Detection method of grouting reinforcement effect in tunnel

A technology of grouting reinforcement and inspection method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc., which can solve problems such as time-consuming, inconvenient operation, and unusable measuring instruments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

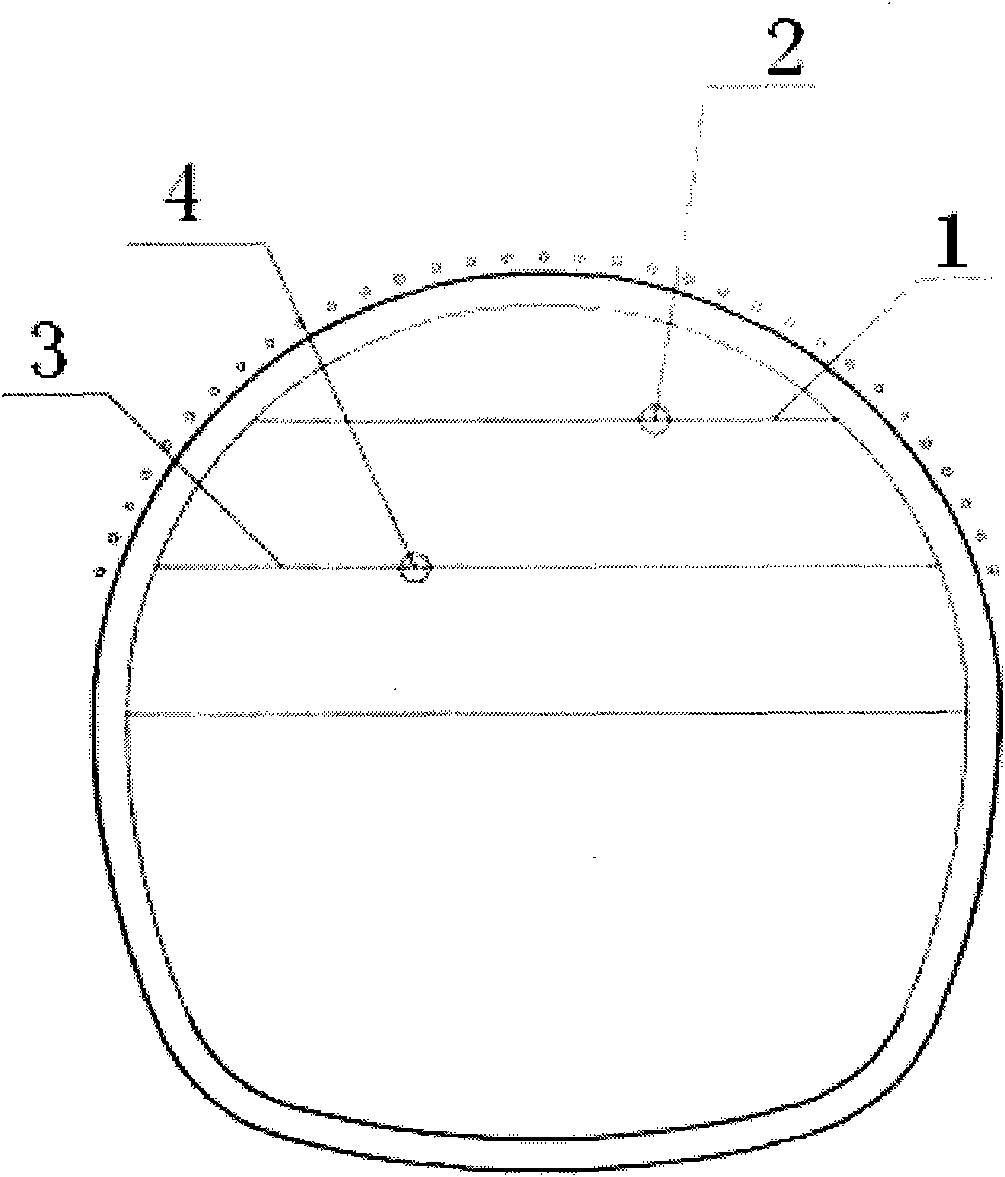

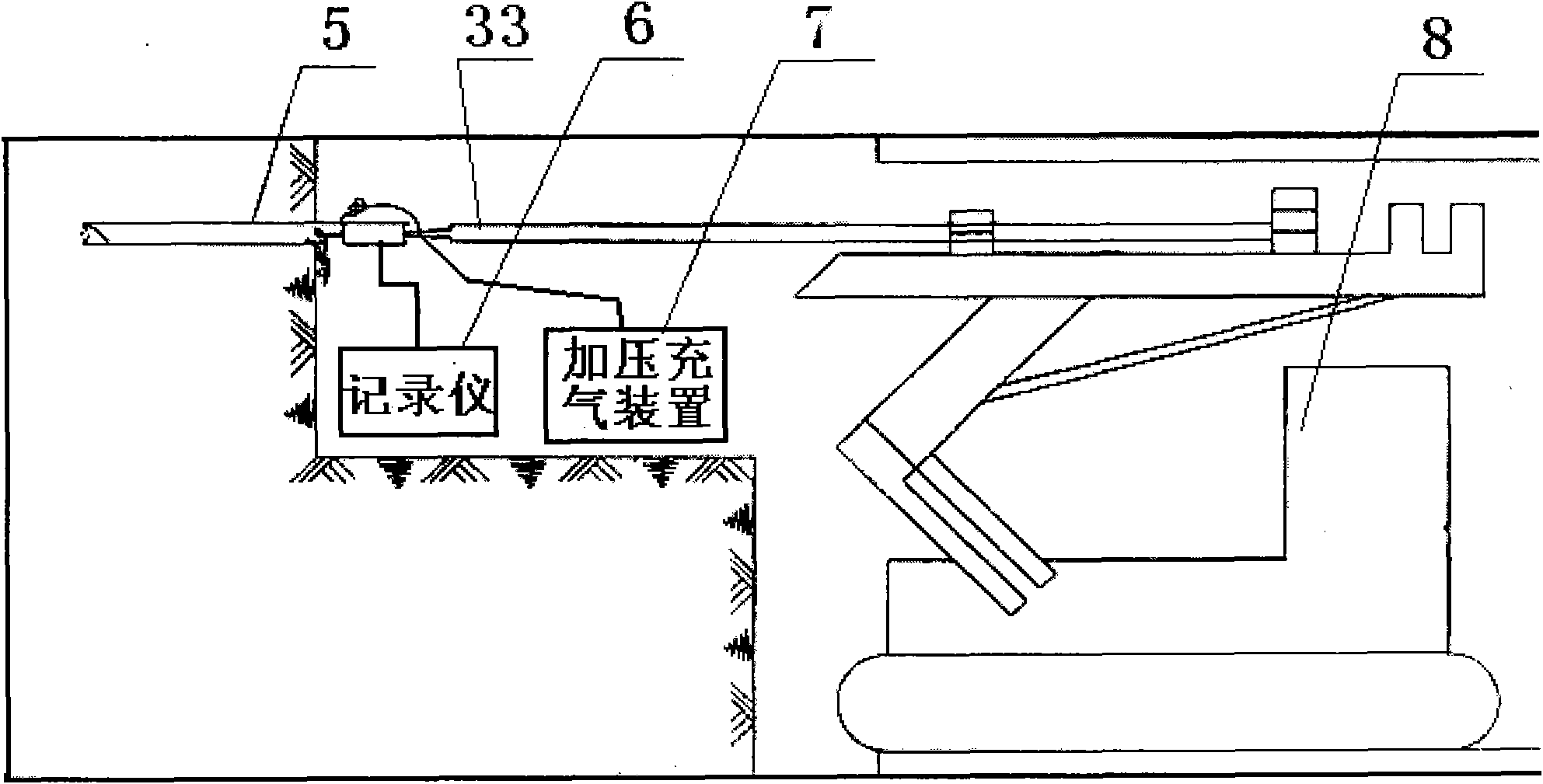

[0042] The principle of the present invention and its application are further described below with examples. to be in figure 1 To test the effect of grouting reinforcement on the face of the tunnel shown, it is necessary to: figure 2 The shown devices are the grouting reinforcement effect detection device 5 in the tunnel, the recorder 6 , the pressurization and inflation device 7 and the drilling rig 8 . The recorder 6 uses the SI series Tokyo digital display sensor head, the pressurization device 7 uses a high-pressure gas cylinder, and the drilling rig 8 is an RPD 150C advanced geological drilling rig.

