Turbine parallel multiple-suction single-discharge vertical-type lifting pump

A technology of multi-suction and lifting pumps, which is applied in the direction of non-variable pumps, pumps, drive pumps, etc., can solve the problems of high cost and waste of resources, and achieve the effects of small footprint, extended service life, and compact equipment structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

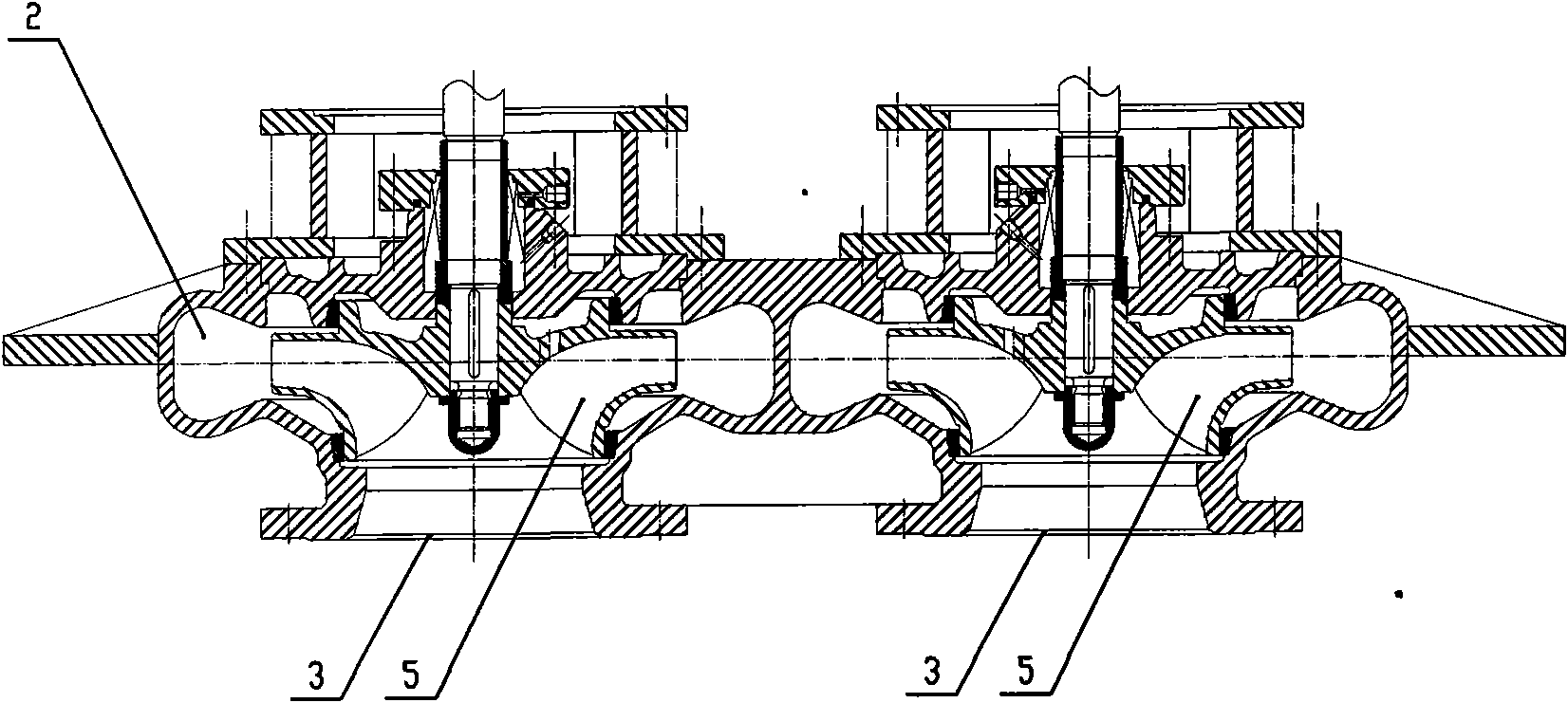

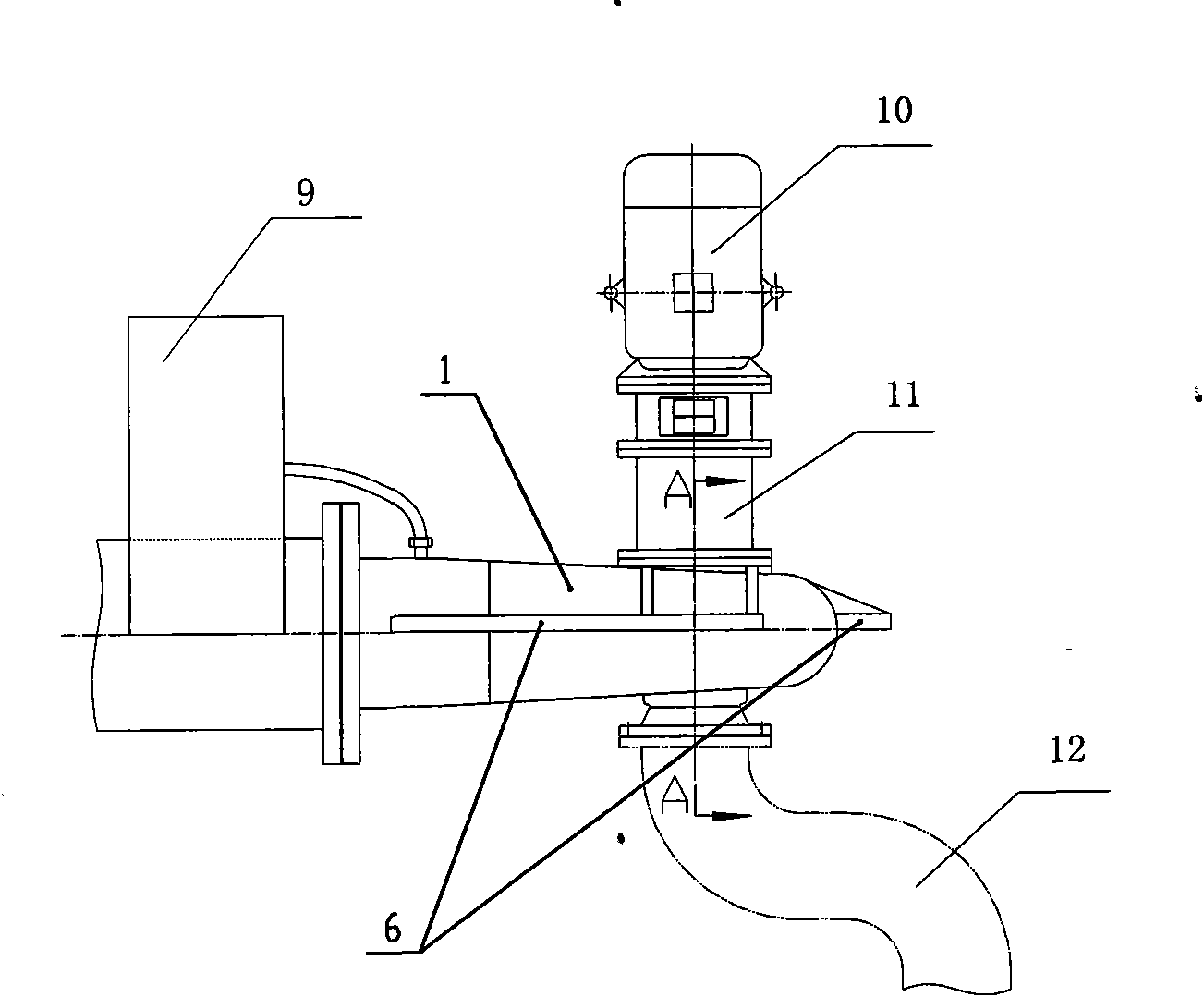

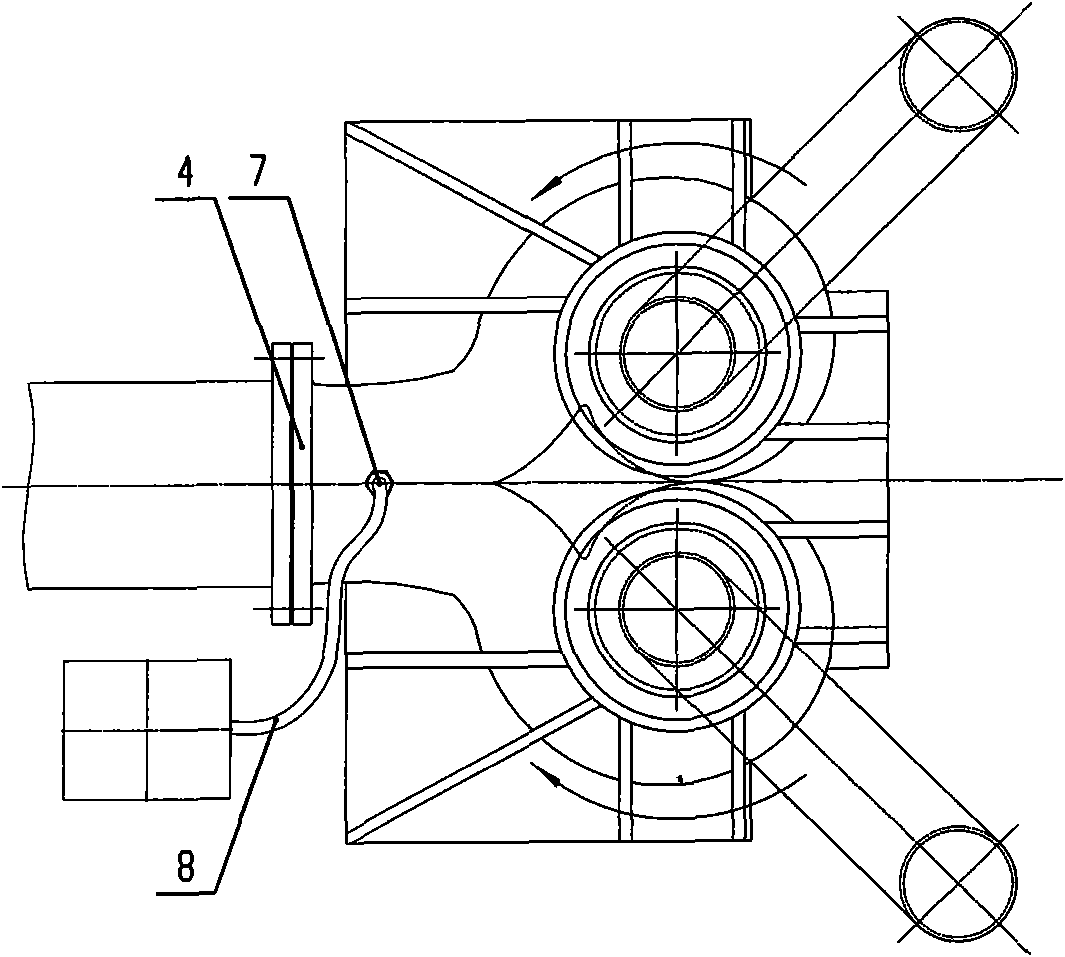

[0033] Such as Figure 1-3 As shown, the pump body 1 and the external suction pipe 12 are included, and two volute chambers 2 are arranged in parallel in the pump body 1, and the bottom of each volute chamber is respectively provided with a suction port 3, and the suction port 3 communicates with the external suction pipe 