Ultrasonic driving optical-fiber winding filter

A filter and piezoelectric driver technology, applied in the field of optical communication, can solve the problems such as the large space occupied by the optical fiber narrowband filter, the easy breakage and damage processing of the optical fiber filter, and the easy breakage of a single bare fiber, so as to increase the function expansion, Adjustable filter strength, simple processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

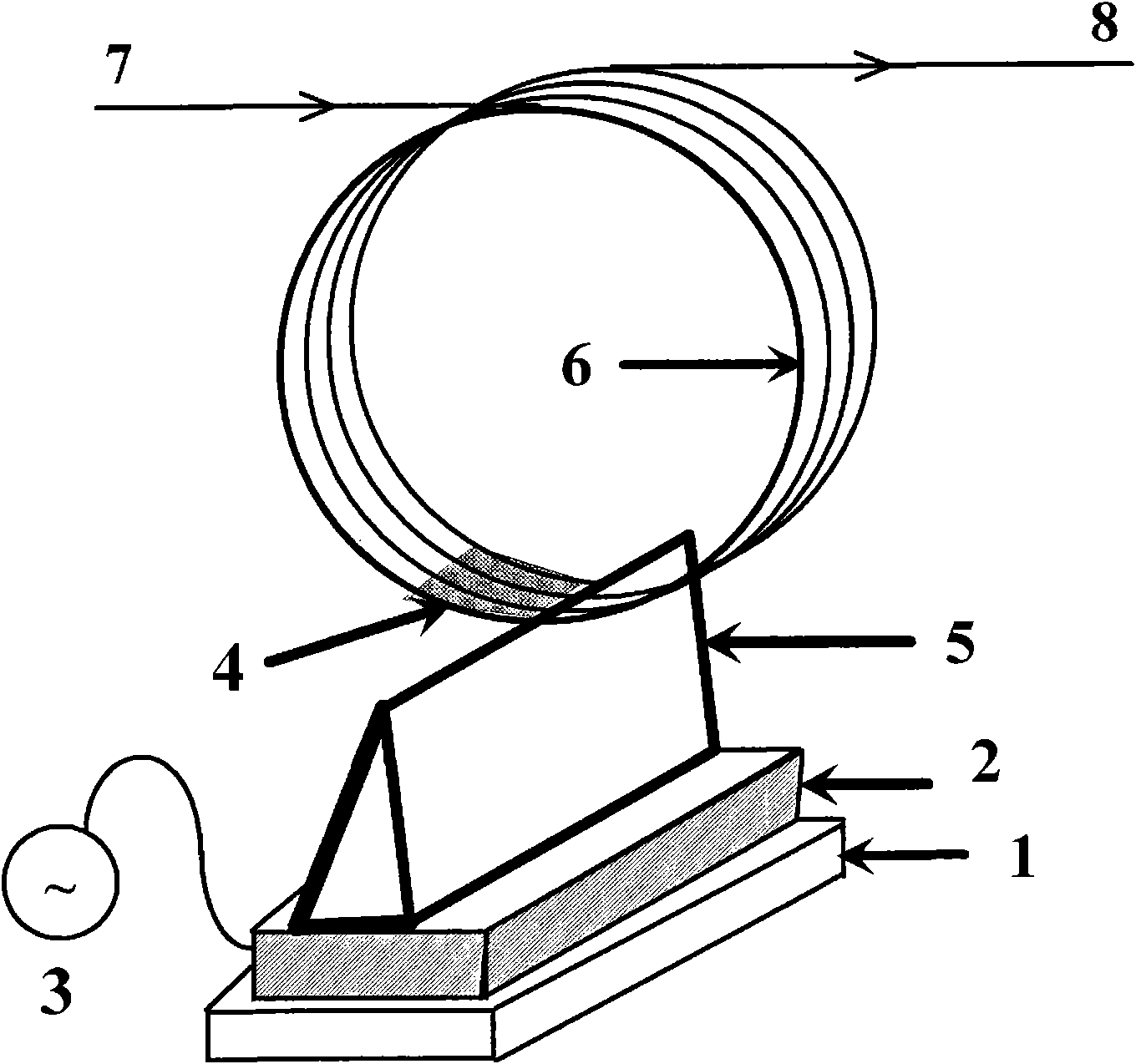

[0027] Ultrasound-driven optical fiber winding filter provided by the present invention comprises a wedge-shaped ultrasonic concentrator 5, and the bare fiber part 4 (in a single-layer close arrangement) of the optical fiber winding 6 that removes the coating layer is bonded at the wedge-shaped angle of the wedge-shaped ultrasonic concentrator At the edge of the cone, the piezoelectric driver 2 (ultrasonic transducer) used to drive the fiber winding is bonded to the bottom of the wedge-shaped ultrasonic concentrator, the piezoelectric driver is connected to the radio frequency signal source 3, and the bottom of the piezoelectric driver is bonded with a suction Acoustic material 1. The piezoelectric driver 2 is piezoelectric ceramics.

