Method for producing a seamless steel pipe and rolling mill for performing the method

A technology of seamless steel pipes and rolling mills, applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of low output of rolled pieces, uneven capillary temperature, long rhythm time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

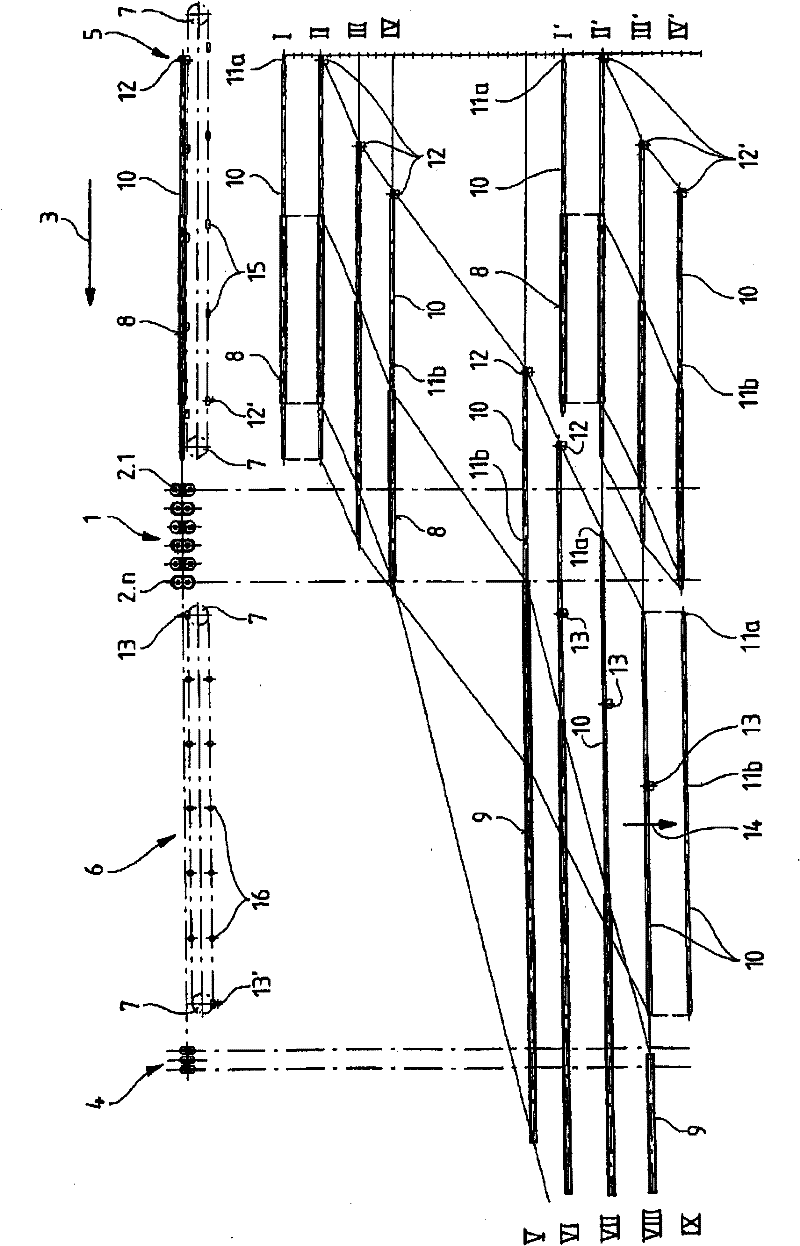

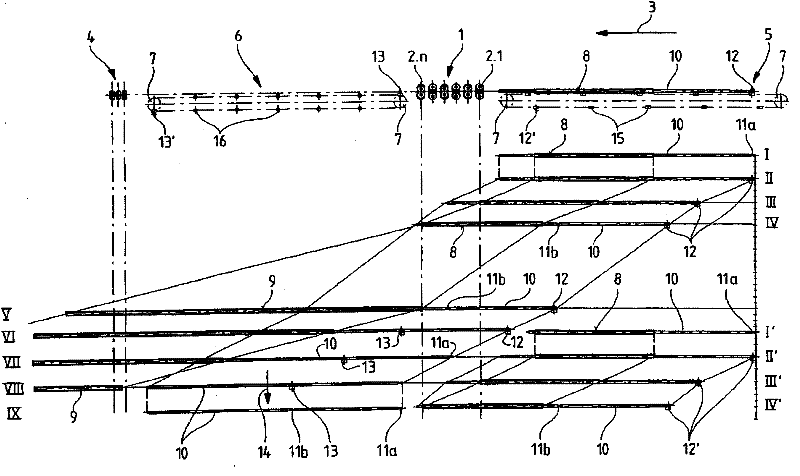

[0016] According to this very illustrative appendix picture As shown, the rolling plant for producing seamless steel pipes in a continuous rolling process comprises: a continuous rolling mill 1, which here consists of six successive stands 2.1 to 2.n; The stripping machine 4 after the continuous rolling mill; and the first mandrel holding and conveying device 5 arranged before the first stand 2.1 on the entry side; the last stand 2.n of the continuous rolling mill 1 arranged in-line and Another second mandrel holding and conveying device 6 between the pipe extractors 4 . The first and second mandrel holding and conveying devices 5 , 6 are chain holders guided around a sprocket 7 .

[0017] In order to roll a hollow billet 8 previously produced in a piercing mill (not shown) into a hollow shell 9, a mandrel 10 is inserted into the hollow billet 8, as in the mandrel movement modes processes I to IX I, and in this hollow blank-mandrel combination 8, 10, said mandrel is loaded o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com