Restoring method of eroded defective products of amorphous silicon cells and special device

A technology for solar cells and repair methods, applied in the production field of amorphous silicon solar cells, can solve problems such as reduced conversion efficiency of cells, hot spots, and reduced service life of cells, and achieve good economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical scheme of the present invention is described in detail below in conjunction with accompanying drawing:

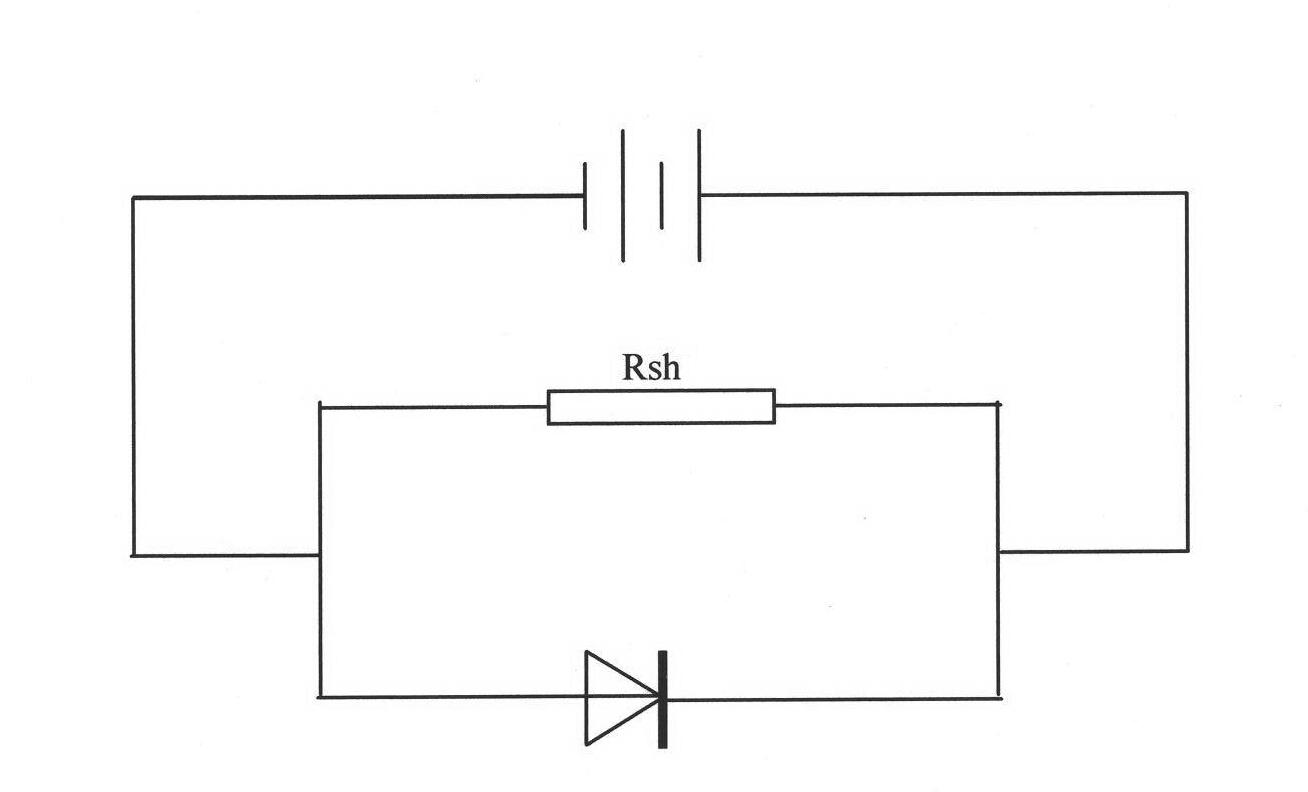

[0026] The circuit principle of the method for repairing defective amorphous silicon solar cell etching products described in the present invention is as attached figure 1 shown.

