Production method for honey pomelo preserved fruit

A production method and technology of honey pomelo, which are applied in confectionery, confectionery industry, food science and other directions, can solve the problems of insufficient degree of bitterness removal of honey pomelo peel, high boiling temperature, short boiling time for debittering, etc. The effect of mechanized packaging, good chewing taste and bright appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

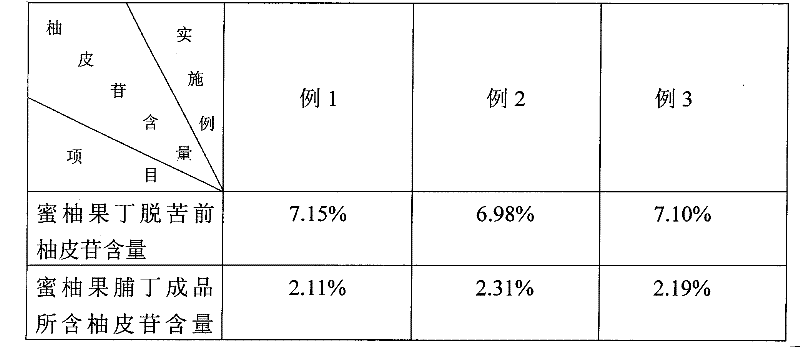

Embodiment 1

[0035] (1) Pretreatment of pomelo fresh fruit: the pomelo fresh fruit is automatically cleaned in hot water at 40-45°C for 2-3 minutes, then cooled and rinsed in clean water, disinfected at room temperature in a chlorine dioxide solution with a concentration of 100ppm and dried. , dividing the honey pomelo into sections, and separating the honey pomelo peel from the honey pomelo pulp;

[0036] (2), the pomelo peel enters the machine for dicing, and is sent to the diced pomelo grading device for grading to obtain qualified diced pomelo;

[0037] (3) The bittering element in the diced pomelo fruit is removed by the debittering liquid under vacuum condition, and the diced pomelo fruit after debittering is separated from the debittering liquid. Wherein the technological condition of vacuum debittering of diced honey pomelo fruit is:

[0038] The proportioning ratio of the debitter solution by weight percentage is:

[0039] Sodium Chloride 3% Sodium Tripolyphosphate 0.1%

[0040...

Embodiment 2

[0055] Its processing step (1), (2) and (7), (8) are identical with embodiment 1, and the processing condition of other steps is:

[0056] (3) The bittering element in the diced pomelo fruit is removed by the debittering liquid under vacuum condition, and the diced pomelo fruit after debittering is separated from the debittering liquid. Wherein the technological condition of vacuum debittering of diced honey pomelo fruit is:

[0057] The proportioning ratio of the debitter solution by weight percentage is:

[0058] Sodium Chloride 6% Sodium Tripolyphosphate 0.3%

[0059] β-cyclodextrin 1.2% balance water;

[0060] Vacuum degree 0.08Mpa,

[0061] Put the debittering liquid and diced pomelo fruit of the above formula into a vacuum debittering tank, the weight ratio of diced honeyd pomelo fruit to the debittering liquid is 1:5, and debitterize for 40 minutes at a temperature of 55°C and the above-mentioned vacuum degree;

[0062] (4) Vacuum sugaring to obtain candied pomelo d...

Embodiment 3

[0074] Its processing step (1), (2) and (7), (8) are identical with embodiment 1, and the processing condition of other steps is:

[0075] (3) The bittering element in the diced pomelo fruit is removed by the debittering liquid under vacuum condition, and the diced pomelo fruit after debittering is separated from the debittering liquid. Wherein the technological condition of vacuum debittering of diced honey pomelo fruit is:

[0076] The proportioning ratio of the debitter solution by weight percentage is:

[0077] Sodium Chloride 9% Sodium Tripolyphosphate 0.5%

[0078] β-cyclodextrin 2.0% balance water;

[0079] Wherein the solid content of fructose syrup is 70-72%;

[0080] Vacuum degree 0.12Mpa;

[0081] Put the debittering liquid and diced pomelo fruit of the above formula into a vacuum debittering tank, the weight ratio of diced honeyd pomelo fruit to the debittering liquid is 1:7, and debitterize for 20 minutes at a temperature of 75°C and the above-mentioned vacuum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com