[0028] Some of the optical fibers in the optical fiber winding can be replaced with other optical fiber devices (such as fiber Bragg gratings) to form a novel filter.

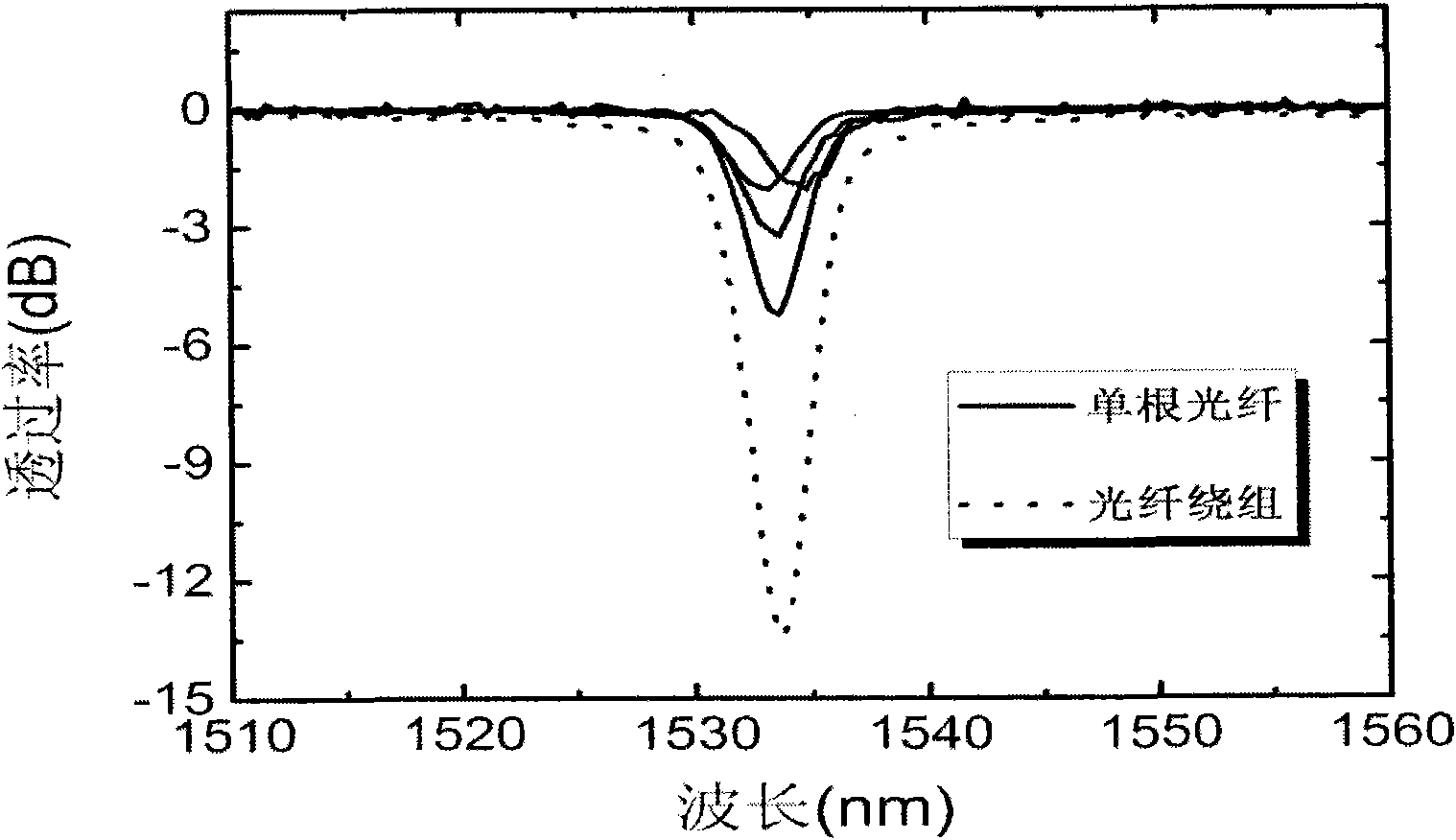