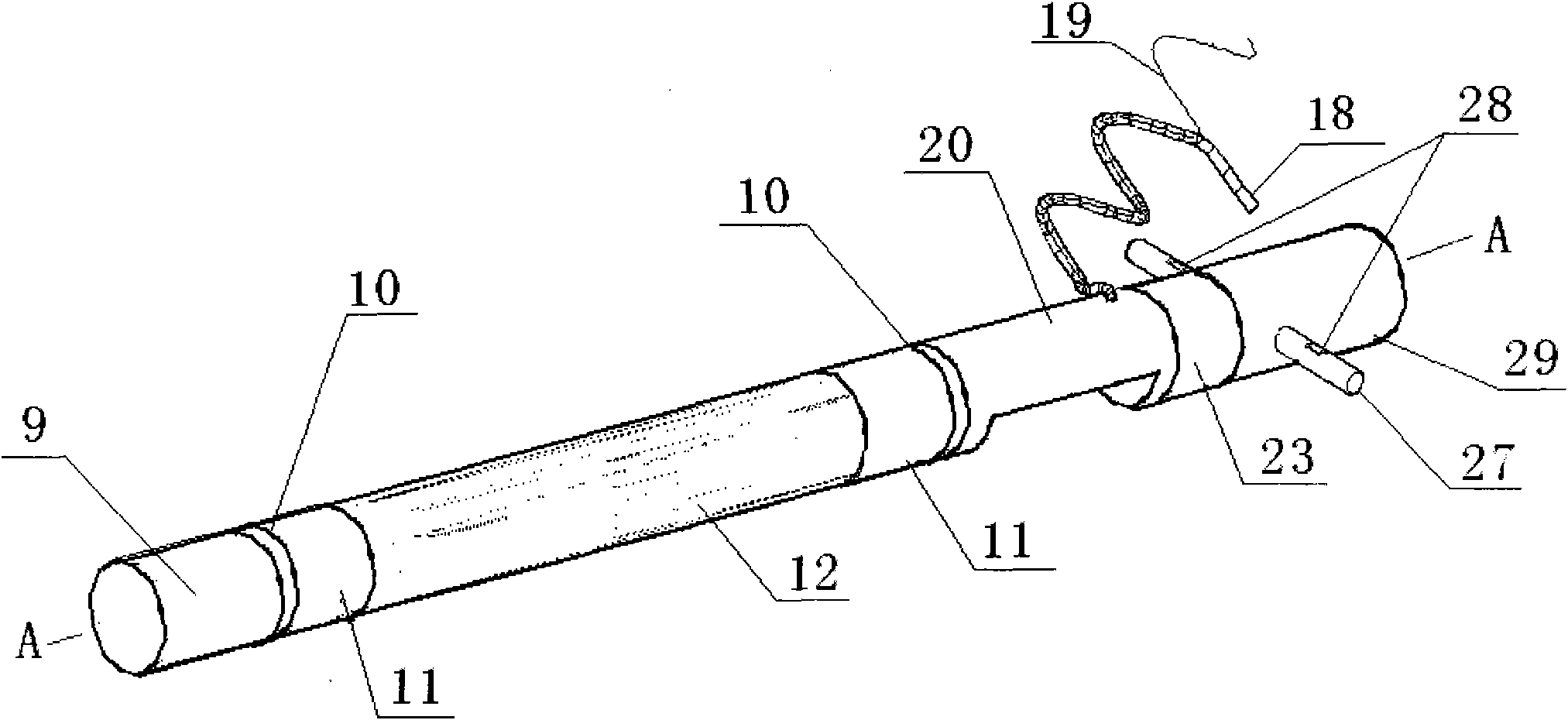

[0043] image 3 It is a schematic diagram of the three-dimensional structure of the grouting reinforcement effect detection device in the tunnel, Figure 4 yes image 3 The A-A sectional view of , that is, the schematic diagram of the internal structure of the detection device. The detection device is a cylindrical structure. From the front end to the tail end, it is c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com