Interproximal teeth cleaning apparatus with an air-driven spray

A gap and tooth technology, applied in the field of tooth cleaning equipment, can solve problems such as difficult to operate effectively, time-consuming flossing, bleeding gums, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

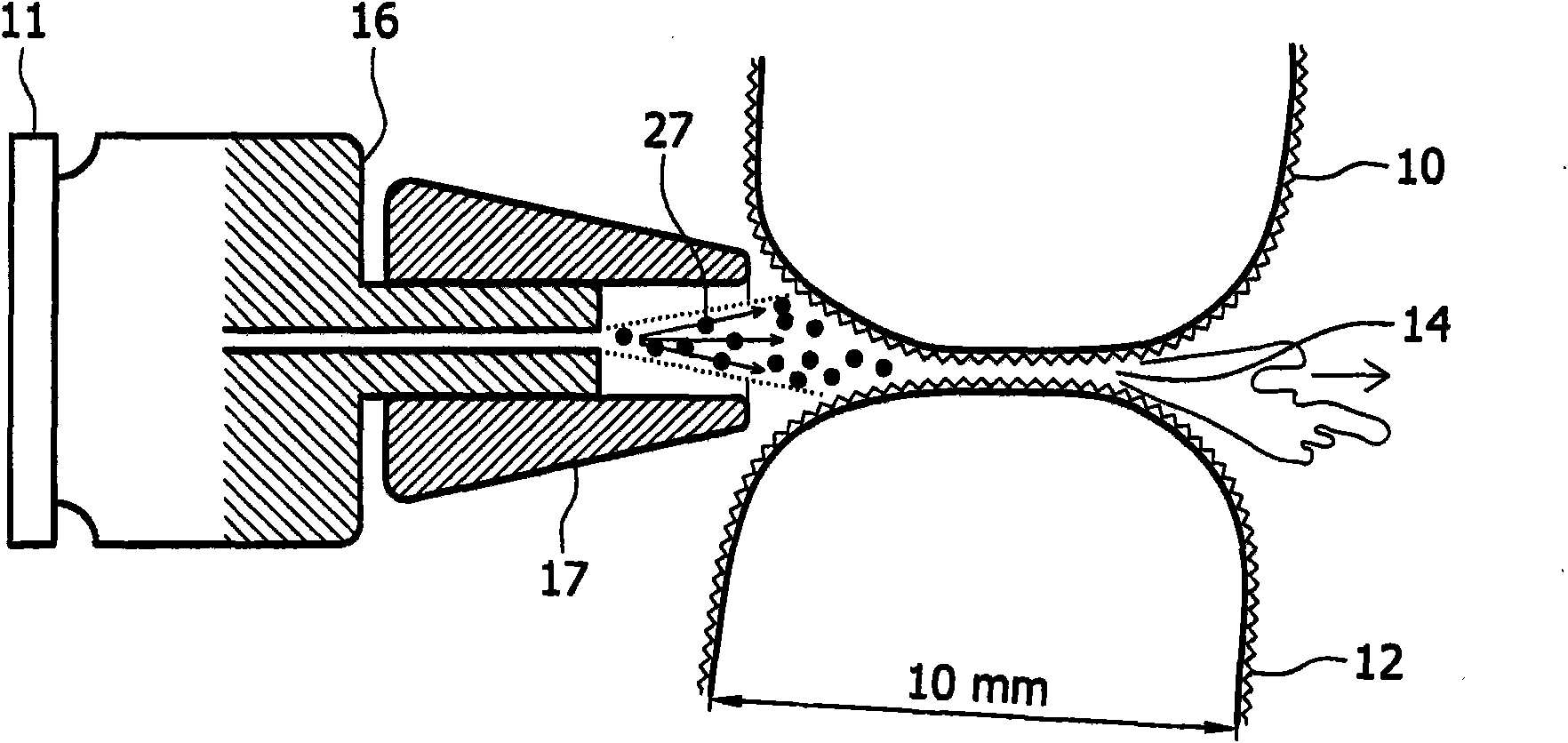

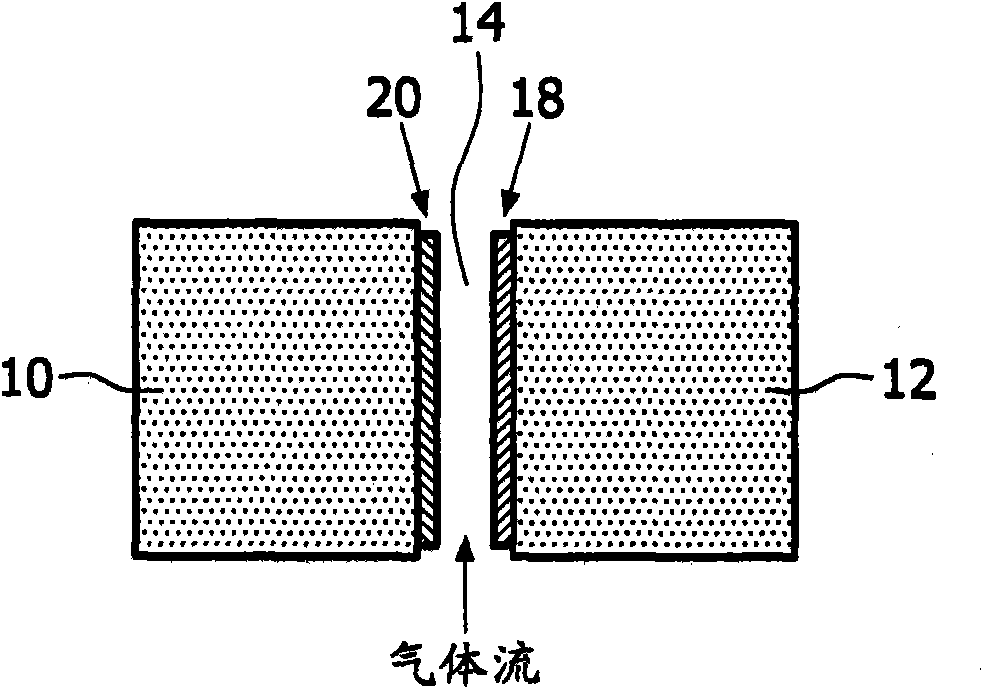

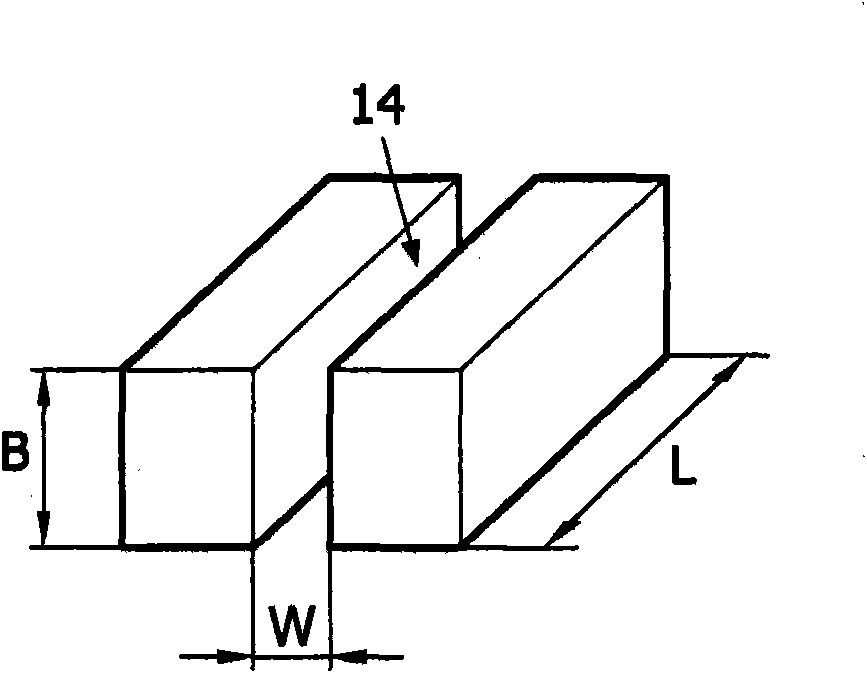

[0010] The apparatus described and illustrated herein produces a spray of liquid droplets that directly impinge on adjacent tooth crevice surfaces while simultaneously creating a thin film of liquid on the adjacent tooth crevice surfaces. The liquid can be water, or various other liquids with different viscosities. Apparatus for producing liquid droplet ejection are well known. An example is shown and described in published patent application WO2005070324 owned by the assignee of the present invention. The content of that application is hereby incorporated by reference. Typically, such devices produce a useful cleaning effect when the liquid droplets impact the tooth surface at a relatively narrow range of 90° relative to the tooth surface. These devices include gas-assisted implementations to accelerate liquid droplets by using high velocity gas.

[0011] The micro-droplets impact the tooth surface and remove the biofilm plaque present on the tooth. The shear stress requi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com