Bone-strengthening food material

一种级分、乳蛋白质的技术,应用在不明原材料、食品制备、食品成分等方向,能够解决不能食品原材料使用等问题,达到抑制骨量减少、促进钙化的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

reference example 1

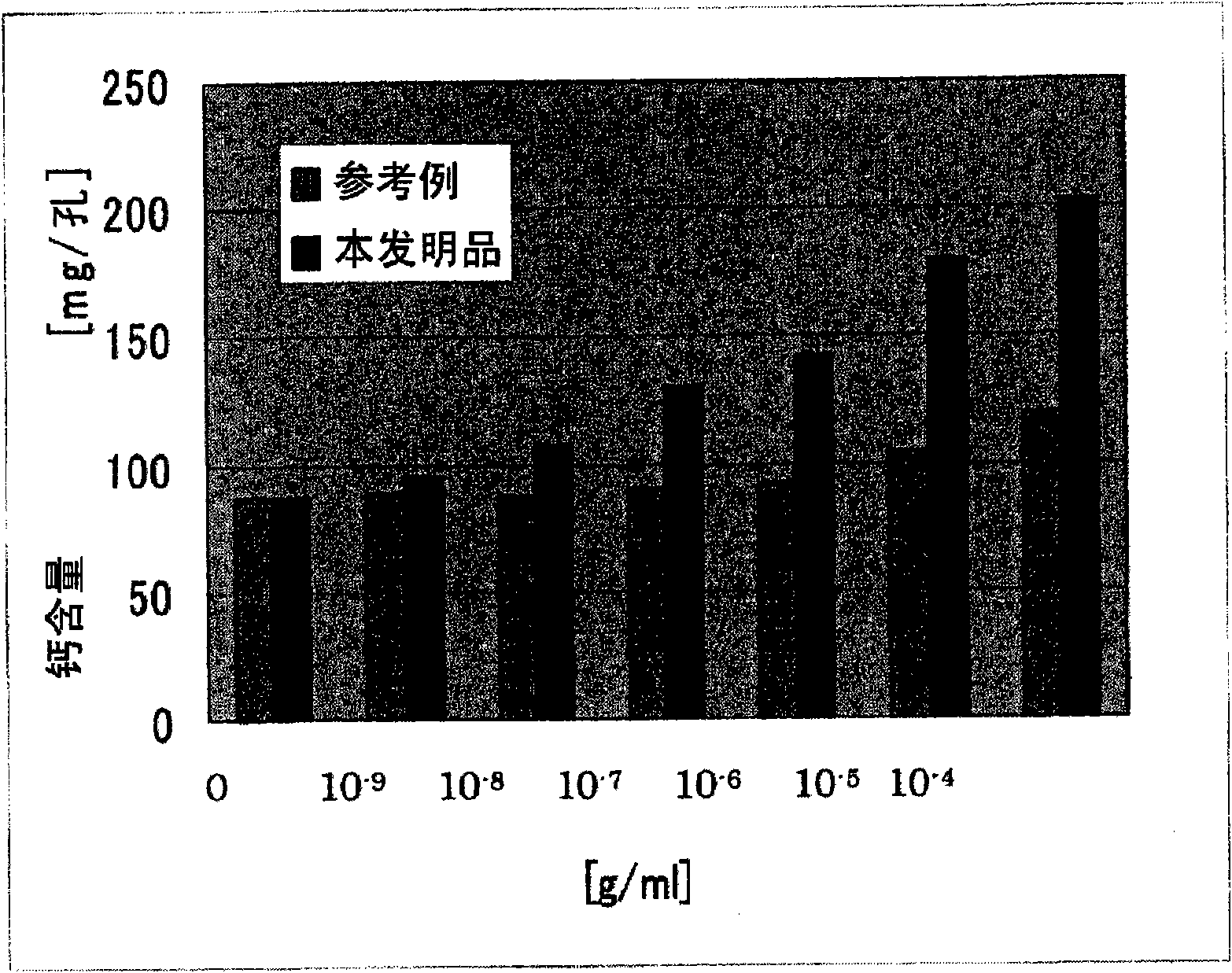

[0041] According to the following method (see Japanese Patent No. 3112637), a commercially available milk protein fraction whose bone strengthening effect was confirmed was prepared.

[0042] A column with a diameter of 10 cm filled with 0.5 liter of sulfonated Chitopearl (manufactured by Fuji Industries) as a cation exchange resin was sufficiently washed with deionized water. After making 50 liters of non-sterilized skim milk pass through the column with a flow rate of 100ml / min, the column is fully washed with deionized water, and 2.5 liters of 0.05M phosphate buffer solution (pH7.0) containing 0.95M sodium chloride is passed through the column so that Proteins adsorbed to the resin are eluted. Then, the eluate was desalted and concentrated by reverse osmosis (RO) membrane treatment, and then freeze-dried to obtain a powdery milk protein fraction. This operation was repeated twice to obtain 104 g of protein fractions. The isoelectric point of this protein fraction is 7.0-8...

Embodiment 1

[0044] A column with a diameter of 10 cm filled with 0.5 liter of sulfonated Chitopearl (manufactured by Fuji Industries) as a cation exchange resin was sufficiently washed with deionized water. After making 50 liters of non-sterilized skim milk pass through the column with a flow rate of 100ml / min, the column is fully washed with deionized water, and 2.5 liters of 0.05M phosphate buffer solution (pH7.0) containing 0.15M sodium chloride is passed through the column so that Proteins adsorbed to the resin are eluted. Then, the eluate was desalted and concentrated by reverse osmosis (RO) membrane treatment, and then freeze-dried to obtain a powdery milk protein fraction. This operation was performed 10 times, and 24.2 g of milk protein fractions were obtained. The molecular weight of this fraction is 6,000 to 150,000 Daltons, the isoelectric point is 6.0 to 11.0, and the basic amino acid is 12 to 14% of the constituent amino acids contained in this milk protein fraction. Moreov...

Embodiment 2

[0046] A column with a diameter of 10 cm filled with 0.5 liter of sulfonated Chitopearl (manufactured by Fuji Industries) as a cation exchange resin was sufficiently washed with deionized water. After making 50 liters of non-sterilized skim milk pass through the column with a flow rate of 100ml / min, the column was fully washed with 0.05M phosphate buffer (pH7.0) containing 0.05M sodium chloride to make the 0.05M solution containing 0.25M sodium chloride 2.5 liters of phosphate buffer (pH 7.0) was passed through the column to elute the protein adsorbed on the resin. Then, the eluate was desalted and concentrated by reverse osmosis (RO) membrane treatment, and then freeze-dried to obtain a powdery milk protein fraction. This operation was performed 5 times, and 12.8 g of milk protein fractions were obtained. The molecular weight of this fraction is 6,000 to 150,000 Daltons, the isoelectric point is 6.0 to 11.0, and the basic amino acid is 12 to 14% of the constituent amino acid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com