Integral sandwiched porous fabric

A technology of porous fabrics and cores, applied in fabrics, textiles, textiles and papermaking, etc., can solve the problems of difficult continuous composite molding, limited mechanical properties, high manufacturing costs, etc., achieve broad market application prospects, avoid delamination problems, The effect of improving the overall strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

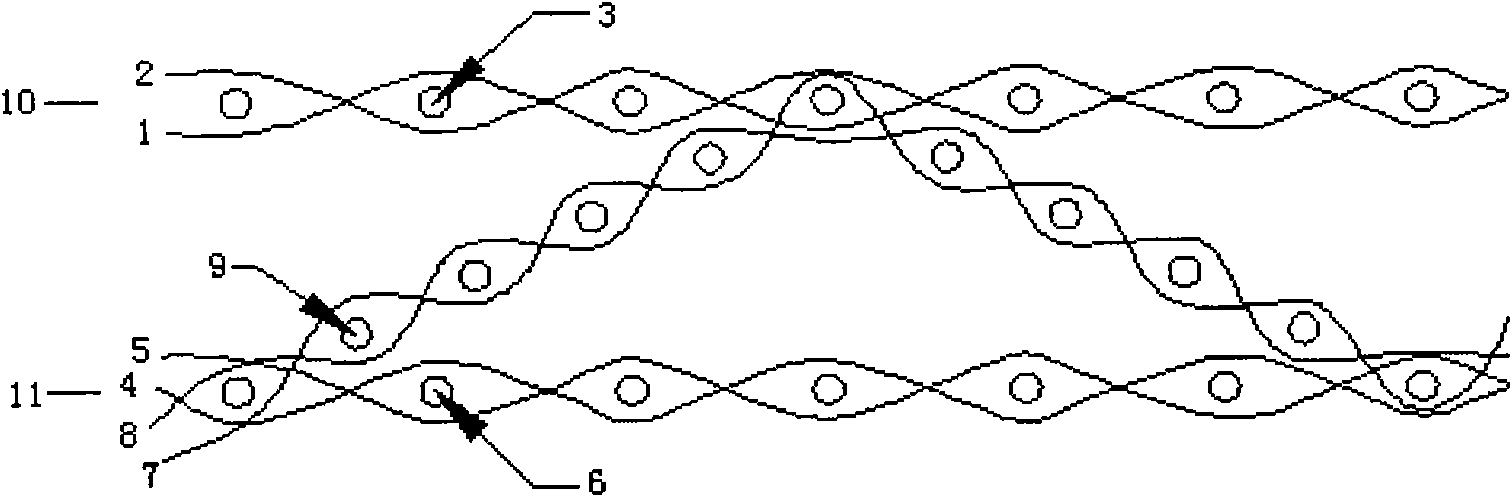

[0016] See attached figure 1 , this embodiment includes an upper layer 10 formed by interweaving the first upper layer warp yarn 1, the second upper layer warp yarn 2 and the upper layer weft yarn 3, and the first lower layer warp yarn 4, the second lower layer warp yarn 5 and the lower layer weft yarn 6 The lower layer 11 formed by interweaving, the upper layer and the lower layer are both one layer. After the first suede warp 7 and the second suede warp 8 are first interwoven with the lower layer weft yarn 6, they interweave successively with a plurality of sandwich weft yarns 9 distributed in a wave shape to the upper right, and interweave with the sandwich weft yarn 9 positioned at the top of the wave Finally, interweave with the weft yarn 6 of the upper layer, then turn around and interweave with the weft yarn 9 of the sandwich layer in turn to the lower right, and then interweave with the weft yarn 6 of the lower layer after arriving at the wave valley, and cycle accordi...

