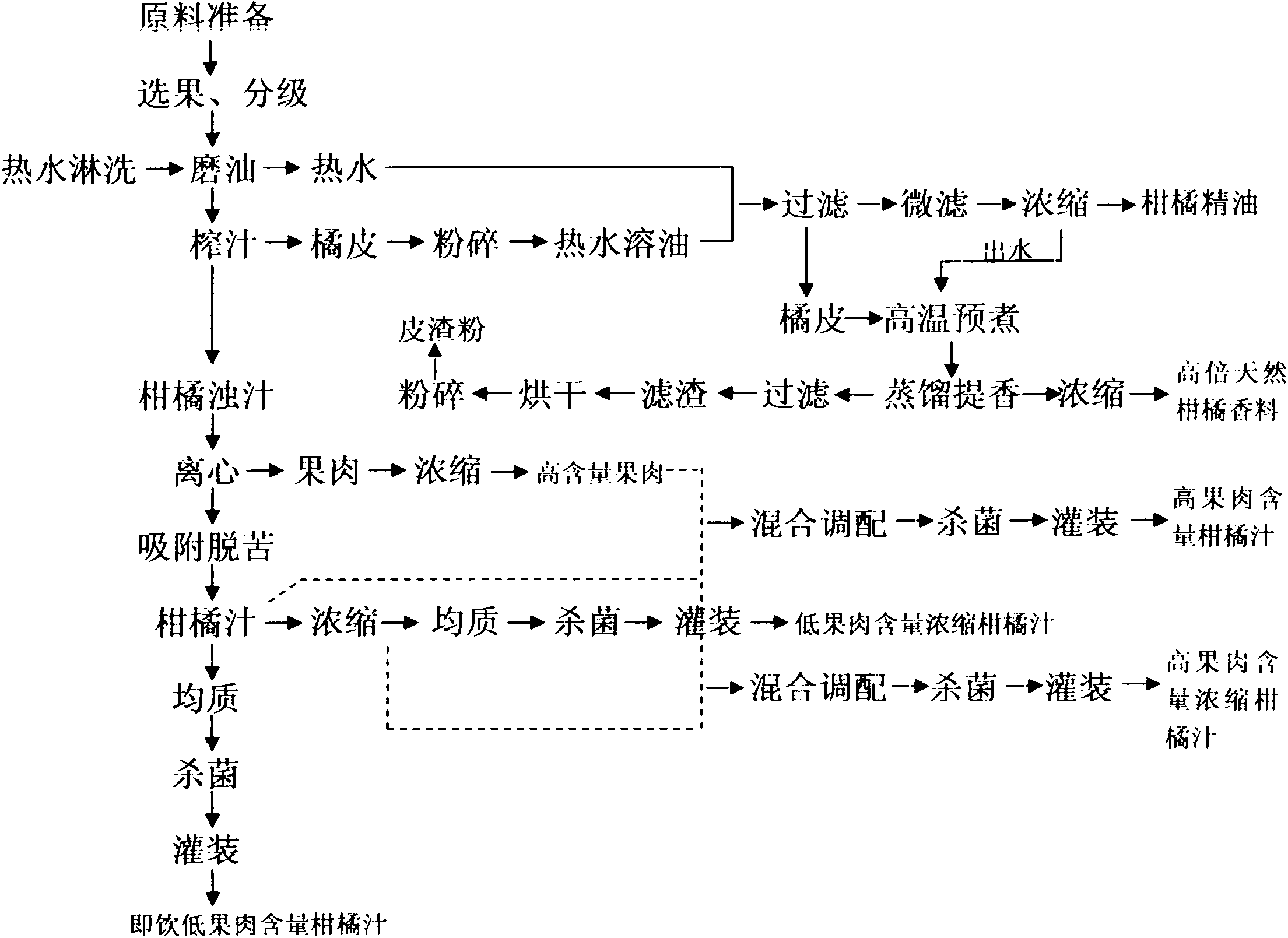

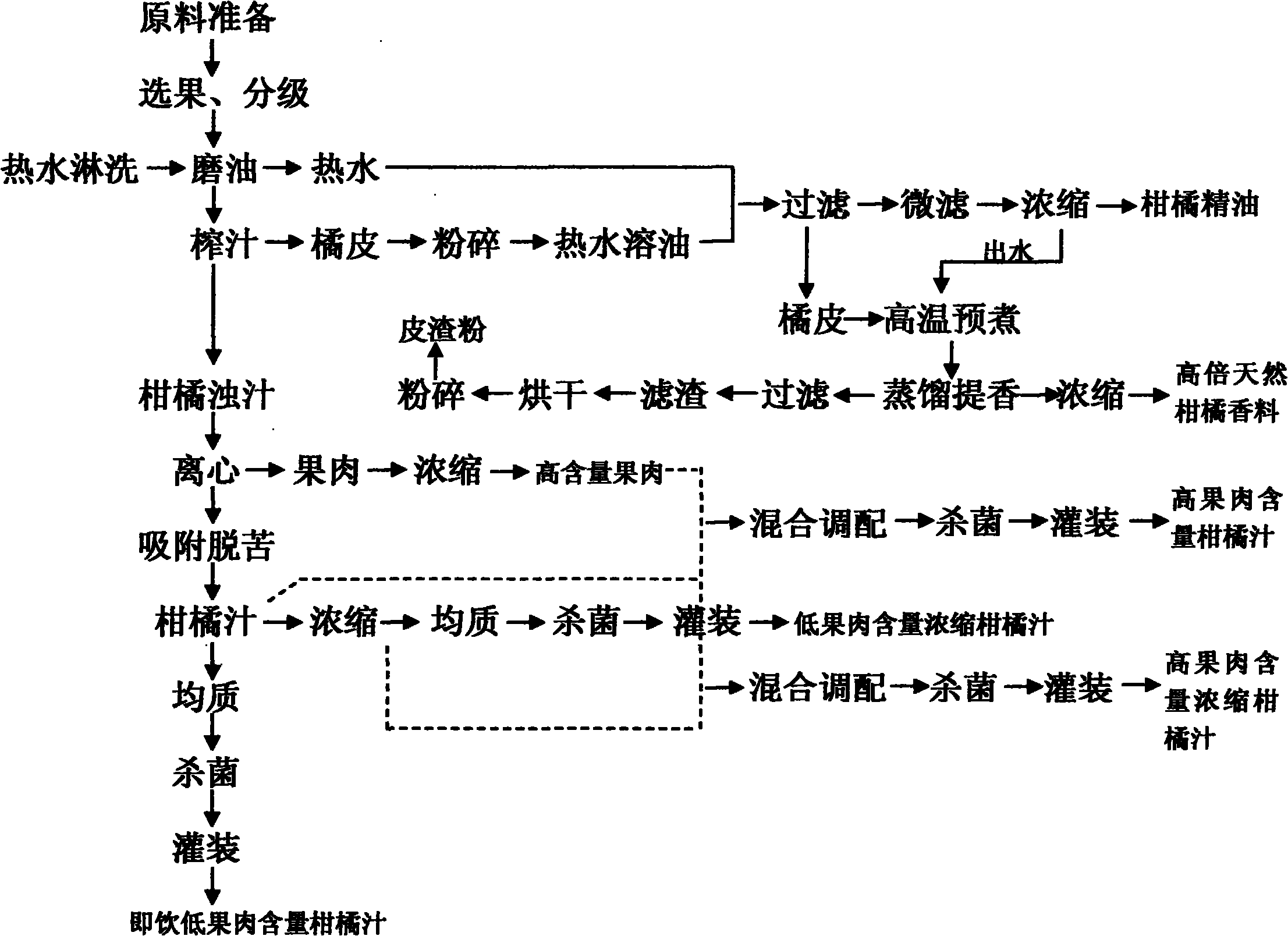

Method used

Image

Examples

Embodiment Construction

[0019] An environment-friendly processing and production method for seedless citrus, comprising the following steps:

[0020] 1) Raw material preparation: select seedless citrus raw materials, and high-pressure spray cleaning to ensure the cleanliness of the fruit for processing;

[0021] 2) Fruit selection and grading: pick out rotten and unqualified fruits, and grade the fruits for processing;

[0022] 3) Oil grinding: puncture the peel with an oil grinder to let the orange peel essential oil flow out, rinse the surface of the orange peel with 80°C hot water to accelerate the dissolution of the essential oil.

[0023] 4) Juicing: Use a flap-cut whole fruit juicer and a scraper homogenizer to squeeze the citrus juice to separate the citrus juice from the orange peel:

[0024] 5), centrifugation: use a centrifuge to centrifuge the turbid juice obtained in the juicing step 4) until the pulp content is less than 2%;

[0025] 6. Adsorption and debittering: part of the citrus ju...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com