Rubber combination and diaphragm containing same

A rubber diaphragm and rubber technology, applied in rubber layered products, layered products, chemical instruments and methods, etc., can solve the problems of hardening, loss of elasticity, oil resistance and high weight change rate of the diaphragm, and achieve low and low temperature resistance. Performance, ease of implementation, good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

[0027] The rubber compositions were formulated according to the formulations listed in Table 1. First, mix the nitrile rubber and the second rubber evenly on an open mill; then mix the mixed rubber and other prepared raw materials through an internal mixer; impregnate and dry the skeleton material cloth nylon with 589 resin; dry the dried skeleton material The mixed rubber is calendered on a calender as required; the rolled semi-finished product is vulcanized by a drum vulcanizer, the pressure of the vulcanizer is controlled at 18-20Mpa, and the temperature is maintained at 155-165°C.

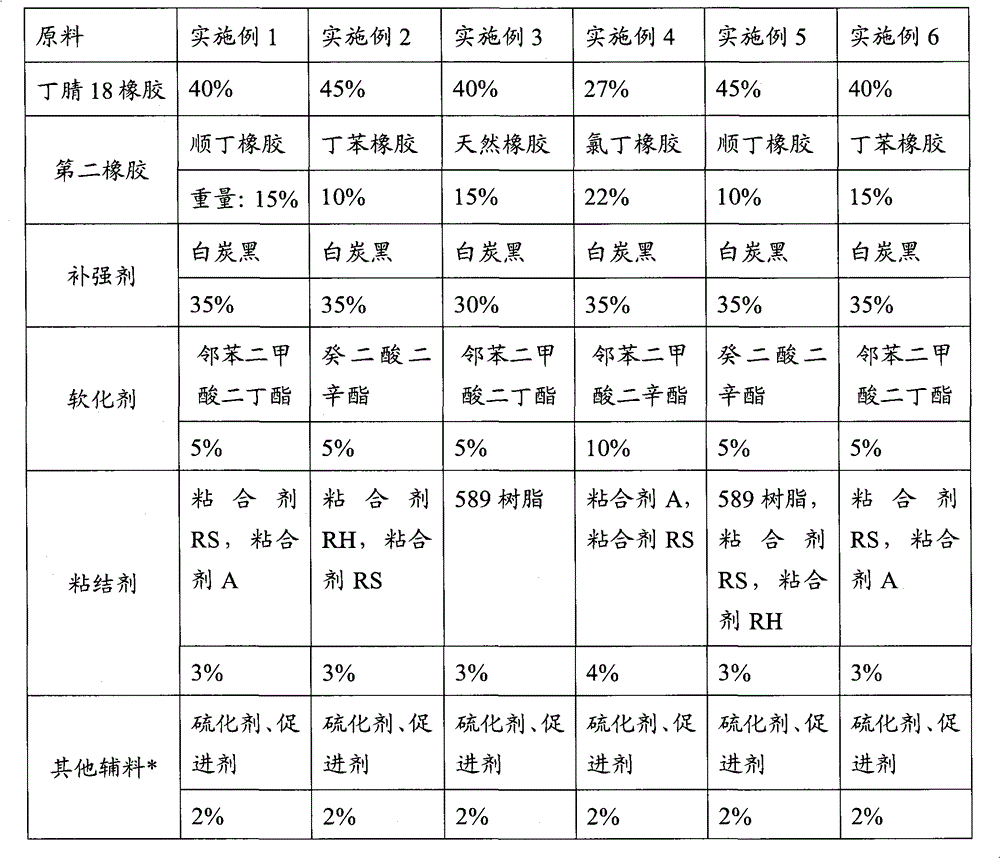

[0028] Table 1. Raw material proportioning of embodiment 1-7

[0029]

[0030] * The vulcanizing agent is a mixture of sulfur and dithiodimorpholine (DTDM); the accelerator is N, N'-tetramethyldithiodithiocarbamide (TMTD)

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| adhesivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com