Near-field ultrasound floated-type gyroscope

A gyroscope and ultrasonic technology, applied in the field of gyroscope, can solve the problems of no gyroscope, complex system structure, limited application of suspended gyroscope, etc., and achieve the effect of compact structure, avoiding interference torque, and high processing and assembly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

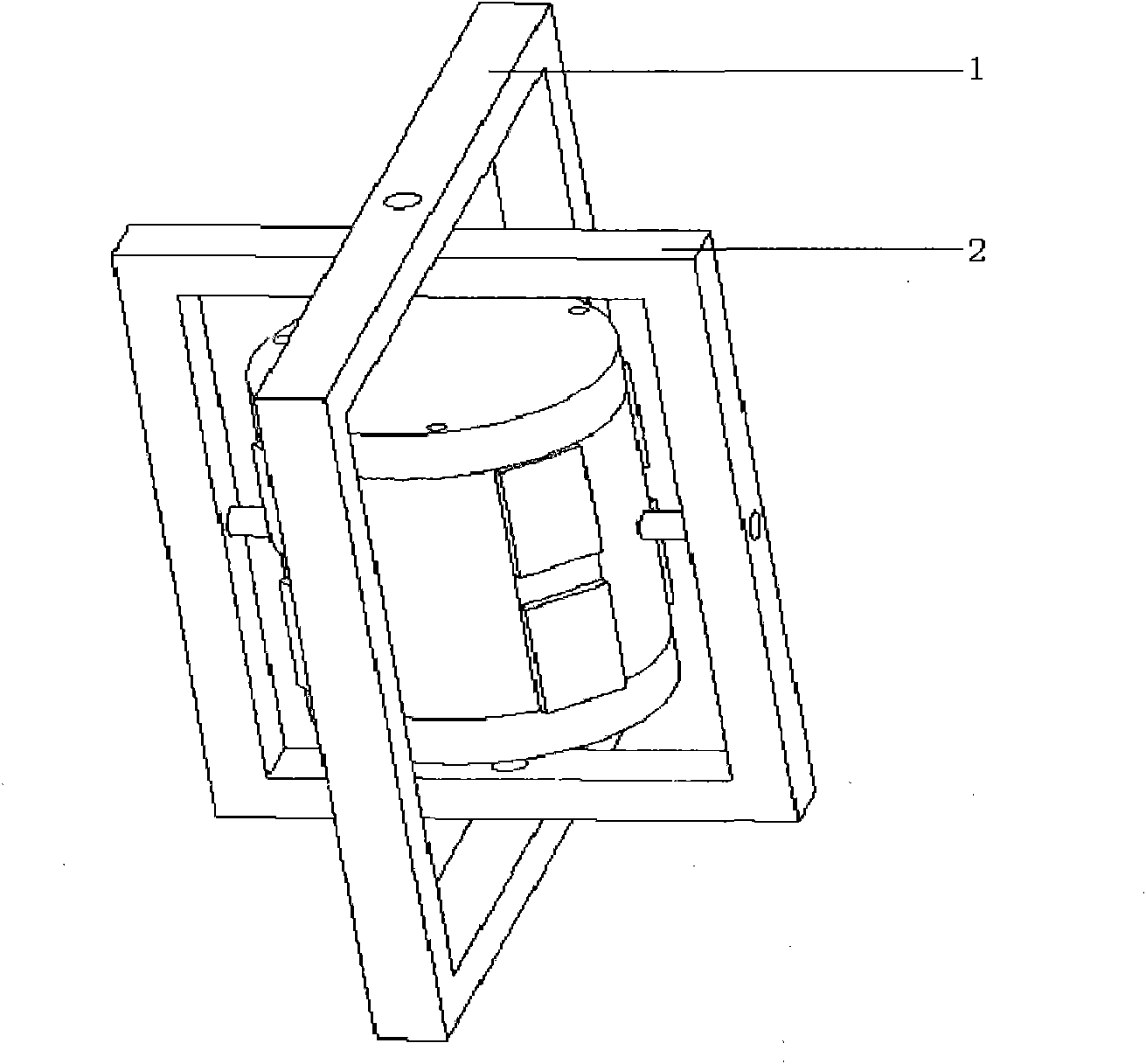

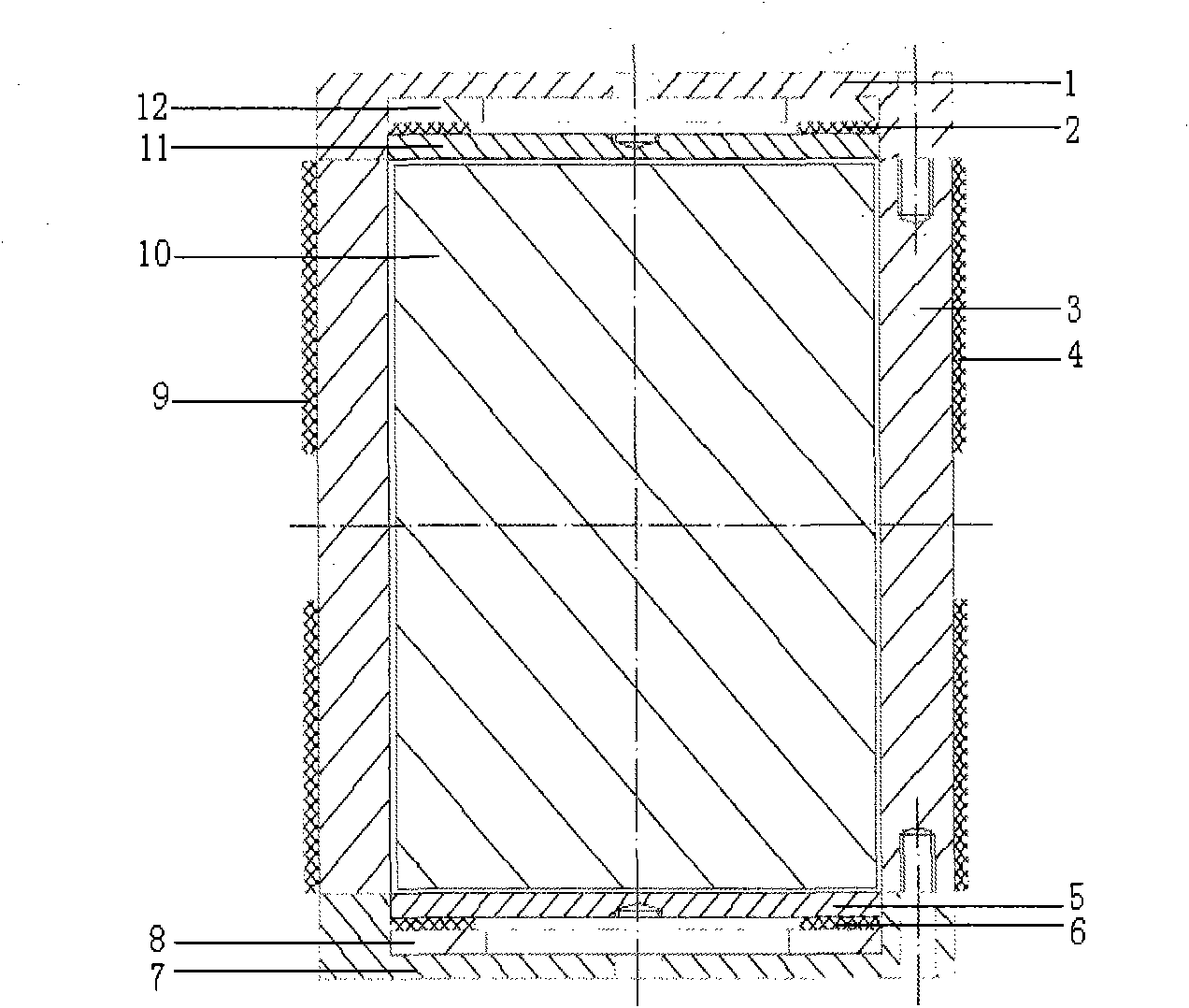

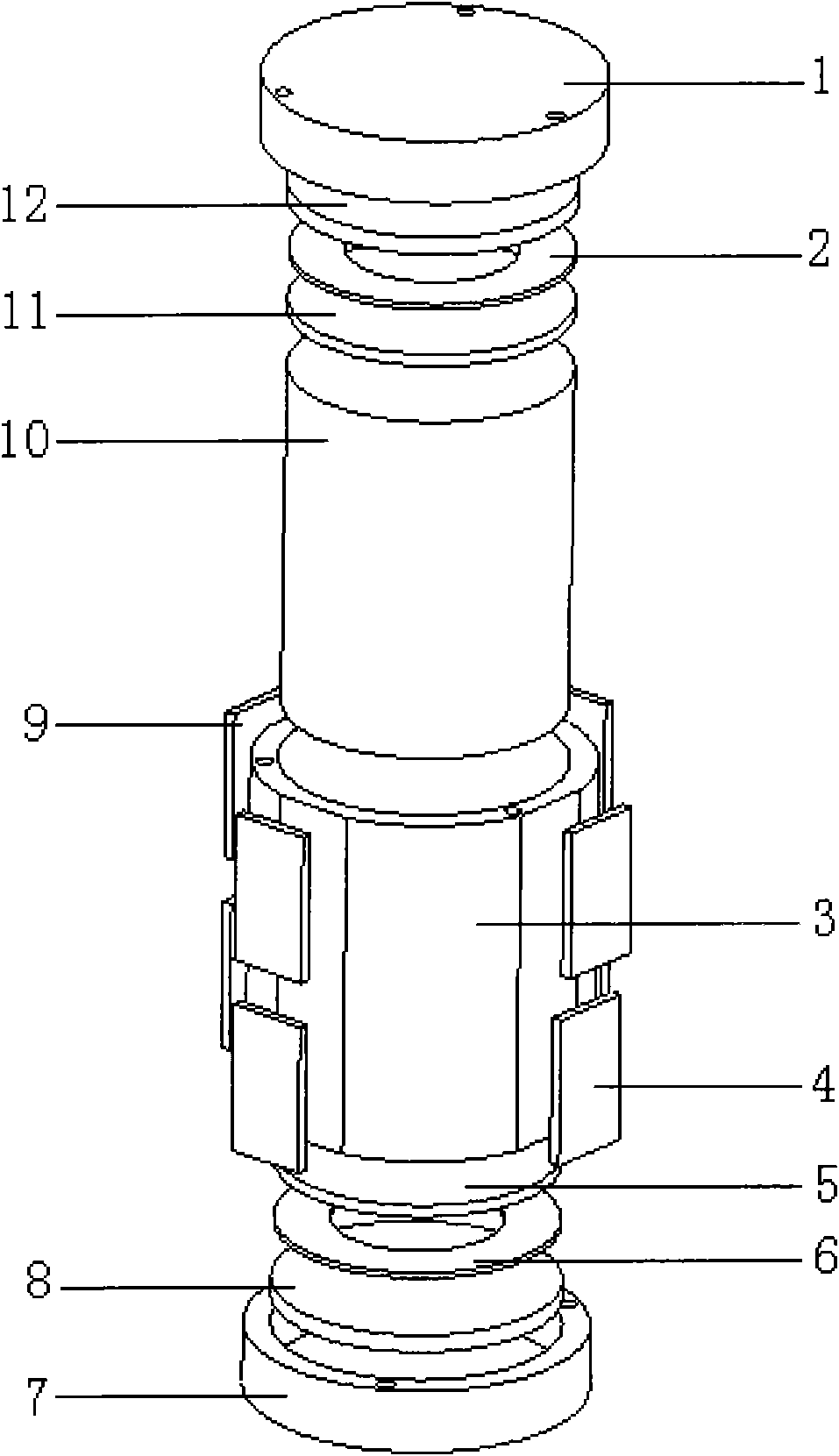

[0018] The near-field ultrasonic suspension gyroscope of the present invention is made based on the inverse piezoelectric effect of piezoelectric ceramics, and its structure refers to figure 2 and image 3 , including: cylindrical stator 3, rotor 10, upper and lower end covers 1 and 7, upper and lower elastic pads 8 and 12, upper and lower annular ceramic sheets 2 and 6, upper and lower axial suspension support plates 5 and 11, pasted on cylindrical stator 3 There are cylindrical stator ceramics 4, and there are 8 pieces of cylindrical stator ceramics 4 in total, of which 4 pieces form a group, symmetrically distributed at both ends of the radial direction of the cylindrical stator, and each end includes two upper and lower pieces, and two groups of 8 pieces are evenly distributed on the On the circumference of the cylindrical stator 3 , an annular ceramic sheet 2 is placed between the axial suspension support plate 5 and the elastic pad 8 , and an annular ceramic sheet 6 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com