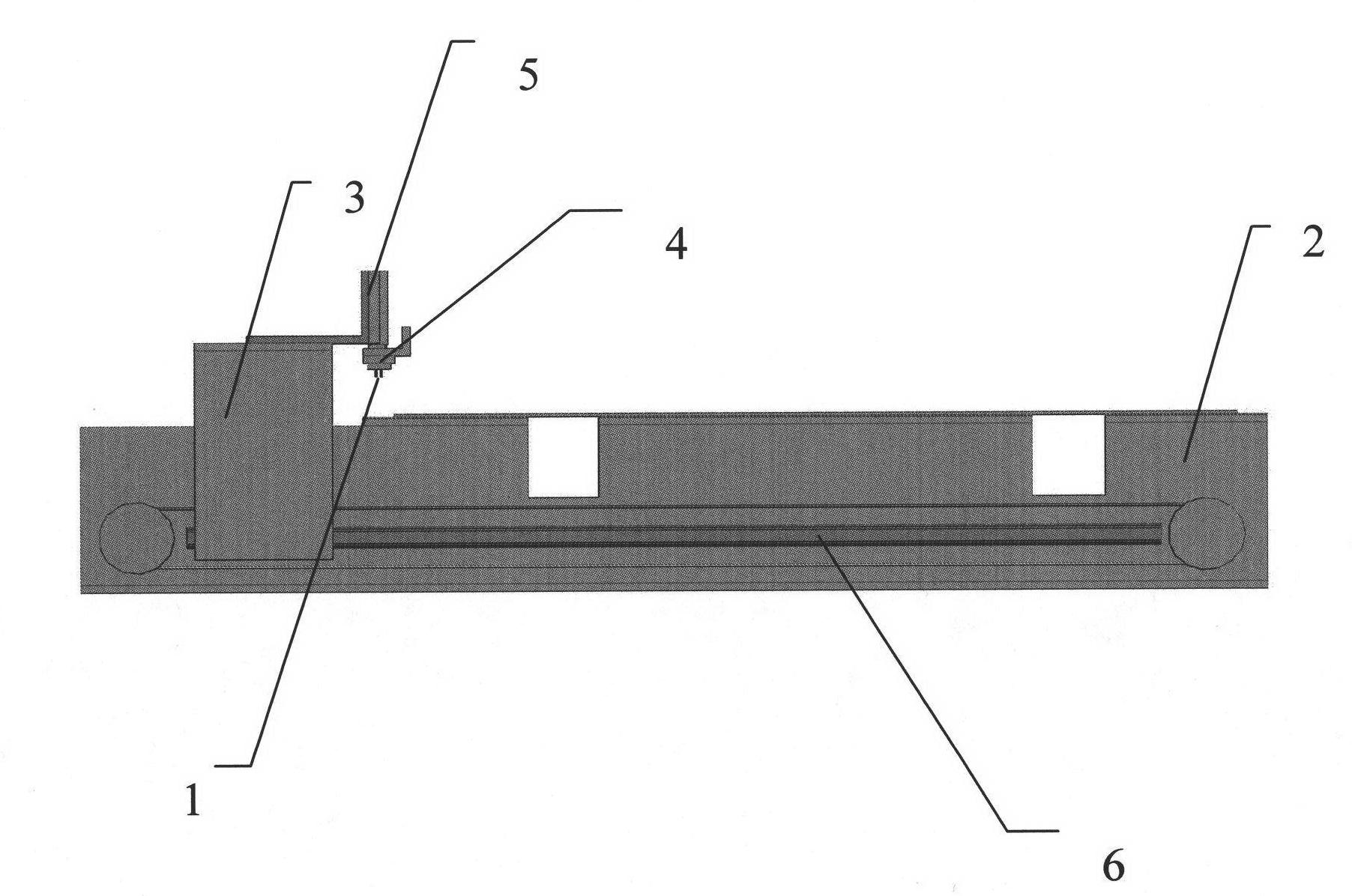

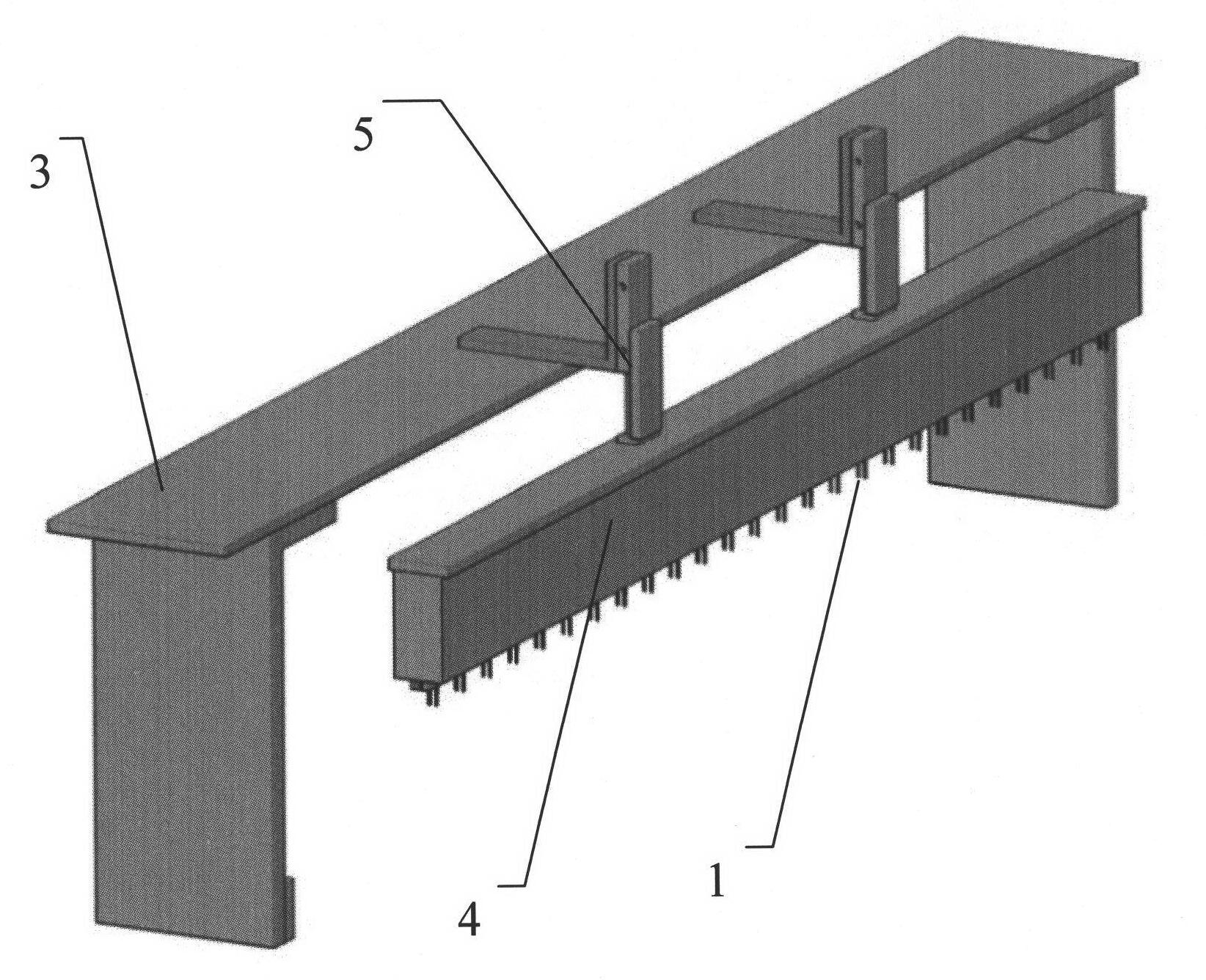

[0027] The special device for the repair method of the bad etching of amorphous silicon solar cell of the present invention, such as figure 2 , image 3 As shown, it includes a DC power supply with adjustable output voltage, a conductive probe 1, an operating platform 2, a probe base 4, and a probe base fixing bracket 3; the probe base fixing bracket 3 and the side of the operating platform 2 pass through a transverse transmission mechanism 6 connected, the transverse transmission mechanism 6 can make the probe base fixing bracket 3 slide along the direction parallel to the table top of the operating platform 2; the probe base 4 is connected with the probe base fixing brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com