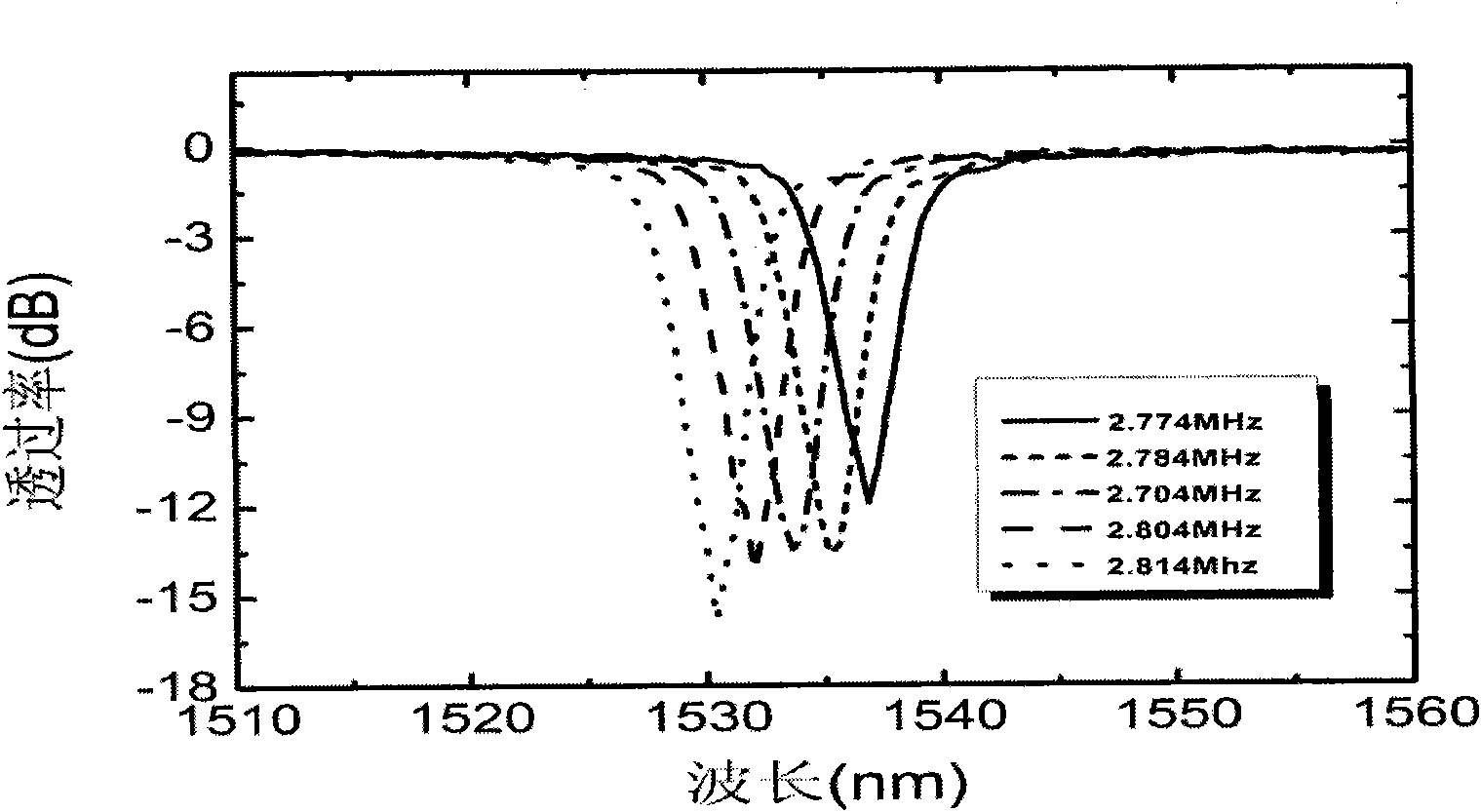

[0029] The prototype in this embodiment has been tested in principle accord...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Resonant frequency | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com