Biological carbonaceous filler and preparation method thereof

A bio-carbon and biomass technology, applied in sustainable biological treatment, chemical instruments and methods, biological water/sewage treatment, etc., can solve the problems of increasing the load of organic matter in water, frequent addition and replacement of fillers, unstable properties of organic matter, etc. Less equipment, beneficial to carbon dioxide emission reduction, easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

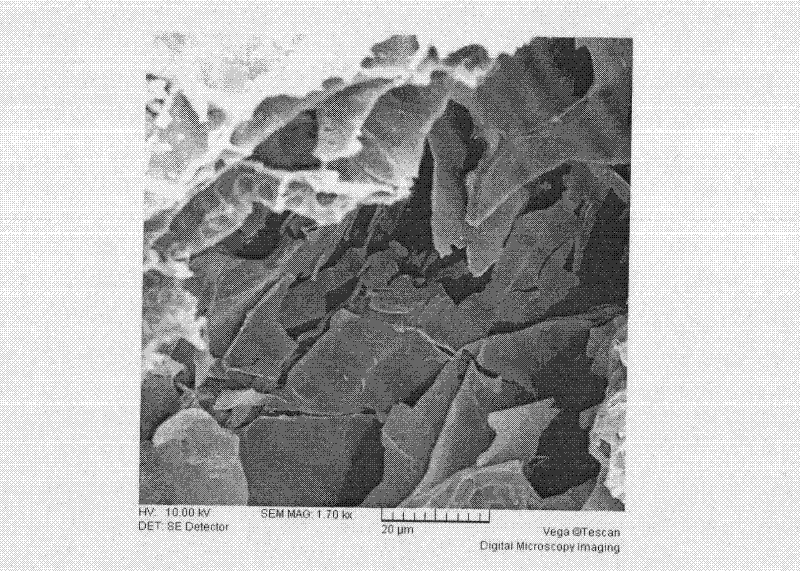

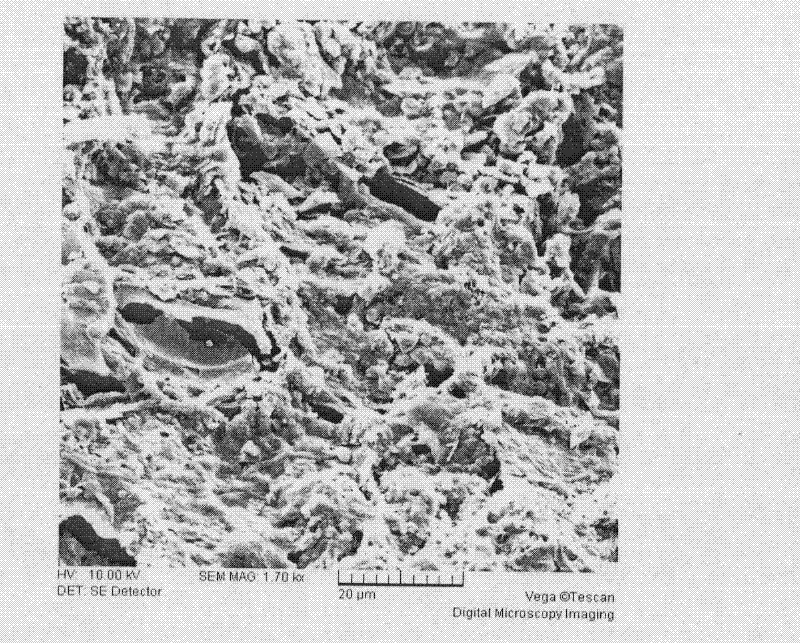

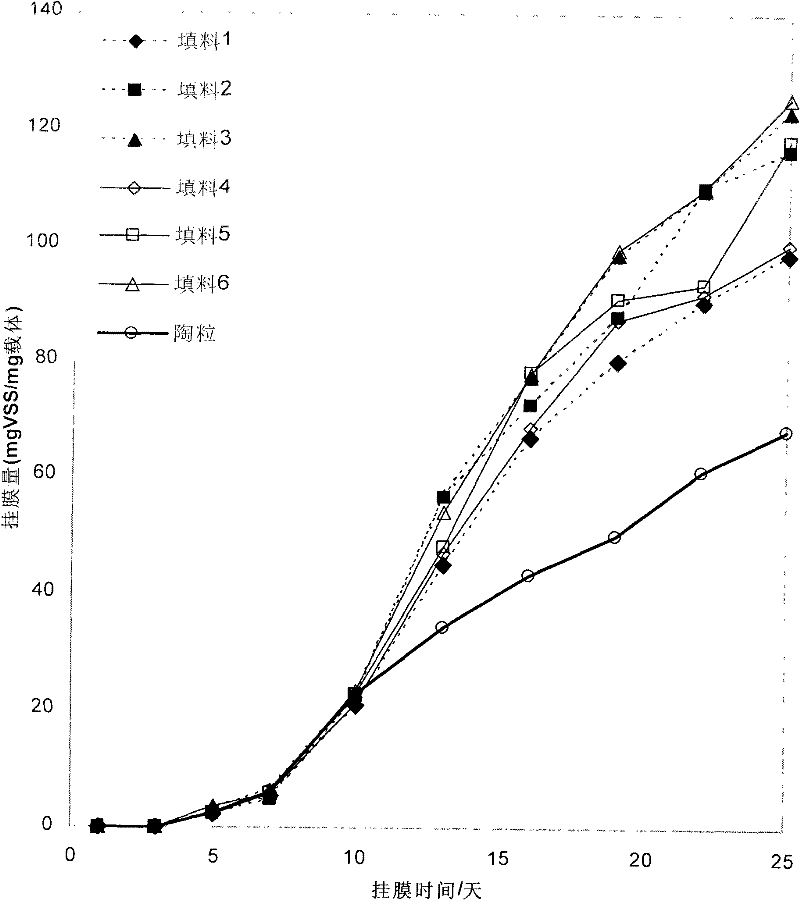

[0022] Wash the peanut shells, dry them naturally, put them into a crucible with a cover, and send them to a muffle furnace for slow pyrolysis after sealing. The final temperature of pyrolysis is 300°C, and the pyrolysis time is 1h. The pyrolyzed solid product was soaked in 0.1mol / L HCl solution for 12 hours, then rinsed repeatedly with distilled water for 3 times, and dried in an oven at 105°C for 12 hours. After being taken out, it is crushed into particles with a size of 0.5-1.5 cm, and then the biological carbonaceous filler 1 is made.

Embodiment 2

[0024] Wash the peanut shells, dry them naturally, put them into a crucible with a cover, and send them to a muffle furnace for slow pyrolysis after sealing. The final temperature of pyrolysis is 500°C, and the pyrolysis time is 1h. The pyrolyzed solid product was soaked in 0.1mol / L HCl solution for 12 hours, then rinsed repeatedly with distilled water for 3 times, and dried in an oven at 105°C for 12 hours. After being taken out, it is crushed into particles with a size of 0.5-1.5 cm, and then the biological carbonaceous filler 2 is made.

Embodiment 3

[0026] Wash the peanut shells, air dry them naturally, put them into a crucible with a cover, and send them to a muffle furnace for slow pyrolysis after sealing. The pyrolyzed solid product was soaked in 0.1mol / L HCl solution for 12 hours, then rinsed repeatedly with distilled water for 3 times, and dried in an oven at 105°C for 12 hours. After being taken out, it is crushed into particles with a size of 0.5-1.5 cm, and then the biological carbonaceous filler 3 is made.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com