Active balance pressure jet refrigeration system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

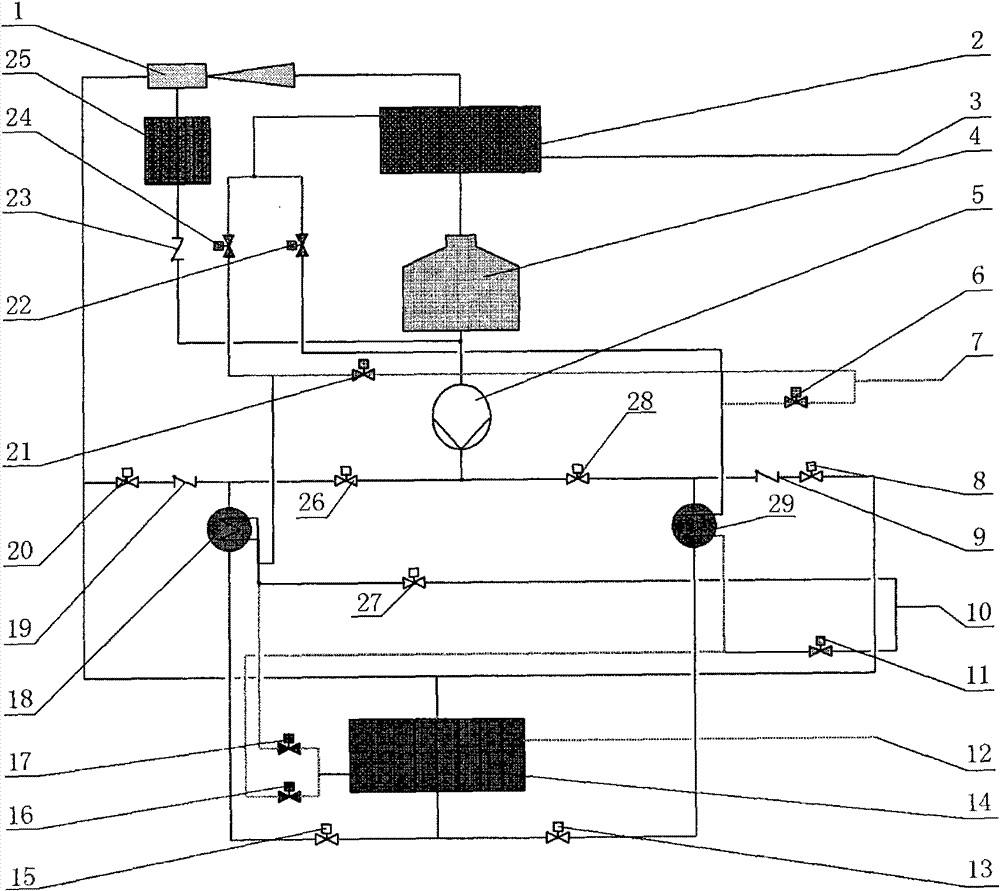

[0011] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

[0012] Two heat exchangers are added in the traditional jet refrigeration system, the first heat exchanger 18 and the second heat exchanger 29 use the hot water from the outlet of the generator 14 to preheat the refrigerant liquid, and the two heat exchangers operate alternately.

[0013] The driving heat source of the present invention comes from the hot water produced by the hot water preparation device by using the solar energy or the production waste heat of the factory. In the present invention, the working process is as follows: process 1, the first heat exchanger 18 is empty, the cooling water coming out from the condenser 2 is passed into the pipe, the liquid pump 5 is turned on, and the refrigerant liquid is transferred from the liquid accumulator 4 below the condenser 2 It is sent to the first heat exchang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com