Embodiment 2

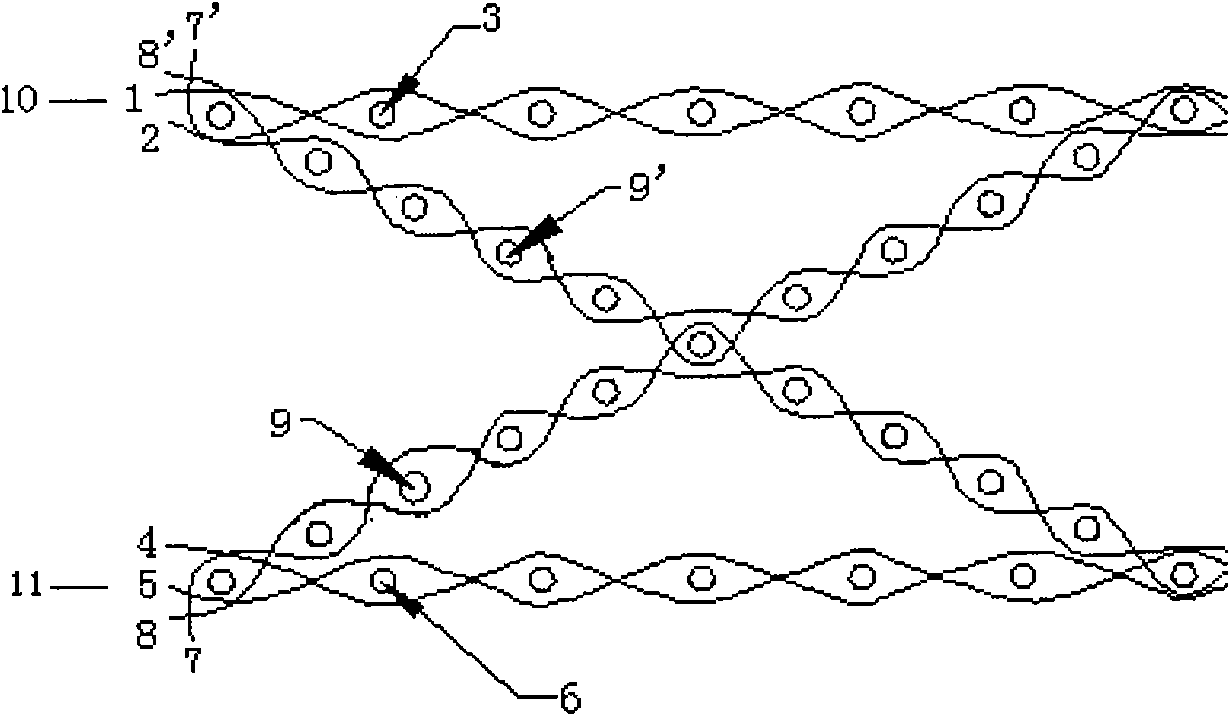

[0018] see figure 2 , the upper and lower layers of this embodiment are also the same as those of Embodiment 1. The difference is that the weft yarns of the sandwich layer are divided into two groups, namely the weft yarns of the sandwich layer 9 and the weft yarns of the sandwich layer 9', which are distributed in an "X" shape. Correspondingly, the first suede warp and the second suede warp are also divided into two groups. The first pile warp 7 and the second pile warp 8 of the first group first interweave with the lower layer weft yarn 6, then interweave with the first group of sandwich layer weft yarn 9 to the upper right, and finally interweave with the upper layer weft yarn 3. Second group of the first suede warp 7' and the second suede warp 8' first interweave with the upper layer weft yarn 3, then interweave with the second group of sandwich layer weft yarn 9' successively to the lower right, and finally interweave with the lower layer weft yarn 6. Finally, a two-di...

Embodiment 3

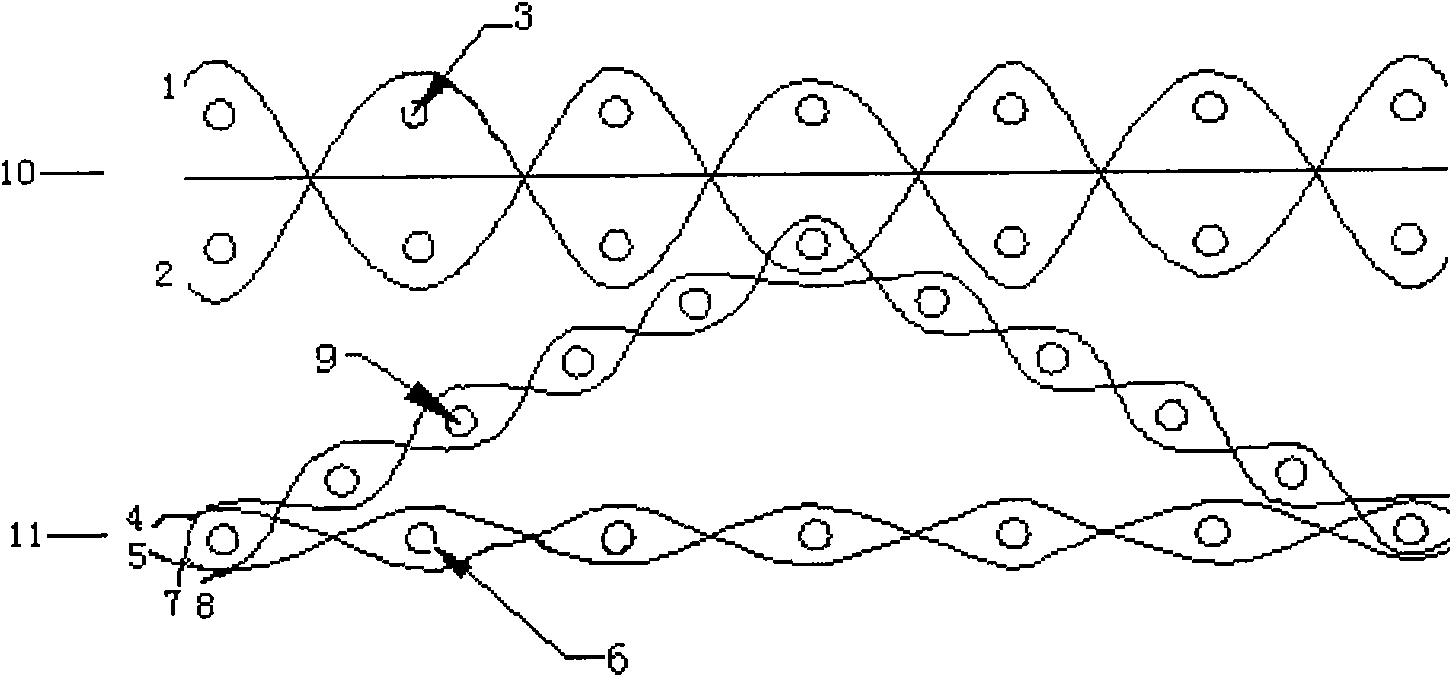

[0020] The lower layer and sandwich layer of this embodiment are the same as those of Embodiment 1, the difference is that there are two groups of weft yarns 3 on the upper layer, and the two groups of weft yarns 3 are arranged in parallel from top to bottom. The warp yarn 1 of the first upper layer and the warp yarn 2 of the second upper layer are interwoven with two sets of weft yarns 3 of the upper layer at the same time, thereby forming a thickened upper layer composed of two layers. The thicker the thickness.

[0021] In addition to the solution shown in this embodiment, the thickness of the lower layer can also be increased by increasing the number of groups of weft yarns in the lower layer.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com