12; each Water pump impellers 5 are respectively installed in the volute, and the water pump impellers 5 are connected with the motor 10 through the pump shaft 11, and the motor 10 is arranged above the pump body 1; an output pipe 4 is provided on the pump body 1, and the output pipe 4 is connected to each worm The chambers 2 are all connected; the output pipe 4 is provided with a vacuum interface 7, which is airtightly connected with one end of the suction pipe 8, and the other end of the suction pipe 8 is connected with the vacuum turbine 9; outside the pump body 1, the volute chamber 2 radially install the support plate 6 at the center line.

Embodiment 2

[0035] Such as Figure 4 As shown, the volute chamber is arranged as four cores connected in parallel, the output pipe 4 is arranged as two, and other structures are the same as those in Embodiment 1.

Embodiment 3

[0037] Such as Figure 5 As shown, the volute chamber is arranged as three-core single-row combination, and other structures are the same as in Embodiment 1.

[0038] Start-up and running process of the present invention are as follows:

[0039] 1. Start the vacuum turbine, the vacuum turbine sucks out the air in the volute of the pump body through the suction pipe of the vacuum turbine airtightly connected with the outlet of the pump body, and the low-level water enters the volute chamber of the pump under the action of atmospheric pressure .

[0040] 2. Start the motor, the motor drives the vacuum turbine to close, the motor drives the impellers of each water pump to rotate simultaneously, and sends the water pressure sucked by each volute to the outlet shared by each volute for output.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com